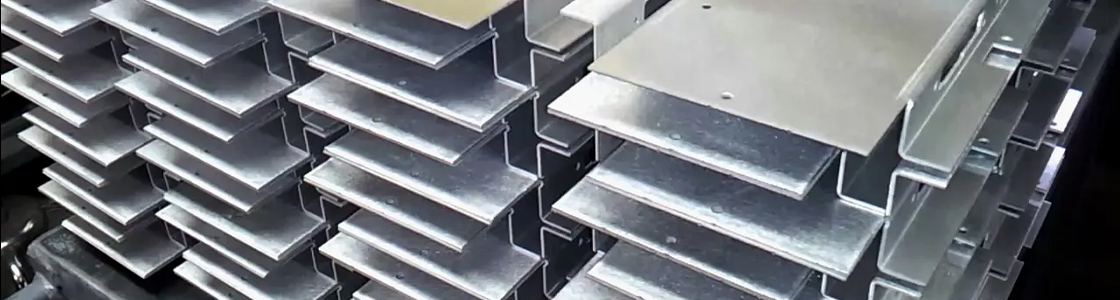

Sheet Metal Fabrication Services - Custom Sheet Metalwork for Prototypes and Production

Among the various manufacturing methods available today, sheet metal fabrication remains one of the most common methods manufacturers use to create metal objects for a wide range of industries.

Depending on the sheet metal you are using, you can use sheet metal parts in various industries, ranging from home appliances to the aerospace industry. The way sheet metal suppliers use rapid sheet metal will vary based on their functions. For instance, copper sheets are more suitable for electronic components. Meanwhile, the stainless-steel sheets will be ideal for making chassis and other vital fixtures by sheet metal contractors. You can also use sheet metals to produce various equipment enclosures and housings, such as PC and smartphone cases. Sheet metal fabrication services allow you to create your custom design, making it even more flexible for you to use in other applications. Medical industries also use metal parts fabrication to develop various medical equipment and tools. Some sheet metal materials are resistant to bacterial infection, which means they will be healthy for the patients.

Custom sheet metal has the characteristics of being lightweight, high strength, electrically conducive, low cost, and a good performance from large-scale mass production. With the increasingly wide application of cutting sheet metal, sheet metal design has become an essential part of product development. The excellent design shall not only meet the requirements of the product's features and application but also make the stamping die manufacturing simple and help to lower costs. As a professional sheet metal contractor, TEAM Rapid offer professional sheet metal parts fabrication services, and we can help you to get your part at a low cost! Request a sheet metal bending quote now!

How Sheet Metal Fabrication Works

Making sheet metal manufacture parts works in a few steps. The steps involved in this process include blueprint Preparation, design creation, metal fabrication, and product finalization.

1.Blueprint Preparation Before Going Ahead Sheet Metal Fabrication Services

It is the first step you will need to go through in custom sheet metal fabrication. You will need to prepare the blueprint to create the sheet metal prototypes, parts, and components for your project. With the rapid sheet metal process, the blueprint will act as the overall design of the product you want to produce. The metal prototypes, parts, and components production will need to follow the blueprint you have prepared.

2.Design Creation of Sheet Metalwork

This step will involve creating a workable design based on your prepared blueprint. The blueprint will contain only the general design idea for your prototypes, parts, and components. In the design creation phase, you will need to expand such a general idea into a workable design, which you will use to produce the metal objects using the sheet metal fabrication services.

This includes providing the 3D design for the blueprint, coloring the parts, determining the materials for each sheet metal part, and so on. You will need to turn the blueprint into a readable design that can be applied on the sheet metal bender, sheet metal cutter, sheet metal nibbler, etc.

3.Custom Sheet Metal Fabrication

After getting the design ready, it's time for you to put it into how to cut sheet metal. The sheet metal cutters will follow your design requirements and process the sheet metals according to your expected metal object design.

The sheet metal manufacture phase involves various processes, such as bend sheet metal, cutting sheet metal, sheet metal brake, perforated metal sheet, joining, punching, forming, and many others. Then, the equipment will perform this process according to the programmed calculations for volume production, and you will get the end product that resembles the design requirements you expected earlier.

4.Product Finalization

Now, your rapid sheet metal parts and components are ready. However, after completing the custom metal sheet manufacturing process, there might be additional manufacturing processes you need to perform to complete the product. This process might not be necessary, but you will still need to do it if your project requires it.

The product finalization step might include adding a specific finish to the rolled sheet metal object, painting the metal object, and so on. This process will become vital if you want to prepare the product for commercial distribution right away.

The Benefits of Sheet Metal Manufacture

Custom sheet metal manufacturing offers various benefits that other machining processes might not give you. For instance, custom metal sheet parts are affordable, even more so for aluminum sheet metals.

With their affordable prices, it's easier for you to produce custom metal sheet parts and components with a minimal budget. There are also various wholesale sheet metal materials you can use for your production process, which will allow you to pick the best sheet metal supplier to help with your projects.

● Precise and Accurate Designs.

Using the cut sheet metal process, you can create metal objects such as sheet metal brakes, sheet metal panels, etc., with detailed and accurate designs. The sheet metal materials are very easy to shape by sheet metal shear and can follow any design of the object you want to produce.

● Sheet Metalwork Is Better than Plastics.

Metal sheets 4x8 are much stronger and more durable than plastic materials. You can rely more on sheet metals for long-term usage, making them suitable for various applications across various industries.

● Cheaper Costs for High-Volume Sheet Metal Manufacture.

Galvanized sheet metal 4x8 materials are also very cost-effective, meaning you don't need to spend too much money to produce metal objects with a metal sheet cutter. The higher your production volumes, the cheaper the production costs will be.

● Pressure and Corrosion Resistant.

Galvanized metal sheets will not rust, and they can withstand high pressure. Thus, you can use metal objects made by sheet metal cutting tools for various equipment for the best long-term use. With its corrosion-resistant property, metal objects with suitable sheet metal thickness can also withstand regular wear and tear.

● Smooth Finishes.

The smooth finishes of the metal objects made by sheet metal tools can also have a good finish. Typically, it needs no other post-finish process you need to do to smoothen the surface of the metal objects made in 20 gauge sheet metal. However, you can also apply various finishing options to the metal objects you have produced, which will be optional for you to use.

Sheet Metalwork Fabrication Services

How to cut sheet metal? Many processes are available on our end to build your parts rapidly. Bending, Stamping, Extrusion, and laser cutting are commonly used to produce your sheet metal parts at low cost without compromising quality. As professional sheet metal contractors, our sheet metal contractors can offer us reasonable sheet metal prices for various materials. Contact us to learn more about us and get a sheet metal bending quote.

Sheet Metal Bending

Sheet metal bending is commonly used to produce a V-shape, U-shape, or channel shape along a straight axis in ductile materials sheet metal bending tools. Box and pan brakes, brakes for sheet metal presses, and other specialized machine presses are the mechanical equipment used for sheet metal bending.

Sheet Metal Stamping

Sheet metal stamping is a cold-forming process that uses extreme force and speed to alter the shape of sheet metal permanently. It involves placing flat sheet metal, in either coil or blank form, into a stamping press. A tool and die surface in the press form the metal into the desired shape.

Sheet Metal Laser Cutting

Laser cutting is a process that uses a focused laser beam to meld material in a localized area. The assisted gas jet is used to eject the molten material and create a kerf. It severs metallic plates with high accuracy and exceptional process reliability. We can process a continuous cut by moving the laser beam or workpiece under CNC control. Laser cutting aluminum extrusion is widely used in our projects.

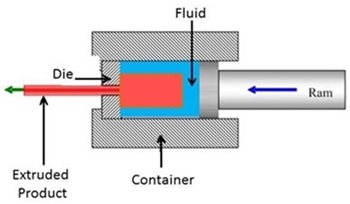

Aluminum Extrusion

Aluminum Extrusion is a metal-forming process used to create a metal or plastic workpiece by pushing through a die of the desired cross-section. This process is extensively used in pipes and steel rod manufacturing and can be applied in making solid, hollow, and semi-hollow parts in desired cross-section shapes in sheet metal. Request a quote for aluminum extrusion!

The Materials Used in the Sheet Metal Fabrication Process

Sheet metal fabrication offers plenty of flexibility for fabricators to use various sheet metal types to complete their production requirements. Each sheet metal will provide specific characteristics or properties that suit certain applications best. For instance, copper might be best for producing electrical components, whereas aluminum will be best for making durable and lightweight enclosures or housings.

●Aluminum.

Aluminum is lightweight, but it is also strong enough to withstand normal wear and tear. This sheet metal is also resistant to corrosion; sheet metal fabricators use aluminum sheets to build exterior and interior metal parts. This is perhaps the most common sheet metal material manufacturers will use for various applications. We can get aluminum sheet metal on sale quickly on the market; the 4x8 metal sheets price is low, and good for sheet metal fabrication services.

●Copper.

Copper is a malleable metal widely used by sheet metal fabricators. You can use this metal for various metal objects since it is very easy to shape. It has excellent electrical and thermal conductivity. This is a standard metal used in electrical components and medical tools.

●Brass.

Brass is a mixture of zinc and copper, and the ratio of the mix will depend on the qualities or properties you want from it. This sheet metal helps create electrical components by sheet metal suppliers, as it has excellent electrical conductivity. Even more so, brass is also a sturdy metal, making it suitable for lengthening the usage period of various electrical equipment.

●Steel.

There are various steel metals you can use in sheet metal fabrication. Stainless steel is the most common one used by sheet metal suppliers. It is sturdy and durable and might be the strongest sheet metal you can use for sheet metal fabrication. Thus, stainless steel is suitable for various metal parts fabrication that requires excellent sturdiness and durability. The other steel types for rapid manufacturing include carbon and regular steel.

Frequently Asked Questions About Sheet Metalwork

A. What materials are available at TEAM Rapid for my sheet metal parts?

TEAM Rapid has a mature supply chain as one of the best sheet metal contractors. We can get different sheet metals near me quickly; we usually suggest our customers make metal parts in Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc.

B. What surface finish can I have for my sheet metal parts?

At TEAM Rapid, we offer arranges of post finish such as Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, sandblasting, etc. for your needs.

C. What's kinds of information you need for a quote?

To get a sheet metal bending quote quickly, please kindly provide us with the following information together with your inquiry.

1. Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

2. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3. Surface treatment (powder coating, sandblasting, planting, polishing, oxidization, brushing, etc.)

4. Quantity (per order/ per month/ annual)

5. Any particular demands or requirements, such as packing, labels, delivery, etc.

D. What shall we do if we do not have drawings?

As one of the best sheet metal contractors, we have the suggestions:

1. Please kindly send your sample to us. We will study it and give you the best solution.

2. If the sample is unavailable, please send us pictures or drafts with dimensions (Sheet Metal Gauge Thickness, Length, Height, Width), and we can give you a rough estimation.

E. How can I know the status of my project without visiting your company?

Our project manager will offer a detailed production schedule and send weekly reports with photos or videos timely to show the machining progress. We have a strict inspection system to guarantee every part is thoroughly inspected before shipment.