3D Print Services - Flexible Manufacturing, Delivered in Days

TEAM RAPID provides comprehensive 3D printing services to help innovators, designers, and engineers turn ideas into reality.Our advanced additive manufacturing solutions can fully meet your needs of high-precision prototypes, functional parts, or low-volume production in speed, accuracy, and quality— all without the long lead times of traditional tooling.

What is 3D Printing

3D printing is a kind of additive manufacturing processes, which can create three-dimensional objects directly from digital 3D models. Differ from traditional manufacturing, which removes material through cutting or molding, 3D printing builds the objects layer by layer, adding material only where it is needed.

This technology allows for:

- Rapid prototyping: Quickly turning concepts into physical models.

- Complex geometries: Producing shapes and features that are difficult or impossible with traditional methods.

- Custom or low-volume production: Making small batches of parts without expensive tooling.

- Material versatility: Using plastics, metals, resins, and even flexible or composite materials.

With 3D printing, designers and engineers can iterate faster, reduce waste, and bring products to market more efficiently.

How 3D Printing Works

3D printing is an additive manufacturing process that turns the designed models into physical parts layer by layer.Tools, molds, or cutting forces are no needed for 3D printing, the process builds exactly what you need directly from data. This makes it ideal for fast prototypes, functional testing, and complex shapes that traditional processes struggle to produce. Here’s how the process works:

| Step No. | Process Stage | Description | Key Elements & Technologies |

| 1 | Create or Upload a 3D Model | The foundation of the process, where the exact dimensions and geometry of the part are defined digitally. | 3D CAD model in required formats like STL, OBJ, or STEP. |

| 2 | Select 3D Printing Method | Choosing the appropriate machine/technology based on part requirements (material, accuracy, volume, etc.). | Different printing processes require different types of 3D printers. |

| 3 | 3D Printing Materials | Selecting the medium used to build the final object, which dictates the part's physical properties. | Plastics (e.g., PC, PLA), Powders, Resins, Metals, and various other specialized compounds. |

| 4 | Slicing the Model | Preparing the 3D design file for the printer by digitally dividing it into thin layers. This is necessary for the printer to build the object layer by layer. | Slicing Software is used to define: Toolpaths, Support structures (if needed), and Printing parameters. |

| 5 | Layer-by-Layer Printing | The actual fabrication where the printer builds the part by depositing or solidifying material based on the sliced file. | SLA/Resin: Laser cures liquid resin. SLS/Nylon: Laser sinters powder. FDM: Heated filament is extruded. |

| 6 | Cooling and Support Removal | Allowing the printed part to solidify and performing initial cleaning to make the part structurally sound. | Cooling/hardening time, Removing supports, Cleaning excess resin/powder, Trimming/sanding rough edges. |

| 7 | Post-Processing and Finishing | Enhancing the printed part's final appearance, surface quality, and performance to meet end-use specifications. | Polishing, Painting, Coating, Machining, and Dyeing. |

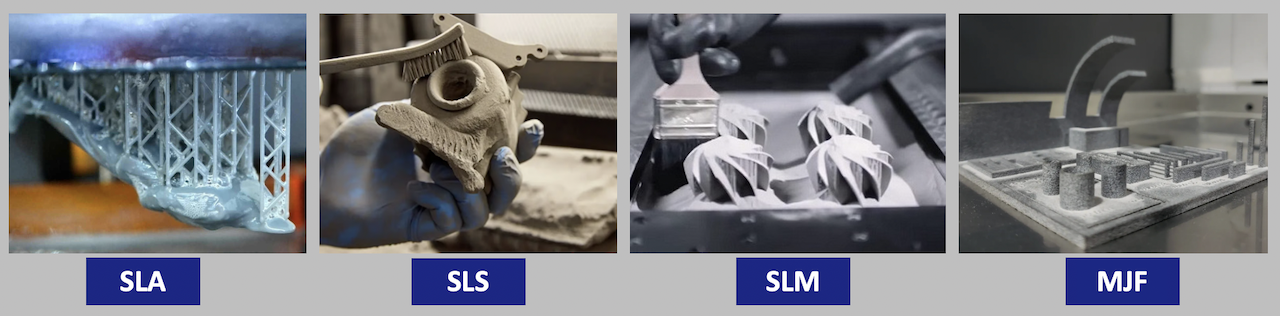

Types of 3D Printing Methods at TEAM RAPID

TEAM RAPID offers a wide range of advanced 3D printing technologies to meet different prototyping and production needs. SLA, SLS, MJF, SLM are the available 3D printing methods at TEAM RAPID. These methods directly use the product’s three-dimensional computer data to achieve a product prototype in plastics or metal based on the principle of layer-by-layer stacking of discrete layers:

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)uses a laser to fuse thermoplastic powder to get solid part layer by layer, it is a powder-based 3D printing process.Thanks to the surrounding powder supports during part printing, there are no additional support structures are needed, which allows to produces highly complex and functional designs efficiently.

SLS parts has excellent strength, durability, and heat resistance, but not very good appearance. This method is ideal for functional prototypes and end-use components. It is also well-suited for small-batch production where consistency and mechanical performance are important.

Stereolithography (SLA)

Stereolithography (SLA)uses a UV laser to cure liquid resin to create exceptional surface finish and fine details parts. It is a high-precision 3D printing. SLA is widely chosen for parts or components that appearance, accuracy, and smooth surfaces are critical.

This process is widely used for visual prototypes, concept models, and detailed parts that require tight tolerances. A variety of resin materials are available, including transparent, rigid, flexible, and high-temperature options, to meet different design needs.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is one kind of popular metal 3D printing process, it fully melts metal powder using a high-energy laser to create dense, high-strength metal parts. Parts made by SLM performs excellent mechanical properties and can be used for demanding industrial applications.

SLM can produce complex metal geometries parts, including internal channels and lightweight structures that are difficult or impossible to make via traditional manufacturing methods. It is suitable for both prototyping and low-volume metal part production.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is an industrial 3D printing technology.Following by thermal energy to solidify the material that builds parts by selectively applying fusing agents to powder layers.This process delivers high dimensional accuracy, uniform strength, and excellent repeatability.

Functional prototypes and production-ready parts usually made by MJF, the process offers faster turnaround times and consistent quality across multiple builds. Parts produced with MJF typically have balanced mechanical properties in all directions.

Summary & Comparison of These Four 3D Printing Methods

| 3D Printing Method | Material Category | Common Material Options | Typical Tolerance* | Material Characteristics | Typical Use |

|---|---|---|---|---|---|

| SLA | Photopolymer Resin | Standard rigid resin, high-detail resin, transparent resin, tough resin, flexible resin, high-temperature resin | ±0.1 mm or ±0.1% (whichever is greater) | Very smooth surface, high detail, excellent accuracy; moderate strength | Appearance models, design prototypes, medical and display parts |

| SLS | Thermoplastic Powder | Nylon PA12, Nylon PA11, glass-filled nylon | ±0.3 mm or ±0.3% (whichever is greater) | Strong, impact resistant, good thermal stability | Functional prototypes, enclosures, mechanical components |

| SLM | Metal Powder | Stainless steel, aluminum alloy, titanium alloy, tool steel | ±0.2 mm or ±0.2% (whichever is greater) | High strength, dense metal parts, excellent mechanical performance | Structural metal parts, tooling, aerospace and medical components |

| MJF | Thermoplastic Powder | Nylon PA12, Nylon PA11, glass-bead filled nylon, flame-retardant nylon (optional) | ±0.2 mm or ±0.2% (whichever is greater) | Consistent strength, good fatigue resistance, uniform properties | Functional prototypes, production housings, batch production |

Need help to choose the right 3D printing method

Contact TEAM RAPID today — our engineering team will review your design and recommend the most efficient solution for your project.How to Choose the Right Method

- When appearance and precision matter most - Choose SLA

- When needs strong plastic parts with complex geometry - Choose SLS

- When metal strength and durability are required - Choose SLM

- When needs fast turnaround and production-ready plastic parts - Choose MJF

The Evolution and Key Benefits of 3D Printing Services

The roots of 3D printing technology trace back to the 1980s in Japan. Hideo Kodama pioneered the first rapid prototyping method using an early iteration of Stereolithography (SLA). While the technology has advanced significantly since those initial patents, the core mission remains the same: transforming digital designs into physical realities with unprecedented speed. Today, 3D printing is no longer a niche tool for engineers—it is a cornerstone of modern manufacturing. Here are the primary benefits of utilizing a professional 3D printing service:

1. Limitless Design Flexibility

Unlike traditional manufacturing, which is often restricted by tool access and mold geometries, 3D printing allows for total creative freedom. You can personalize and iterate on complex designs, organic shapes, and intricate internal structures that would be impossible to create otherwise.

2. Accelerated Prototyping and Production

3D printing is the gold standard for Rapid Prototyping. It allows manufacturers to create physical models in a matter of hours. This speed enables you to test form, fit, and function quickly, identifying necessary adjustments before committing to expensive, large-scale production.

3. Precision for Small and Complex Components

3D printing and scanning services are ideal for producing small, high-detail components. By printing various iterations of a part, you can test different fits within your product assembly. This "sample-first" approach reduces the risk of assembly errors in the final production run.

4. Accessibility and Cost-Effectiveness

3D printing technology is more accessible than ever. What was once reserved for massive industrial plants is now available to small businesses and individual innovators. As the technology has matured, the cost of materials and machine time has decreased, making custom 3D printing a budget-friendly solution for projects of any size.

5. On-Demand Printing and Space Efficiency

With 3D printing, there is no need to maintain a massive inventory or dedicated storage space. You can print parts exactly when you need them—a "print-on-demand" model that saves on overhead and logistics. Whether you are looking for a local solution or a global partner, professional parts can now be delivered to your door in just a few days.

Professional 3D Printing Services from TEAM RAPID

TEAM RAPID has specialized in 3d printing for years. We have been offering professional 3d printing services to our customers worldwide. From individuals to Fortune 500 companies, they are happy with our services. We provide 3d printing services for hobbyists too! Please email us at [email protected] to get the best online 3d printing services.

3D Printing Applications

3D printing is widely used nowadays, especially in the product development and low-volume manufacturing stages, it covers from early concept validation to functional end-use parts.Benefits from it’s flexibility, speed, and design freedom, making it an ideal solution for industries that need fast iteration, customization, and complex geometries.

Product Design & Engineering Validation

Before going ahead to tooling, designers and engineers can make the parts via3D printing, which allows to quickly evaluate form, fit, and assembly before committing to tooling. Physical models help identify design issues early, reduce development risk, and accelerate time-to-market.

Prototypes & Low-Volume Manufacturing

Due to the development of engineering-grade materials and advanced printing technologies, 3D printed parts now can withstand mechanical stress, heat, and chemical exposure. These prototypes are suitable for performance testing, presentation, user trials, and real-world validation.For small batch production or short-run manufacturing, 3D printing eliminates the need for expensive molds. It is commonly used as a bridge solution before mass production, or for products with limited demand.

What Parts or Components Are Made with 3D Printing

| Category | Typical 3D Printed Parts / Components | Why 3D Printing Is Used |

|---|---|---|

| Prototypes & Concept Models | Appearance models, form studies, proof-of-concept parts | Fast iteration, low cost, quick design validation |

| Functional Mechanical Parts | Brackets, mounts, clips, gears, linkages | Functional testing, complex geometry, no tooling |

| Enclosures & Housings | Electronic enclosures, control boxes, sensor covers | Precise fit, easy design changes, custom shapes |

| Jigs & Fixtures | Assembly fixtures, checking gauges, drill guides | Faster production setup, cost-effective tooling |

| Low-Volume Production Parts | Short-run components, spare parts, replacement parts | No mold cost, ideal for small batches |

| Lightweight & Complex Parts | Lattice structures, internal channels, optimized parts | Weight reduction, impossible with traditional methods |

| Medical & Dental Components | Surgical guides, anatomical models, dental trays | High accuracy, customization, patient-specific designs |

| Automotive Components | Prototype vehicle parts, ducts, interior trim | Rapid development, design flexibility |

| Aerospace Components | Lightweight brackets, airflow parts, structural elements | High performance, reduced weight |

| Consumer & Industrial Products | Custom tools, wearable parts, appliance components | Customization, fast time-to-market |

3D Printing Development in China

Driving by strong market demand, advancing technology, and increasing adoption across industrial sectors,China’s 3D printing (additive manufacturing) industry is growing rapidly, especially in this decade. China is one of the world’s most dynamic markets for additive manufacturing

1. Fast-Growing Market

China’s 3D printing market has expanded significantly in recent years. From 2017 to 2022, the industry grew at a compound annual growth rate (CAGR) of around 21.8%. In 2023, the market size was estimated at about?447.9 billion (~$60–65 billion)and continues to expand rapidly. The industry is projected to exceed?630 billion by 2025, making China one of thelargest additive manufacturing markets worldwide.

2. Regional Clusters and Innovation

Additive manufacturing clusters have formed in major regions:

- Yangtze River Delta– industrial equipment and advanced manufacturing

- Pearl River Delta– consumer electronics and adaptable 3D printing applications

- Bohai Rim – materials and high-performance supplies

Emerging hubs in central and western China are focusing on automotive components and aerospace additive manufacturing ecosystems.

3.Trends & Future Growth

Looking ahead, China’s 3D printing market is expected to continue rapid growth through the end of the decade. The development outlook includes increased industrialization of additive manufacturing, deeper integration with digital manufacturing, IoT, and AI, and greater adoption in high-precision sectors. Materials innovation and broader industrial use cases will further expand the technology’s reach.

Our 3d Printing Online Services and Capabilities

TEAM RAPID provides professional 3D printing solutions by using multiple technologies and materials to match your application needs, whether you need prototypes, functional parts, or low-volume production components, we are here to help you with.

Our 3D printing facilities includes the following

Available Printing Capabilities

Specification

SLA

MJF

SLS

SLM

Min. Wall Thickness

0.6 mm (unsupported)0.4 mm (supported on both sides)

At least 1.0 mmAvoid overly thick walls

0.7 mm (PA12)Up to 2.0 mm (carbon-filled PA)

0.8 mm

Layer Height

25–100 um

~80 um

100–120 ?m

30–50 um

Max. Build Size

1400 × 700 × 500 mm

264 × 343 × 348 mm

380 × 280 × 380 mm

320 × 320 × 400 mm

Dimensional Tolerance

±0.2 mm(>100 mm: ±0.15%)

±0.2 mm(>100 mm: ±0.25%)

±0.3 mm(>100 mm: ±0.35%)

±0.2 mm(>100 mm: ±0.25%)

Standard Lead Time

4 business days

5 business days

6 business days

6 business days

Contact Us

TEAM RAPID has helped shape various companies in different industries, including medical, consumer electronics, film, archaeology, and numerous others. We help companies and individuals produce and manufacture their products at a much faster rate today. Want to learn more about our online 3d printing service? Contact our team at [email protected] today.

3D Printing vs. CNC Machining

3D printing and CNC machining are the two widely used processes that serving with different stages of product development and production. Engineers and designers can choose the most efficient process for their application when they know the differences of these two technologies.

3D printing

It is an additive process that creates parts by building material layer by layer from a digital model. This method allows material to be placed only where needed, enabling complex internal structures and design flexibility. 3D printing excels at producing complex geometries, such as internal channels, lattice structures, and lightweight designs that are difficult or impossible to make by CNC machining. Designers can implement quick changes without additional tooling.

CNC machining

Differ from 3D printing, it is a subtractive process that removes material from a solid block using precision cutting tools.CNC machining delivers high dimensional accuracy and excellent surface quality. It is ideal for functional and end-use components, especially for tight tolerances, flat surfaces, and critical mating features, which needs superior precision and consistency. Machined parts also maintain the full mechanical properties of the base material.

3D Printing vs. CNC Machining – Cost, Lead Time, Materials & Use Cases

| Comparison Aspect | 3D Printing | CNC Machining |

|---|---|---|

| Cost Efficiency | More cost-effective for prototypes, early-stage designs, and customized parts | More economical when precision and part performance are critical |

| Lead Time | Very fast turnaround with minimal setup | Slightly longer due to programming and setup |

| Production Quantity | Best for low-quantity and one-off parts | Suitable for low- to medium-volume production |

| Tolerance Requirements | Moderate tolerances, process dependent | Excellent for tight tolerances |

| Surface Finish | May require post-processing | High-quality surface finish directly from machining |

| Functional Performance | Suitable for form, fit, and basic function checks | Ideal for functional testing and end-use parts |

| Typical Use Cases | Concept models, visual prototypes, design validation, complex internal features, short-run production without tooling | Functional prototypes, precision mechanical components, structural parts, high-strength applications |

| Common Materials | PLA, ABS, PETG, Nylon, Polycarbonate, ULTEM/PEI, Resin, Metal powders (SLS/SLM) | Aluminum, Stainless Steel, Titanium, Brass, Copper, plastics (PEEK, ULTEM, Delrin, Nylon) |

FAQs — 3D Printing Services

TEAM RAPID combines advanced 3D printing technologies with expert engineering support to deliver competitive price 3D printed parts at fast, precise, and excellent function, no MOQ.

Yes, nearly all the possibly finish such as sanding, polishing, painting, plating, machining etc. are available at TEAM RAPID, which can be used to improve surface finish, strength, or aesthetics.

Yes. Our engineers can review your model, suggest design adjustments for manufacturability, and recommend the best technology and material to meet your goals.