Zinc Die Casting - NO Minimal Order Quantity

Compared to the other casting materials, zinc is perhaps the most accessible and versatile metal you can use in the die casting process. Zinc alloy has good properties not only in toughness but also the high impact strength. With zinc die casting, you can create various metal parts and components with certain finishing qualities and particular mechanical and physical characteristics.

Since zinc alloy for die casting parts performs much better than any other sand-casting metal parts in toughness and impact strength at average temperature, the parts are widely used in many industries. As one of the best alternatives to aluminum, manufacturers use zinc die cast to produce certain metal parts, prototypes, and components for various applications. However, the most common use of zinc die casting is in the automotive industry.

Zinc Casting Applications

You can find many parts and components in the automotive industry that use zinc alloy die casting in their production processes, such as vehicle brakes, engines, air conditioner components, and many others.

● Engines

Zinc has excellent thermal and electrical conductivity, which is why zinc alloy die casting parts manufacturers use zinc alloy casting to produce parts of vehicle engines in the automotive industry. It is durable and will last for a long time.

● Air Conditioning Parts

Some parts of air conditioning systems in various vehicles use high-pressure zinc die casting in their production process. Zinc is an excellent material for creating small parts and components for the vehicle’s air conditioning system.

● Fuel Systems

The good electrical and thermal conductivity also makes zinc suitable for the vehicle’s fuel systems. Many components used in the vehicle’s fuel systems are produced in zinc under a zinc die-casting plant.

● Chassis Hardware Parts

The durability of zinc materials makes it suitable for chassis hardware parts production. Zinc die cast is the primary method to produce various chassis hardware parts in vehicles.

● Brakes and Power Steering

The durability of zinc materials is also helpful for producing parts and components for the brakes and power steering in vehicles. It will ensure long-lasting use of the vehicle’s brakes and steering mechanisms.

Zinc Die Casting Applications – Expanded List

| Industry | Example Parts / Components | Key Benefits of Zinc Die Casting |

|---|---|---|

| Automotive | Door handles, locks, hinges, engine brackets, sensor housings, gearbox housings, suspension components, battery brackets, steering column parts, mirror housings, window regulator gears, HVAC brackets | High strength, precision, corrosion resistance, ability to produce complex shapes, lightweight |

| Consumer Electronics | Electronic enclosures, smartphone mid-frames, laptop hinges, EMI/RFI shielding housings, switchgear components, camera mounts, audio frames, smart home device housings, wearable device housings | Dimensional accuracy, EMI shielding, thermal stability, lightweight, easy plating or finishing |

| Industrial & Machinery | Machine brackets, valve bodies, pump components, gear housings, control panel housings, conveyor parts, actuator housings, motor brackets, instrumentation housings, compressor components | Mechanical strength, corrosion resistance, precision, durability under stress |

| Hardware & Architectural | Locks, knobs, handles, hinges, cabinet hardware, decorative fittings, door/window fittings, gate and railing brackets, shelf supports | Decorative finishing options, corrosion resistance, durability, high dimensional accuracy |

| Lighting | Fixture housings, mounting brackets, reflectors, heat sinks for LEDs, outdoor lamps, track lighting components, recessed lighting frames | Thermal conductivity, precision, lightweight, corrosion resistance, supports complex designs |

| Plumbing & Sanitary | Valve bodies, pipe fittings, shower heads, faucets, drains, tap handles, bathroom accessory brackets, water meter housings, plumbing connectors | Corrosion resistance, smooth surface finish, dimensional accuracy, durability in wet environments |

| Medical & Dental | Diagnostic device housings, dental instruments (clamps, forceps), surgical instrument components, laboratory equipment brackets, medical device casings, orthopedic tool components | Precision, lightweight, corrosion resistance, durable under repeated use |

| Defense & Security | Optical instrument housings, electronic housings, small-caliber ammunition casings, weapon mounting brackets, surveillance camera housings, tactical equipment components, communication device enclosures | Strength, precision, lightweight, dimensional stability, durable in harsh conditions |

| Sustainable & Recyclable | Recycled automotive brackets, furniture and hardware components, eco-friendly consumer electronics housings, energy-efficient cast parts | Fully recyclable, low melting point for energy-efficient production, supports sustainable manufacturing |

What Is Zinc Die Cast and How It Works

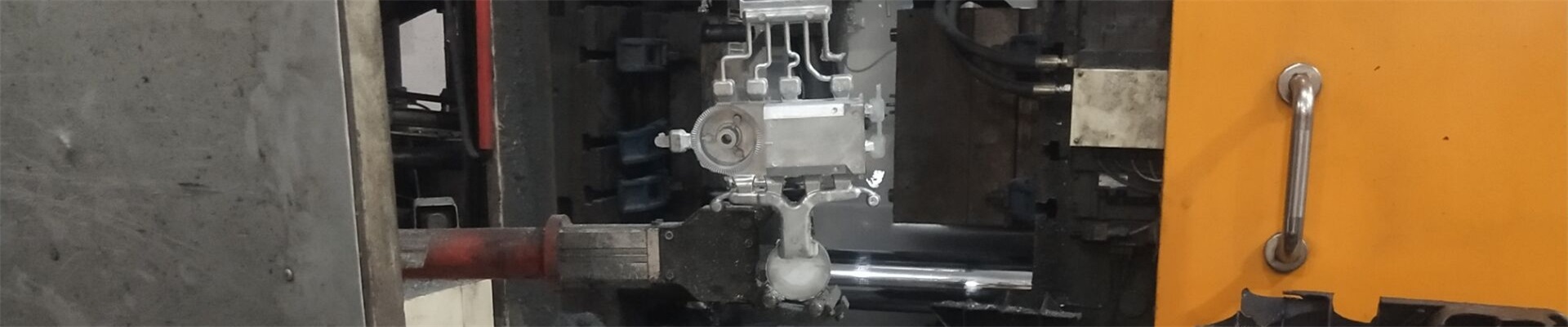

Zinc alloy casting works the same way as the die casting method with other metals. However, with the low melting point of zinc materials, the die casting process can go faster than with other metals. First, you will need to prepare the zinc alloy die casting mold to produce the parts or components. The Zamak die-casting mold will have two pieces clamped together using the high-pressure mechanical system.

Next, you will need to melt the zinc materials and insert the melted zinc into the mold cavities. The melted zinc will solidify, following the hollow shapes of the mold cavities. Once it thickens, you can pull out the resulting metal parts or components from the clamped mold shell and use it for other production processes.

Why Zinc Casting: The Characteristics of Zinc Alloy for Die Casting

Zinc materials have specific characteristics that make them suitable for die casting. With the unique attributes of zinc materials, manufacturers can produce high-quality hardware parts and components for various purposes.

● Stability

Zinc has a material stability that allows you to produce zinc parts and components that are sturdy and durable.

● Thermal Conductivity

Zinc is an excellent material that can withstand high operating temperatures, allowing you to create parts that need to get exposed to constant heat.

● Electrical Conductivity

It is also typical for manufacturers of zinc alloy die casting parts to use zinc to produce various electrical components, as it has excellent electrical conductivity.

● Low Melting Point

Zinc materials have a low melting point, so casting is easy and allows you to produce parts at a faster production rate.

● Electroplating

The zinc die casting plant can apply electroplating on die-cast zinc materials, making it more conductive to electricity. It is perfect for mechanical components that require constant electric currents.

● Complex Geometries

The zinc die casting companies can also use zinc to create complex geometries, allowing you to produce parts and components with complex design requirements.

Zinc Die Casting vs. Aluminum Die Casting

Zinc and aluminum are the two most commonly used alloys in die casting, but they serve different needs. Understanding how they compare helps engineers and buyers choose the right material for performance, cost, and production efficiency.

1. Material Characteristics

1. Material Characteristics

Zinc Alloys:

-

Higher density and heavier feel

-

Excellent ductility for small, thin-walled parts

-

Very good impact strength

-

Exceptional dimensional stability

Aluminum Alloys:

-

Lightweight and ideal for reducing product weight

-

Higher strength-to-weight ratio

-

Better performance at elevated temperatures

-

Naturally corrosion-resistant surface

Summary:

Zinc is ideal for compact, detailed parts. Aluminum is preferred when low weight and structural strength are required.2. Casting Performance

Zinc Die Casting:

-

Melts at a lower temperature, enabling fast cycles

-

Outstanding fluidity for thin walls and fine detail

-

Minimal porosity and excellent surface finish

-

Hot-chamber process reduces production time

Aluminum Die Casting:

-

Higher melting temperature means slightly longer cycle time

-

Requires thicker wall design for best stability

-

Can cast larger components more easily

-

Cold-chamber machines create higher injection force and good strength

Summary:

Zinc delivers higher precision and better surface quality. Aluminum supports larger and more structural components.3. Tooling Life and Manufacturing Cost

Zinc:

-

Low melting temperature extends die life significantly

-

Less wear on tooling, reducing maintenance and long-term cost

-

More cost-effective for high-volume production of small parts

Aluminum:

-

Higher melting temperature causes faster mold fatigue

-

Shorter die life compared to zinc tools

-

More economical for medium to large components where weight matters

Summary:

Zinc is the more economical choice for long-run production, while aluminum becomes competitive for bigger, lightweight applications.4. Surface Finish and Post-Processing

Zinc Parts:

-

Very smooth as-cast surface

-

Excellent for electroplating, painting, and decorative finishing

-

Minimal machining required

Aluminum Parts:

-

Rougher as-cast finish

-

Often requires polishing or machining

-

Accepts powder coating, painting, and anodizing

Summary:

For cosmetic parts or products requiring premium finishing, zinc offers superior results.5. Best Application Fit

| Choose Zinc Die Casting When You Need: | Choose Aluminum Die Casting When You Need: |

|---|---|

| Small or medium parts with fine details | Lightweight parts for automotive or electronics |

| Tight tolerances and high dimensional accuracy | Good thermal performance or heat dissipation |

| High-volume production with long tool life | Structural strength in larger components |

| Smooth surfaces for plating or decorative finish | Natural corrosion resistance without plating |

Which One Should You Choose

-

Zinc die casting is the best choice for precision components, thin-walled designs, consumer products, hardware, connectors, and decorative parts.

-

Aluminum die casting is ideal for larger housings, automotive components, structural brackets, and parts requiring good heat conductivity.

Both materials perform exceptionally well — the right choice depends on size, weight, finish, production volume, and function. If you are unsure which alloy fits your design, our engineering team at TEAM RAPID can evaluate your drawings and recommend the best and most cost-effective solution.

Zinc die casting is the best choice for precision components, thin-walled designs, consumer products, hardware, connectors, and decorative parts.

Aluminum die casting is ideal for larger housings, automotive components, structural brackets, and parts requiring good heat conductivity.

Zinc Die Casting Alloys at TEAM Rapid

Zinc alloy die casting is one of the core services at TEAM Rapid. We offer a series of die-cast zinc alloys to meet the customer's die casting needs. Zinc2, Zinc3, and Zinc5 are the most popular zinc alloy die casting materials these years. The properties and performances of these three brands of zinc are different. Here we have the details:

Zinc 2

It is also known as Zamak 2, which has the highest hardness and strength of zinc alloys.

Zinc 3

We also call Zamak 3, it is the most commonly used zinc alloy at TEAM Rapid, and it has excellent properties in finishing characteristics.

Zinc 5

Name Zamak 5 as well. It has less flexibility than Zinc 3 and higher strength due to the higher copper content. Zinc 5 is commonly used in Europe.

Other Zinc Alloy Available for Pressure Die Casting

| Alloy | Characteristics | Used For |

|---|---|---|

| Zamak 7 | Best fluidity, low Mg, excellent precision | Thin-wall, decorative parts |

| Zamak 8 | Higher Cu → higher strength | Wear-resistant parts |

| ZA-8 | Stronger than Zamak, hot-chamber castable | Small/medium structural parts |

| ZA-12 | High strength, cold-chamber only | Gears, brackets |

| ZA-27 | Very high strength, bearing properties | Heavy-duty parts |

| ACuZinc alloys | Very high strength & toughness | Automotive, high-load components |

| EZAC | Ultra-high strength & creep resistance | Locks, tools, engineered parts |

| ZP5 / ZP8 | Regional equivalents | General die casting |

| Zinc Alloy No. 12 | Legacy alloy | General mechanical parts |

TEAM RAPID: One Of the Best Zinc Die Casting Manufacturers in China

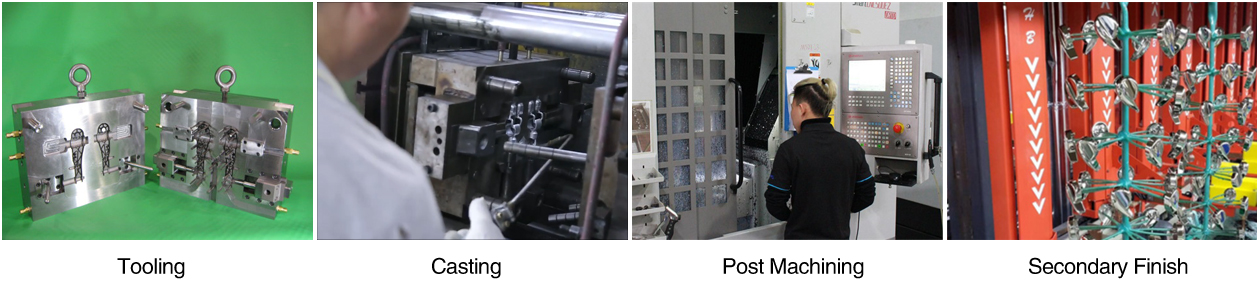

As one of the best zinc alloy die-casting parts manufacturers in China, TEAM RAPID offers one-stop manufacturing services for zinc die-casting. We provide services from engineering to zinc alloy die casting mold making, zinc injection molding, post-machining, and secondary finish. We can offer customers high-quality zinc parts from a few grams to more than 50 pounds with different volumes. We provide low-volume rapid manufacturing zinc parts by casting services as well.

Tooling

Single cavity tooling, multi-cavities tooling, family tooling, etc., zinc alloy die casting mold available. MUD mold base for low-volume zinc casting parts.

Casting

They make zinc casting parts from small clips to huge electronic devices with complex geometries, such as thin walls.

Post Machining

Equipping with advanced CNC machining centers, we can process CNC post-machining on those dimensions with tight tolerances to get specific parts.

Secondary Finishes /Assembly

Powder coating, e-coating, chrome plating, and other bright/matt finishes.

Low-Volume Zinc Die Casting Parts

TEAM RAPID offers aluminum and zinc die casting services for low-volume production needs. We adapt three main methods in low-volume manufacturing to cut down your tooling costs and get high-quality casting parts. These methods are:

MUD Mold Base (Master Unit Die)

MUD mold base, we also call it master unit die, both the aluminum die casting vs. zinc die casting projects can apply the MUD mold base. It is a quick interchangeable modular mold base used in low-volume manufacturing. Two or several casting molds share one MUD mold base to cut costs and shorten the lead time. TEAM Rapid owns the MUD mold base; we create a series of MUD mold bases stored and ready for upcoming projects. They are free and at no charge for use.

Family Mold

As the low-volume demands, we can create a mold with more than one cavity to cover multiple parts of the same materials and have a similar size. We can obtain different zinc alloys for die casting parts in one cycle. Family molding can significantly save not only the tooling cost but also the casting costs. It is commonly used in injection molding and die casting. The part layout is essential!

Interchangeable Inserts

One of our customers wanted to have zinc die casting parts in 3 versions. These three versions are in the same outline but with different knots, but the demanded volume is low. There are 100 units of parts after sample approval. As a professional zinc die casting plant, TEAM RAPID suggests the customer go ahead with the proposal of interchangeable inserts. We built one mold with three sets of different inserts. The geometries of all these inserts are different, and they can be assembled into the mold quickly and easily. We pull down the mold to change the insert after casting one version.

Zinc Parts CNC Prototyping

CNC prototyping is an essential step in product development, allowing designers and engineers to test form, fit, and function before committing to full-scale die casting. Zinc, with its excellent machinability and dimensional stability, is available block material for rapid prototyping.

Contact Us for High-Quality Zinc Die Casting Parts

Looking for precision zinc die casting parts for your project? TEAM RAPID provides custom zinc die casting and finishing services to meet your exact specifications. Whether you needs mall batch manufacture or high-volume production, our experienced engineers will help you optimize your design, select the right zinc alloy, and deliver high-quality parts on time.

Why Choose TEAM RAPID

-

Expertise in Zamak and ZA zinc alloys

-

PrecisionCNC prototyping and die casting

-

Fast turnaround times and competitive pricing

-

Full range of surface finishing options(polishing, plating, powder coating)

-

Dedicated engineering support to ensure your design works perfectly

Get Your Custom Quote Today

Don’t wait to bring your project to life. Contact us now to discuss your zinc die casting requirements, request a quote, or ask any questions about materials, processes, or lead times.

- Call us:+86 0760 88508730

- Email us: [email protected]

- Or fill out our online inquiry form and our team will respond promptly.

Let’s Turn Your Design Into Reality

With TEAM Rapid, you can save cost, improve efficiency, and achieve high-quality results with zinc die casting. Get started today and see why clients worldwide trust us for precision metal parts.

Frequently Asked Questions

Why Use Alloys Instead of Pure Zinc in Pressure Die-casting?

Zinc alloy can have the same performances as pure zinc, but less costs.

Is Die Cast Zinc Safe for Food?

Although certain metal components, such as aluminum, copper, and zinc, are safe for food, they have to be surface treated after casting.

How does Zinc Die Cast Compare With Solid Brass?

Most die-cast hardware is made out of zinc, which has a bluish-white color and is an element that can be found in nature. Zinc is commonly used in the manufacture of various products, such as hygiene products and die-cast hardware. It is cheaper than brass, but it is less durable and lighter.Solid brass, or die cast brass, simply signifies that the object is brass all the way through.

Does Die Cast Zinc Rust?

Yes, zinc is a metal that can rust. It is not a rust inhibitor. but it is an oxidizer.