Talking about the 7 Components Used in Injection Molding Process

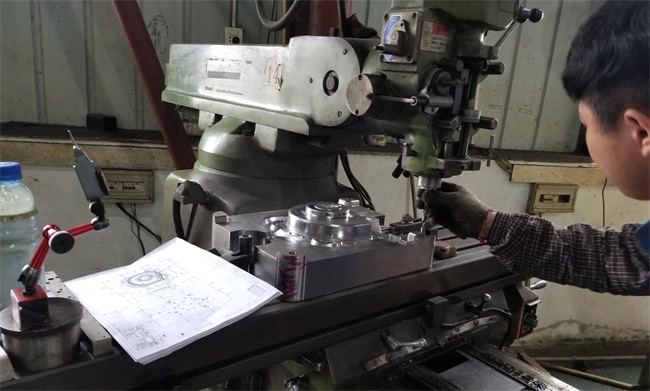

We got question from our customers about injection molding process lately. Here, we are going to have a brief introduction of the 7 components used in injection molding. It relates the system of Injection Mold Tooling and rapid prototype tooling.

According to the mold structure and basis function, it can be divided into the following 7 components: runner system, temperature control system, part forming system, exhaust system, guiding mechanism, slider and pulling mechanism, and ejection system. Let’s have a brief talk about these in injection molding:

7 components andInjection Molding Process

Runner system

The runner system is tunnels for conveying the melted plastic from nozzle of injection machine to cavity. Main and branch flow path, cold material well, gates are the common components of runner system.

Temperature control system

We can adjust the mold temperature via temperature control system, and there is cooling system or heating system depending on the requirements.

Part forming system

It refers to the parts that compose the mold cavity. Punch, die, core, curved lever, forming ring and the insert etc are main components of this system.

Exhaust System

It is mainly for excluding the gas raise during injection process. The exhaust tank size is different depending on the type of resin.

Guiding mechanism

It mainly plays the role of guiding, positioning and bearing the lateral pressure and ensure the mold close and open correctly and smoothly.

Slider and pulling mechanism

Depending on the different mold structure, the side parting/undercuts can be released by slider or hydro-cylinder.

Ejection system

It is the action after part forming, and is composed of ejector plate, push rod, ejector retainer plate, pulling rod and reset rod.

TEAM Rapid Specializes inInjection Molding

TEAM Rapid provides the best solution to meet your different volume manufacturing needs. We offerRapid Prototype Tooling, rapid tooling, production tooling according to your requirements to catch your timeframe and budges, our experienced engineers understand your standard and can help you turnaround your part quickly. Contact us at [email protected] today and get a rapid manufacturing quote from us!