January 5, 2022 July 25, 2023

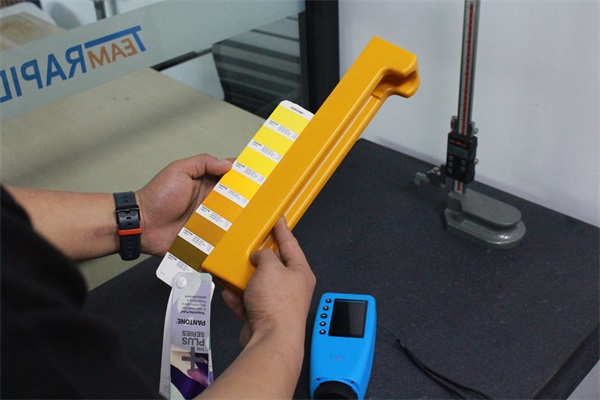

Injection Molding Color is important as color for injection molded product could be a huge difference in the success of the product. For example, consumer products, different colors and appearances differentiate your products from the one next to them on the shelf. The right color of injection molded products can take a person from just looking to must have..