CNC Machining Services - From Prototypes to Production

What is CNC Machining

CNC machining is a subtractive manufacturing process that a computer-controlled and programmed machine tools precisely remove material from a solid workpiece, producing parts with tight tolerances, consistent accuracy, and repeatable quality across metals, plastics, and composites.

How does CNC Machining Work

CNC machining is using computer-controlled instructions to remove material from a solid workpiece precisely. It is a digital design into a physical part process that contains several core steps:

CNC machining is using computer-controlled instructions to remove material from a solid workpiece precisely. It is a digital design into a physical part process that contains several core steps:

-

Part Design(CAD)

Designers use CAD software to create a 2D or 3D model of the part, defining geometry, dimensions, and tolerances.

-

Generate machine code (CAM)

The CAD file is converted intoG-code, which tells the CNC machine how to move—tool paths, speeds, feeds, and cutting depths.

-

Set up the machine

The operator loads the program into the CNC machine, secures the workpiece, and installs cutting tools.

-

Automated machining

The CNC machine follows the programmed instructions to cut, drill, mill, or turn the material with high precision and repeatability.

-

Deburr and finishing

The finished part removed from machine, and deburr, then may receive post surface finishing such as polishing, anodizing, or coating.

CNC Machining Development in China

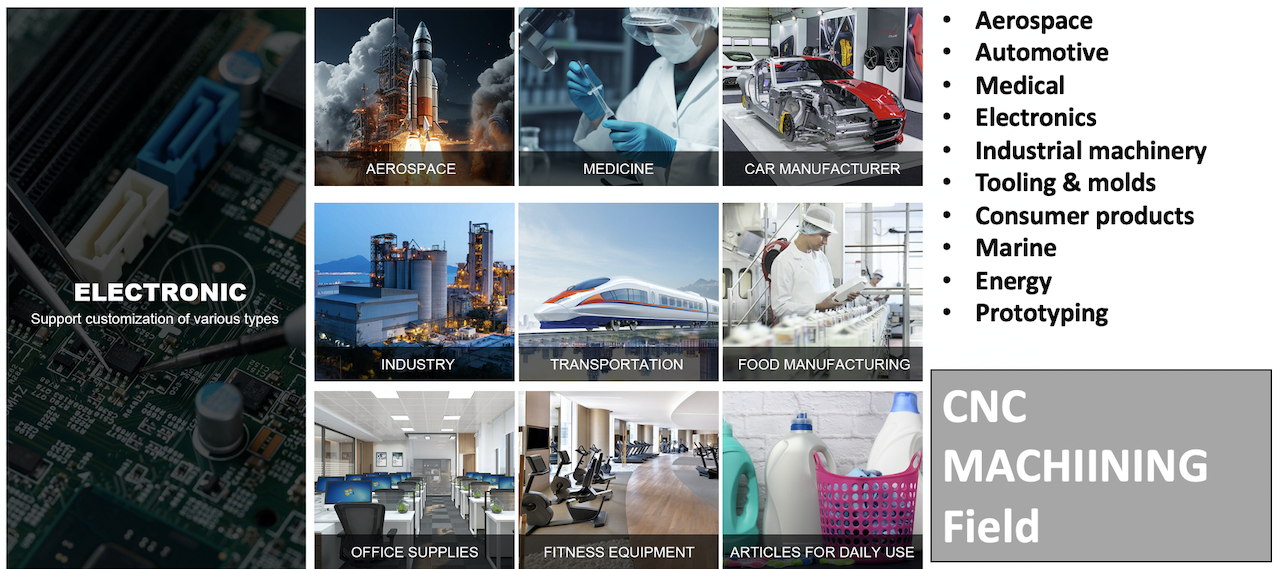

China now is a global leader in CNC machining field, the country offers a combination of advanced technology, skilled labor, and competitive costs.The China CNC machining is developing quickly, the industry has evolved rapidly, transforming from small, manual machining workshops into sophisticated factories in the past two decades, capable of producing high-precision components for aerospace, automotive, medical devices, electronics, and industrial equipment.

Historical Development

- Early 2000s: China’s CNC industry relied mostly on imported machinery and focused on simple mechanical parts. Local production was limited to low-precision components.

- 2010–2015: Investment in high-speed CNC machines, multi-axis centers, and CAD/CAM integration increased. Companies began serving global clients in aerospace and automotive sectors.

- 2015–2025: The industry embraced automation, smart manufacturing, and high-precision machining, producing complex parts such as molds, medical implants, and industrial prototypes at competitive rates.

How to Find Reliable CNC Machining Suppliers

high-quality parts, on-time delivery, and cost-effective production are the key factors to take into consideration when finding a trustworthy CNC machining supplier in China. Here’s how to find the right partner:

- Define Requirements– Specify materials, tolerances, part size, volume, and surface finish so suppliers can provide accurate quotes.

- Check Experience– Look for suppliers with relevant industry experience, certifications (ISO 9001, IATF 16949, AS9100), DFM expertise, and project portfolios.

- Verify Capabilities– Ensure they have the right multi-axis CNC machines, large-format capacity, inspection tools, and CAM/CAD systems.

- Request Samples– Test prototypes to evaluate accuracy, surface finish, and material performance.

- Check Reputation– Review testimonials, references, and past projects to confirm reliability.

- Assess Communication & Support– Choose suppliers who respond promptly, provide DFM guidance, and offer clear pricing and lead times.

- Evaluate Pricing– Compare multiple quotes, balancing cost with quality and services.

- Start Small– Begin with a pilot order to test consistency before scaling production.

- Build a Partnership– Long-term collaboration can speed up prototyping, improve pricing, and ensure priority support.

Good vs Poor CNC Suppliers – Quick Comparison

| Feature | Good CNC Supplier | Poor CNC Supplier |

|---|---|---|

| Experience | Years of CNC machining experience; proven track record | Little or no experience; limited project portfolio |

| Certifications & Standards | ISO 9001, IATF 16949, AS9100, or equivalent | No certifications; unknown quality standards |

| Engineering Support | Offers DFM guidance, prototyping advice, and technical consultation | Minimal or no design support; ignores manufacturability issues |

| Equipment & Capabilities | Multi-axis CNC machines, large-format capability, advanced inspection tools | Outdated or limited machines; cannot handle complex or large parts |

| Quality Control | Strict QC procedures, in-process inspection, CMM, tolerance checks | Minimal QC; inconsistent tolerances; frequent defects |

| Communication & Responsiveness | Clear, timely responses; transparent pricing and lead times | Slow or unclear communication; hidden costs or vague timelines |

| Prototype & Sample Support | Provides samples for testing before full production | No sample support or poor-quality prototypes |

| Reputation & References | Positive reviews, repeat customers, references available | Unknown reputation, no references, negative feedback |

| Pricing & Value | Competitive pricing with consistent quality | Extremely low prices but compromises quality |

| Reliability & Delivery | On-time delivery; capable of scaling production | Frequent delays; unreliable delivery schedules |

Overview of TEAM RAPID’s CNC Machining Services

TEAM Rapid Manufacturing Co., Ltd is a rapid manufacturing company who specializes in precision CNC machining for rapid prototypes and production.

Company details:

A Hong Kong–registered company with CNC machining facilities in Zhongshan, Guangdong Province, China that serves global customers from prototyping to production.

Our CNC Machining Capabilities

CNC Milling Services

TEAM RAPID equips with3-axis, 4-axis, and 5-axis CNC milling machines to produce simple to complex geometries parts, we have full capabilities to machine multi-face features in a single setup. CNC milling is an ideal process for parts requiring high accuracy, flat surfaces, pockets, slots, and complex contours.

- Prototypes and production runs

- High precision and repeatability

- Efficient machining of complex designs

- Reduced setup time for multi-sided parts

CNC Turning Services

Shafts, bushings, pins, and threaded components are usually made by CNC turning and lathe machining. Our Multi-function turning centers allow milling, drilling, and tapping operations to be completed in one cycle.

- Tight concentricity and surface finish

- Ideal for cylindrical and symmetrical parts

- High production efficiency

- Competitive prices for prototypes and production

Precision Grinding Services

TEAM RAPID applies surface grinding and precision grinding as secondary or final machining processes to achieve tight tolerances and superior surface finishes. When standard CNC machining cannot meet the required flatness, parallelism, or surface roughness, we usually use grinding as the secondary machining method.

- Excellent dimensional accuracy

- Improved surface quality and finish

- Ideal for hardened steel and precision components

- Long machining time

EDM Machining Services (Electrical Discharge Machining)

For parts that require intricate details, sharp internal corners, deep cavities, or machining of hardened materials, TEAM RAPID provides EDM.

Wire EDM

Wire EDM is used to cut complex profiles with extremely high precision. It is ideal for tooling components, dies, and mold inserts that require fine features and tight tolerances.

Sinker EDM

Sinker EDM (Ram EDM) is suitable for deep cavities, complex mold shapes, and internal features that are difficult or impossible to machine using conventional cutting tools.

- No cutting force on the workpiece

- Excellent for hard or heat-treated materials

- High accuracy for complex geometries

Secondary Machining & Support Processes

To deliver ready-to-use parts, we also provide a full range of secondary machining and finishing processes, including:

- Drilling, tapping, and reaming

- Polishing and deburring

- Assembly and part inspection

- Custom post-processing based on application requirements

Why CNC Machining Services at TEAM RAPID

Professional

Quality

Good Price

OEM & ODM

Service

Business Line

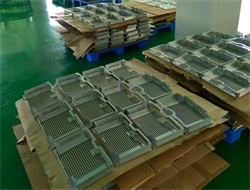

Our CNC Milling Cases

TEAM RAPID offers 3,4, and 5-axis CNC machining capabilities with tight tolerance down to 0.01mm.

Our CNC Turning Cases

We can accurately make CNC turning parts with complex internal features like spherical cavities, deep grooves etc.

Are you looking for precision CNC machining? Contact our team at [email protected] to get a competitive CNC machining quote now! We may have a new CNC machining technology or suggestions for your metal lathe projects!

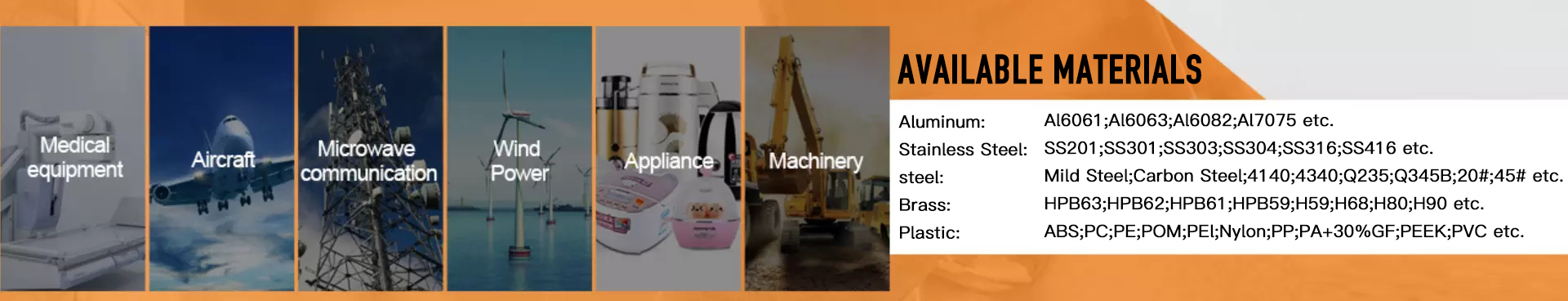

CNC Machining Materials

| Category | Material | Key Properties | Typical Applications |

|---|---|---|---|

| Aluminum Alloys | 6061 | Good machinability, strong, corrosion-resistant | Housings, frames, prototypes |

| 6082 | Similar to 6061, better for Europe standards | Structural parts | |

| 7075 | Very high strength, lightweight | Aerospace, high-stress parts | |

| 5052 | Good corrosion resistance, weldable | Sheet metal parts, tanks | |

| Steel – Carbon | 1018 | Easy to machine, cost-effective | Shafts, fixtures |

| 1045 | Stronger than 1018 | Gears, mechanical parts | |

| Steel – Alloy | 4140 | Tough, wear-resistant | Gears, shafts, tooling |

| 4340 | Very high strength | Heavy machinery parts | |

| Tool Steel | D2 | High wear resistance | Dies, cutting tools |

| H13 | Heat-resistant | Injection molds, hot tooling | |

| A2 | Tough, dimensionally stable | Punches, dies | |

| S7 | Shock-resistant | Impact tools | |

| Stainless Steel | 304 | Corrosion-resistant, food-safe | Medical, kitchen, chemical |

| 316 | Better corrosion resistance (marine grade) | Marine, chemical equipment | |

| 17-4 PH | Very strong, corrosion-resistant | Aerospace, high-performance parts | |

| Titanium | Grade 2 | Good corrosion resistance | Medical devices |

| Ti-6Al-4V (Grade 5) | Very strong, lightweight | Aerospace, implants | |

| Copper & Alloys | Copper | High electrical/thermal conductivity | Heat sinks, electrodes |

| Brass (C360) | Excellent machinability | Fittings, connectors | |

| Bronze (C932, C954) | Wear-resistant | Bushings, bearings | |

| Phosphor Bronze | Fatigue-resistant | Springs, connectors | |

| Beryllium Copper | Strong + conductive | Mold inserts, connectors | |

| Nickel Alloys | Inconel 625 | Heat & corrosion resistant | Turbines, aerospace |

| Inconel 718 | High strength at high temp | Jet engines | |

| Monel | Seawater resistant | Marine parts | |

| Hastelloy | Chemical resistant | Petrochemical equipment | |

| Pure Nickel | Corrosion-resistant | Plating, chemical parts | |

| Magnesium | AZ31, AZ91 | Ultra-lightweight | Aerospace, electronics |

| Plastics – Standard | ABS | Tough, impact-resistant | Enclosures, prototypes |

| PMMA (Acrylic) | Transparent, smooth finish | Lenses, displays | |

| Polycarbonate (PC) | High impact resistance | Protective covers | |

| PET / PETG | Clear, good machinability | Medical housings | |

| PE / HDPE | Chemical-resistant | Tanks, lab parts | |

| UHMW-PE | Very low friction | Conveyor guides | |

| Plastics – Engineering | Nylon (PA6, PA66) | Wear-resistant | Gears, bushings |

| POM / Delrin | High dimensional stability | Precision parts | |

| PEEK | High-temp, chemical-resistant | Aerospace, medical | |

| PPS | Heat & chemical resistant | Automotive, electronics | |

| PI (Vespel) | Extreme heat resistance | Semiconductor tools | |

| PTFE (Teflon) | Very low friction | Seals, gaskets | |

| G10 / FR4 | Electrical insulation | PCB fixtures | |

| Composites | Carbon Fiber | Very strong, lightweight | Aerospace, racing |

| Fiberglass | Strong, insulating | Electrical parts |

Most Popular CNC Machining Materials

- Aluminum— #1 most used: lightweight, easy to machine, corrosion-resistant, widely available.

- Carbon (Mild) Steel— #2: strong, low cost, used for most industrial parts.

- Stainless Steel— top choice when corrosion resistance is required.

- Alloy Steel— used for high-strength, wear-resistant components.

- Brass— very easy to machine, good conductivity, widely used for fittings and connectors.

- Plastics (ABS, POM/Delrin, Nylon)— heavily used for prototypes, gears, and functional parts.

- Titanium— popular in high-tech industries, but lower volume due to high cost.

CNC Machining Applications

TEAM RAPID stores more than 50 engineering-grade metals and plastics that are suitable for various part applications and industries. Contact our engineering team to get suggestions not only for the CNC machining aluminum but also for other materials.

Post-Finish Options at TEAM RAPID

TEAM Rapid proudly offers an extensive selection of professional post-finishes to supplement our manufacturing processes, giving you everything you need for a standout prototype or market-ready product. Here are some post-finish options for CNC plastic machining and CNC metal machining services.

| Aluminum | Stainless Steel | Steel | Plastic | Brass |

| Clear Anodized | Polishing | Zinc Plating | Plating | Gold Plating Machine |

| Color Anodized | Passivating | Nickel Plating | Painting | Electroplating |

| Sandblast Anodized | Sandblasting | Chrome Plating | Polishing |

|

| Chemical Film | Laser Printing | Oxide Black | Sand Blasting |

|

| Brushing |

|

Carburized | Laser Printing |

|

| Polishing |

|

Heat Treatment | Silk Printing |

|

| Plating |

|

Painting |

|

|

| Painting |

|

Powder Coated |

|

|

| Powder Coated |

|

Electroplating |

|

|

| Laser Printing |

|

|

|

|

| Silk Printing |

|

|

|

|

CNC Precision Machining Working Flows at TEAM RAPID

Our dedicated project managers will keep you posted on every detail of your ongoing China CNC machining projects through photos, videos and reports; we guarantee you know the project status. Contact us for CNC precision machining projects. Are we looking for metal lathe projects, CNC machining titanium, large CNC machining, brass CNC machining, and 5 axis CNC machining services? We can help you with this!

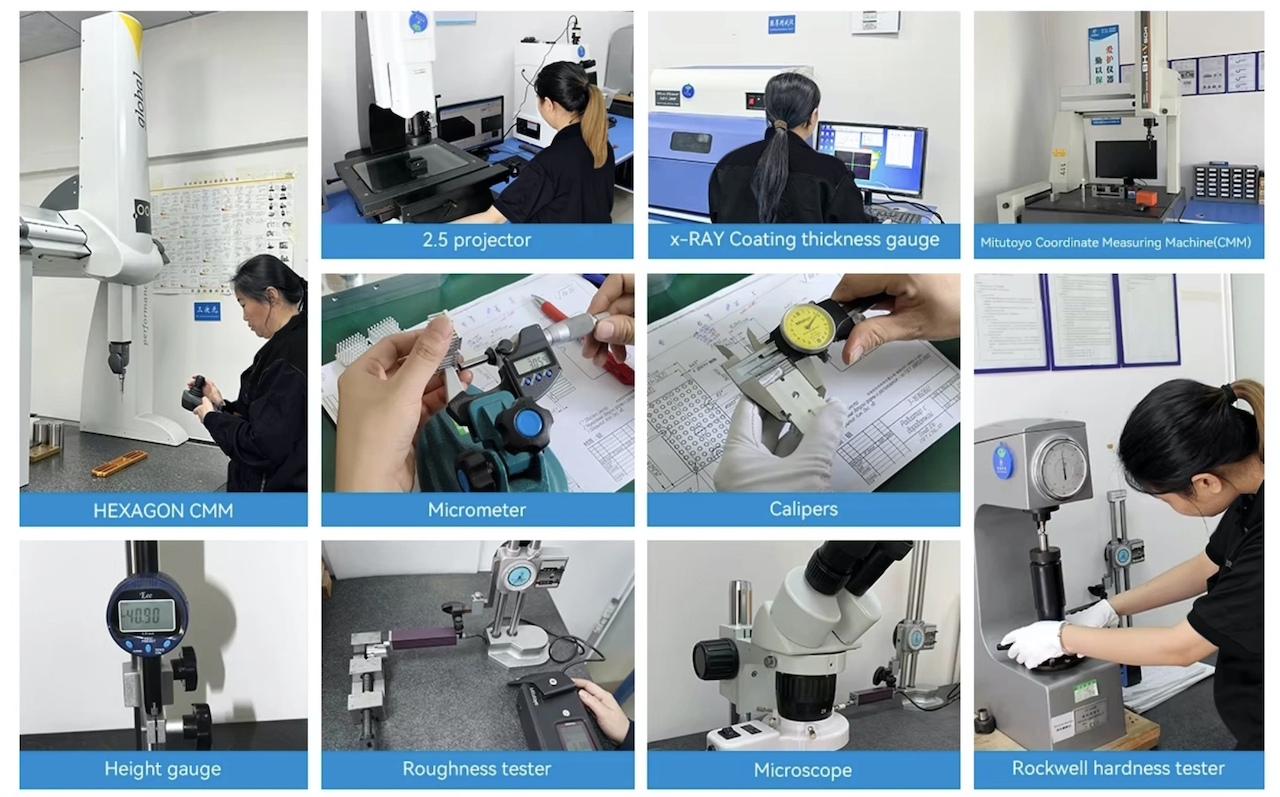

Quality Control on Every Single Part

TEAM RAPID takes quality seriously —we guarantee every part we makes goes through rigorous quality control to ensure it meets your exact specifications.Weather for mass production or prototypes and low-volume manufacturing, we inspect each component for:

- Dimensional accuracy– verified using precision measuring tools

- Surface finish– ensuring smooth, defect-free surfaces

- Material integrity– checking strength, consistency, and correct grade

- Functional testing– confirming fit, assembly, and performance

Our commitment to quality means you receive reliable, high-performance parts every time, whether your project involvesCNC machining, welding, assembly or special packing. With TEAM RAPID, there’s no compromise — every single part counts.

Start From CNC Prototyping to Mass Production

TEAM Rapid offers one-stop CNC precision machining; we understand the value of accurate prototype CNC machining. We are a CNC machining parts manufacturer in China; we love small-batch CNC machining and can process mass production! For every project, our engineer will discuss each part with you and seek to offer the highest degree of accuracy at the lowest CNC machining price possible. We are always glad to support you in successfully launching your products to market.

Programming CNC Prototyping Low Volume Manufacturing Mass Production

Frequently Asked Questions

What is CNC Machining?

CNC machining is a type of metal fabrication that involves the use of written code to control the machinery to process. It is commonly used in the manufacturing of various components. The code used in CNC machining determines various parameters of the process, such as the cutting head's movement and the part's RPMs.

A subtractive fabrication technique is used by CNC machining services. This method involves the removal of material from the production process, which is different from additive manufacturing(3D Printing).

How Much does CNC Machining Cost Per Hour?

The cost of a CNC machining operation can vary depending on its complexity and the materials used. Depending on the complexity of the project, a CNC machining operation can cost from 30 RMB to 120+ RMB an hour. However, complex projects can be more costly.

How to Calculate CNC Machining Cost Per Hour?

One of the most common ways to estimate the cost of CNC machining is by taking into account the hours worked.Then, multiply the annual salary by the number of hours the worker works. Depending on the type of machine used, the cost of CNC machining can vary. For instance, a 5-axis machine costs more than a 3-axis model.

How to Design Parts for CNC Machining?

There are many factors needed to take into consideration for designing a CNC part, such as:

1. Types of materials that can be used in CNC machining.

2. The right CNC machine is suitable for the part.

3. Whether the product's shape can be machined by CNC without undercuts.

4. How the final product will be used(e.g.strength requirements)

5. How many operations and processes might need.

6. Common tool sizes and whether bespoke tools are needed

These factors can help determine the design of a CNC machined part. Also,

engineers and designers can consider reducing the cost of machining by reducing the required time based on these factors. Optimizing just one aspect of the process can only achieve not too much in reducing the cost and time involved in manufacturing a part.

What is CNC Machining Technology?

Computer-controlled machining (CNC) is a process utilized in the manufacturing industry to control various machine tools, such as routers, lathes, and grinders. This guide will teach you more about this process. Before you start implementing the procedures of CNC, it is important that you thoroughly understand the various features of this process.The term CNC refers to precision machining, and this process has affected almost every vertical industry. Below is a timeline of the evolution that occurred in the history of CNC machining.

1952 – 1958

During the Cold War, the need for improved productivity and efficiency in the production of various weapons and machines became more prevalent. In 1952, Richard Kegg and MIT developed the first CNC milling machine, which was known as the Cincinnati Milacron Hydrotell. In 1958, Kegg would also patent a device that controls a positioning machine.

1967 – 1972

The development of computer-aided design and machining technologies in 1972 led to the increasing recognition of CNC machining worldwide. Although the inclusion of CAM and CAD in CNC machining led to numerous advancements, they were not widely used in the manufacturing industry.

1976 -1989

In 1976, 3D models and computer-aided design were added to the list of capabilities of CNC machines. In 1989, the use of software-controlled models became the industry standard.

Today's CNC Industry

The evolution of a CNC machine is not easy to explain. From a simple machine that was controlled using a punch card, to a software-based machine, it is a bit enigmatic. The evolution of CNC machines has led to faster and more accurate machining.