5-Axis CNC Precision Machining Services

TEAM Rapid applies the 5-axis CNC machining configuration in rapid prototyping, and the following mass production. The traditional 3-axis equipments are still be usable for today's manufacturing projects. But, the 5-axis configuration can offer precision machining services even for complex parts manufacturing.

Advantages of 5-axis CNC precision machining services

Boost Efficiency and Production Time.

With the 5-axis CNC, five different CNC cutting tools are working together. This equipment can help improve the overall efficiency of your manufacturing production. It will remove all unnecessary processes and waiting time. It results in the improvement of your overall production time, allowing speedier manufacturing.

Boost Precision and Accuracy.

With more cutting tools you can work with, the precision and accuracy of each cut will increase. You can work on trimming and cutting more areas around the material workpiece. You can apply small cutting details with the 5-axis CNC equipment. It makes working on a complex prototype or product design possible. Also, it brings you the highest accuracy.

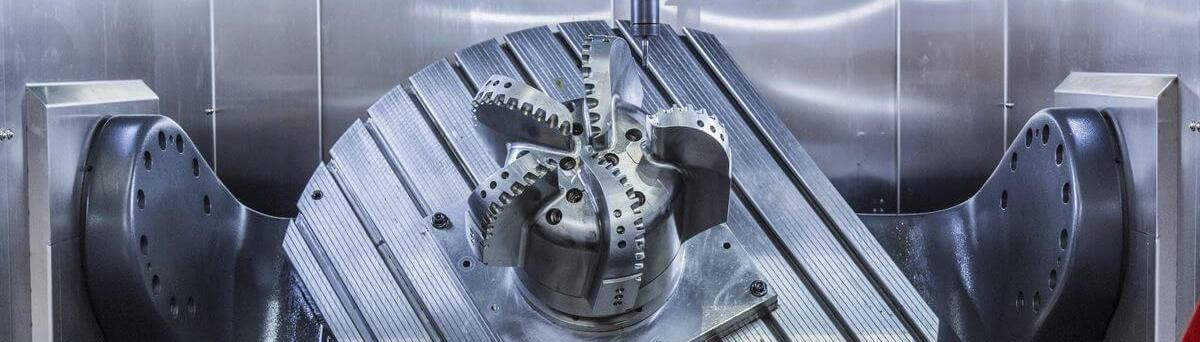

Production of Complex Geometry by Precision Machining Services.

The regular CNC equipment has some restrictions regarding complex geometry production. However, the 5-axis CNC configuration makes adding complex geometries to your design more feasible. The 5-axis cutting tools can go to nook-and-cranny to follow your complex geometric design. You can add more features to the final parts, thanks to the 5-axis CNC configuration.

Reduce Tool Wear and Replacement.

The 5-axis CNC configuration allows each tool to work more lightly while achieving better efficiency. There will be less stress applied on each axis during the rapid manufacturing process. The 5-axis configuration can reduce tool wear, allowing you to use each cutting tool longer. It will also mean that you will minimize the instances of replacing each tool in your production.

Have More Polished Surface Finish by Precision Machining Services.

You can work on cutting more details on the material workpiece with the 5-axis CNC. This cutting process will get you a better surface finish for the complete parts you produce. It results in better overall aesthetics for the parts without additional finishing processes. It will make surface finishing optional for you.

A Wider Coverage for the Workpiece Material.

The 5-axis configuration can also cover more areas around the workpiece material. The extra coverage area allows you to create bigger-sized parts for your project. Also, it will let you reach the previously unreached area. You can sculpt more shapes in intricate areas.

The Manufacturing Process - 5 Axis Precision Machining Services

The 5-axis CNC equipment will undergo the same manufacturing process as the regular 3-axis configuration. However, there are some upgraded aspects of the manufacturing process that you need to know. These upgraded aspects will allow you to produce better and more scalable components. Here are some aspects of the 5-axis CNC machining process:

Linear and Rotational Axes.

The 5-axis CNC system uses additional rotational axes for its operation. The two rotational axes will go hand-in-hand with the regular three linear axes. It makes it easier to access specific areas of the material workpiece.

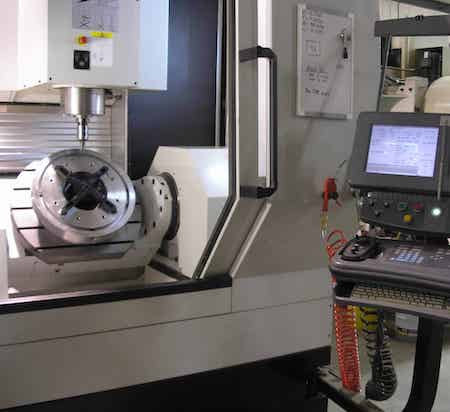

Computer-Assisted Process.

You will still need to connect the 5-axis CNC equipment to the computer mainframe for it to work. All manufacturing processes are programmable via computer. You can set various configurations of the 5-axis CNC equipment via the computer command center.

From CAD to CNC Instructions.

The 5-axis CNC works the same way as the traditional 3-axis system. It uses the CAD software file to turn into the CNC instructions. You will need to prepare the design blueprint in the CAD format before you can turn it into programmable CNC instructions. It will give you the precise manufacturing steps to create the final parts based on the blueprint design.

Completely Automatic.

You can use the 5-axis CNC configuration in conjunction with the robotics technology. You can run the manufacturing production with complete automation. It ensures that everything will go precisely according to your production schedule. Moreover, you can also get complete accuracy for each cut you apply on the material workpiece.

Linear and Rotational Control.

CNC equipment with the 5-axis configuration allows control for both the linear and rotational axes. The three linear axes allow control for the spatial direction, whereas the two rotational axes allow control for the rotational direction. These axis combinations allow for a better reach around the material workpiece. It also allows for more flexible cutting techniques.

Speed and Movement Control in Precision Machining Services.

You can also control the speed and movement of the five axes in your CNC equipment. It will allow for more precise cuts on each axis. It gives the best configuration for different material workpieces, allowing smoother cutting.

From Small to More Sizable Parts.

The 5-axis CNC configuration allows you to scale your project's requirements. You can make smaller or more sizable parts for your production with the 5-axis CNC equipment. It provides you with more flexibility to produce components for more industrial applications.

Precision Machining Services - Industrial Applications

Energy Industry.

The 5-axis CNC system is valuable for creating various equipment in energy production facilities. It includes creating wind turbines for wind-based energy production.

Medical Devices Made By Precision Machining Services.

You can produce various medical-related items for hospitals and surgical operations. The 5-axis CNC can create precise medical parts based on custom requirements. You can also ensure the part's safety for the surgical operations.

Aerospace.

The scalability of the 5-axis CNC configuration allows you to create more sizable components in more industries, such as aerospace. You can produce precise aerospace components with the 5-axis CNC equipment. It covers both the exterior and interior design in the aerospace industry.

Automotive Parts Made Via Precision Machining Services.

You can use the 5-axis CNC to produce the engine, gears, and vehicle body parts. You can also create polished components for the vehicle, thanks to the precision machining. Most vehicle manufacturers today use the 5-axis CNC system in their vehicle production.

Jewelry.

Today's jewelry designs are becoming more intricate. The 5-axis CNC system can be usable for cutting intricate jewelry designs using its precision machining. This way, you can get plenty of uniquely designed jewelry with complex geometrical shapes.

5-Axis CNC Tolerances In Precision Machining Services

You can handle tighter tolerances when using the 5-axis CNC precision machining. The tighter tolerances it can handle make the 5-axis CNC even more capable of cutting down the material workpiece to its tiniest details. For the 5-axis CNC system, the tolerances range from 5% to 10% on most materials.

Depending on the material workpiece, you can set the tolerances from 0.05 to 0.10 from the material's default tolerance. The 5-axis configuration system allows you to set tighter tolerances to achieve more contoured cuts on the complex geometric design.

Factors that affect precision tolerances

CNC Equipment.

Higher-end CNC equipment can handle tighter tolerances better. There are also more configuration options to help customize the precision tolerance factor. It will allow you to perform tiny cuts on the material workpiece based on your programmed commands.

Cutting Tools.

The quality of each cutting tool you use will also affect the precision tolerance in your production. The "dull" cutting tools on the 5-axis CNC might not cut at proper precision tolerance if you don't replace them first. Some workpiece materials also need specialized cutting tools for the best precision tolerance.

Workpiece Material.

Different workpiece materials will offer different precision tolerances. Steel's tolerances will differ from wood. So, you can't just generalize their tolerances. Your workpiece material will affect how accurate your cuts will be.

5-Axis Machining vs. Traditional CNC Machining

What can you expect from the 5-axis machining compared to the traditional CNC?

An Advanced Machining Configuration.

Unlike traditional CNC machining, 5-axis machining offers an advanced machining configuration with more options and features you can use. You can set and configure every aspect of the machining process from start to finish. It makes producing custom components much easier and more precise.

Improvements in Programming and Computerization.

The 5-axis CNC system has a much more complex programming and computerization system than the traditional CNC. You can assign more tasks to the 5-axis CNC equipment and complete the tasks with better efficiency. The improvements in programming and computerization will also make it easier to control more components and complete more complex tasks.

Upgraded Level of Accuracy and Precision.

Traditional CNC machining can give you excellent accuracy and precision for each cut. However, the 5-axis configuration provides even more accuracy and precision because of its movement flexibility and outreach. Its upgraded accuracy and precision give you more accurate features for the smaller components you produce.

CNC Machining for More Sizable Parts.

Traditional CNC has a size restriction for the material workpiece you can work on. However, the 5-axis system gives you fewer restrictions on material size. You can use it to machine more sizable components, such as in the airplane and automotive industries.

Precision Machining Services: Price Range for 5-Axis Machined Workpieces

The 5-axis configuration system has a price range of $100,000 to $1.5 million for the equipment. It will depend on various factors, such as machine complexity, features, accessory compatibility, and capacity. The more popular the brand, the price of the 5-axis equipment will also become much more expensive.

The machined workpieces for the 5-axis CNC will also have various prices. It will depend on the material type, machining service fees, design complexity, and production time. In CNC machining production, you need to pay hourly machining service fees. The price range can fall between $30 to $150 per hour for the 5-axis machining process. It excludes the price of material workpieces and other related fees.

Contact Us

Manufacturing with the 5-axis CNC equipment is becoming the norm in today's manufacturing industry. It offers more efficiency and speed compared to the regular 3-axis system. Furthermore, its flexibility and scalability allow you to use the 5-axis CNC system in more industrial applications. Contact us today!