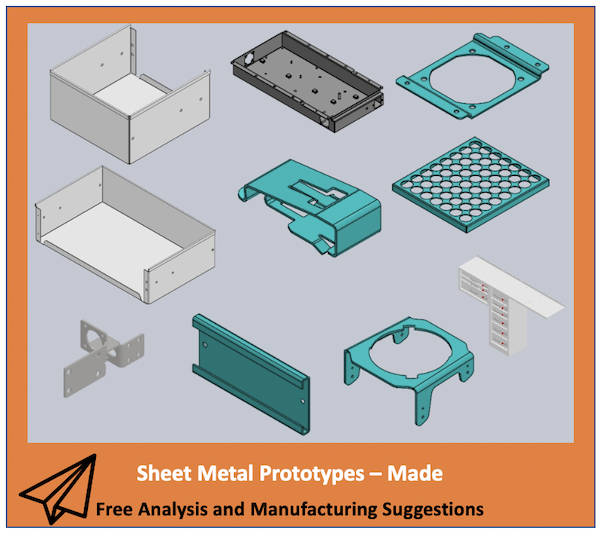

Sheet Metal Prototype - Low Cost, Fast Delivery

What is Sheet Metal Prototyping

Sheet metal prototyping is a manufacturing process that creating early-stage sheet parts or prototypes to test a design before moving into full production. Engineers and product teams can verify form, fit, function, and manufacturability using real metal materials by this method, which can save the costs and lead time.

Sheet Metal Prototyping Methods

Below are the main methods of sheet metal prototyping methods at TEAM RAPID, these are the techniques most manufacturers use to produce fast, low-volume metal prototypes.

-

Laser Cutting

Laser Cutting

A process that uses a focused laser beam to cut shapes from flat sheet metal.

Laser Cutting

Laser Cutting

-

Waterjet Cutting

A cutting method that uses high-pressure water to slice metal without heat.

-

Plasma Cutting

A technique that cuts metal by melting it with a high-temperature plasma arc.

-

CNC Punching

A method that punches holes and features into sheet metal using CNC-controlled tools.

-

Press Brake Bending

A forming process that bends sheet metal into specific angles and shapes.

-

Soft-Tool Stamping

Low-volume forming method that shapes metal by simple or temporary dies.

-

Welding & Assembly

Processes that join multiple sheet metal parts into one complete prototype.

How to Choose

Here we have a comparison table:

Method

Typical Tolerance*

Accuracy

Speed

Tooling

Best Use

Laser cutting

±0.1 mm (±0.004″)

Very high

Very fast

None

Complex 2D shapes

Waterjet cutting

±0.2 mm (±0.008″)

High

Medium

None

Thick / heat-sensitive parts

Plasma cutting

±0.5 mm (±0.020″)

Medium

Fast

None

Large, thick steel parts

CNC punching

±0.1–0.2 mm

High

Very fast

Low

Repetitive features

Press brake bending

±0.5° angle / ±0.3 mm

High

Fast

Low

3D forming

Soft-tool stamping

±0.1–0.2 mm

High

Medium

Medium

Production validation

About TEAM RAPID

TEAM RAPID offers quick and cost-effective custom sheet metal fabrication services. Punching, bending and cutting from standard gauge metal for your designed parts in rapid prototyping and low-volume production runs. We can help you to produce high-quality, durable metal parts with a wide selection of finishes and materials that meet your specifications. Our customers are happy with our services. Contact us today!

Rapid Sheet Metal Materials Available in the Sheet Metal Prototyping

There are various rapid sheet metal materials you can use for sheet metal fabrication; each can offer you certain advantages and disadvantages. Also, each material will be suitable for different applications, meaning that you can pick the right material types according to your project requirements. You also need to ensure that each material meets the quality standards for sheet metal prototypes to provide the best result in your projects.

● Stainless Steel

Stainless steel is a type of steel with quite a lot of chromium content, preventing it from rusting. It's a much better custom sheet metal material than regular steel, but it will also be more expensive. It's pretty easy for you to use this material in your precision sheet metal fabrication, and you can also get more polished surfaces when you use this material.

● Aluminum

One of the best characteristics of aluminum is that it is lightweight to use. Also, aluminum has better electricity and thermal conductivity, which makes it preferable to use if you want to create custom sheet metal electrical components. It will be more expensive than regular steel, but you can use it in a wide range of applications, including for home appliances and other consumer electronics.

● Copper

Sheet metal copper is best to use for creating electrical components. However, you can't do much with copper in the sheet metal process. The best thing you can do with this material is to bend it. You can use this material in various electronic equipment and electrical components.

● Carbon Steel

Carbon steel is a type of steel with a significant amount of carbon. You can get a more robust carbon steel the more it has a carbon component. However, the stronger the carbon steel, the more difficult it will be for you to shape it during the sheet metal prototyping process.

● Brass

Brass combines copper and zinc, giving you a material much more substantial than regular copper. You will often use this material in various custom sheets of metal hardware components, such as nuts and bolts.

● Steel

Regular steel is the most common sheet metal prototype material in your rapid manufacturing process. It is affordable, and you can work with it to shape various objects and prototypes. However, regular steel is susceptible to corrosion in long-term usage.

Rapid Sheet Metal Material Comparison

Material

Key Properties

Advantages

Disadvantages

Common Applications

Material Cost

Manufacturability

Stainless Steel

Steel with high chromium content; corrosion-resistant

High precision, polished surfaces, rust-resistant

More expensive than regular steel

Precision sheet metal parts, medical components, polished enclosures

High

Moderate – harder to cut and form than carbon steel; welding requires skill

Aluminum

Lightweight; good thermal & electrical conductivity

Easy to handle, versatile, corrosion-resistant

Higher cost than regular steel

Electrical components, home appliances, consumer electronics

Medium–High

High – excellent formability, easy bending, moderate welding difficulty

Copper

Excellent electrical & thermal conductivity; ductile

Ideal for bending, electrical conductivity

Limited forming options; difficult to shape

Electrical components, electronic equipment, conductive parts

High

Low–Moderate – easy to bend, but cutting and complex forming are challenging

Carbon Steel

Steel with high carbon content; strong and robust

Very strong, durable

Harder to shape as carbon content increases

Structural prototypes, mechanical components requiring strength

Low–Medium

Moderate – low-carbon grades easy to form and weld; high-carbon grades are harder

Brass

Alloy of copper and zinc; stronger than copper

Good strength, corrosion-resistant, attractive finish

More expensive than copper

Hardware components, nuts, bolts, decorative metal parts

High

Moderate – easy to bend, moderate difficulty in cutting and welding

Steel (Regular)

Standard carbon steel; widely available

Affordable, easy to shape

Susceptible to corrosion over time

General-purpose prototypes, enclosures, basic structural parts

Low

High – easy to cut, form, and weld; very common in prototyping

As a professional sheet metal shop, TEAM RAPID offers a series of rapid sheet metal materials for your selection. You can easily have your precision sheet metal fabrication parts here!

Benefits of Making Sheet Metal Prototypes

Sheet metal prototyping can provide you with various advantages in your manufacturing process. Each prototype sheet metal is suitable for a wide range of applications, depending on the project you need to complete. For instance, for creating prototypes of electrical components, copper and aluminium materials might be the best ones you can use.

● Easier to Work with

● Easier to Work with

There is various prototype sheet metal you can use in the prototyping process. Compared with plastics, metals can be easier to work with. You will also get a much better build quality when you work with metal prototypes instead of plastics.

● Avoiding Errors in Large-scale Manufacturing

Before you put them into mass production, you can use sheet metal prototypes to test the various aspects of your products, such as their features. Thus, it can help you avoid any errors in the large-scale manufacturing of your products.

● Cost-effectiveness

Some sheet metal prices can cost more than other materials. However, you can also use cheap metal materials, such as steel. You can save a lot of money in the long run by producing sheet metal parts from steel.

● Compatibility with 3D CAD Design Software

You can also rely on more precise and accurate cuts when using metal materials. Also, sheet metal prototypes will have smoother and better overall finishing, which is excellent for you to fit them with other hardware components.

● More Precise and Accurate Cuts in Prototype Sheet Metal

You can also rely on more precise and accurate cuts when using metal materials. Also, sheet metal prototype will have smoother and better overall finishing, which is great for you to fit them with other hardware components.

Sheet Metal Prototyping Fabrication at TEAM RAPID

| Place of Origin | Zhongshan City, Guangdong Province, China |

| Processing | Sheet metal process such as stamping, bending, laser cutting, forming etc. |

| Working Flows | Inquiry - Quotation - Order - Sheet Metal Prototypes Making - Inspection - Packing - Delivery - After Sales |

| Drawing Format | STEP, IGS, DWG |

| Inquiry | Offer the drawings, and tell us your demanded quantity, materials and finishes. |

| Quotation | Typically, within 24 hours |

| Available Material |

Stainless steel, Aluminum, Brass, Copper, Steel etc. |

| Available Wall Thickness | 0.1mm - 8mm |

| Surface Treatment |

Electroplating, Galvanizing, Polishing, Sandblasting, Anodizing, Silk Printing, Laser Engraving, Brushing, Blackening etc. |

| Tolerance | Down to +/-0.05 mm, full inspection before shipment. |

| Size | Custom size according to your drawings. |

| Color | Nearly all the colors in Pantone and Ral books available. |

| Delivery Time | 3 - 20 Days depends on the quantity and part structure. |

| Packing | By carton or according to your requirements. |

| Shipping Methods | Express, by air, by boat etc. |

Are you interested in our precision sheet metal fabrication services? Email us at [email protected] today to learn more about metal rapid prototyping now!

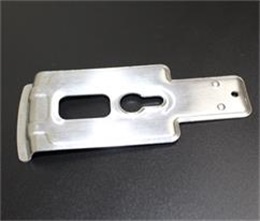

Case Study

One of a USA customers who specializes in kitchen products innovation, they had an idea of new design water tray, and wanted to start from prototype. There are several components in this water tray, the prototype including processes of cutting, bending, extrusion, and welding. Even though the procedure is complicated, TEAM RAPID is happy to help with the customer:

Processes in the Part:

Happy Customer:

Got the parts. We have some more testing but so far they look very good. Nice job Walle and TEAM RAPID!!

Looking great so far!! These will all have the passivation right? And the tray won't have any water leak? I hope to get a quotation for production volume on qty 100, 300, 500, 2000.

Operations and Manufacturing Engineering Manager

Sheet Metal Fabrication — From Prototype to Mass Production

Sheet metal fabrication can be used for making prototypes, but also it can be applied in high-output manufacturing. TEAM RAPID treats prototyping and mass production as a connected process, serving from single part to high-volume. This approach ensures that what works in the prototype stage can be produced reliably, efficiently, and economically at scale.

Early-Stage Prototyping: Designing with Production in Mind

Speed and flexibility matter are the most factors at the prototype stage. Sheet metal prototyping allows engineers to physically evaluate design intent, assembly logic, and real-world performance before finalizing specifications. Unlike digital simulations alone, fabricated prototypes reveal practical issues such as bend interference, fastening access, tolerance stack-ups, and structural rigidity.

Our prototyping process emphasizes:

- Minimal tooling to reduce upfront cost

- Fast iteration for design refinement

- Real manufacturing methods rather than simplified mock-ups

By using production-capable fabrication techniques from the beginning, prototype data remains relevant when the project moves forward.

Design Refinement Through Iteration

Design adjustments often base on the prototype test— hole placement changes, bend angle corrections, thickness optimization, or material substitutions.Every adjustment improves manufacturability while preserving the part’s function and appearance, it bridges the gap between design freedom and production reality.

Prototype feedback often leads to design adjustments — hole placement changes, bend angle corrections, thickness optimization, or material substitutions. Each iteration improves manufacturability while preserving the part’s function and appearance.Unit cost, lead time, and quality consistency later in mass production are affected by decisions made here.

Transitioning from Prototype to Production

Scaling a sheet metal part is not simply a matter of increasing quantity. Production readiness requires:

- Stable material sourcing

- Consistent forming and cutting processes

- Repeatable tolerances across batches

Because our production workflows are derived from prototype fabrication, the transition is smooth. Tooling strategies, process sequences, and inspection criteria are refined rather than reinvented, reducing risk when volumes increase.

Mass Production: Consistency at Scale

Consistency is priority in mass production.Process control replaces flexibility, and every step is optimized for efficiency and repeatability. Our production sheet metal fabrication focuses on:

- Uniform part geometry across large quantities

- Controlled dimensional variation

- Predictable lead times and output capacity

This ensures that every part delivered matches the approved prototype in form, fit, and function — even as production volumes grow.

A Single Manufacturing Partner from Start to Finish

Working with TEAM RAPID from prototype through mass production eliminates communication gaps, redesign delays, and process mismatches. Knowledge gained during early fabrication is carried forward, saving time and preventing costly errors during scale-up. Whether you need a single prototype, a pilot run, or full production quantities, our sheet metal fabrication process is structured to support your product’s entire lifecycle. Contact us today!

Frequently Asked Questions

Why do I Need Sheet Metal Prototypes?

Regardless of your level of experience, working with a skilled and experienced sheet metal prototype company is essential. A prototype allows you to visualize and test the parts before they go into production; it can help you to shoot down potential issues in advance.

What are Your Sheet Metal Price Ranges?

The custom sheet metal fabrication price depends on many factors, such as complexity of prototype sheet metal, budget, and services. Some of these factors can also vary depending on the project's requirements.

How to Quickly Make Sheet Metal Mock Up Prototype Parts?

1.Get ready of your design, the CAD file can be provided instantly.

3D modeling and design software helps engineers create sheet metal prototypes faster by providing them with full visibility into their parts. The CAD file is good for manufacturers to quote and action.

2.Choose in-stock materials.

If the custom prototypes have no special material requirements, you can save quite some time by choose the aluminum, steel, stainless steel, and galvanized steel we have on our shelf and ready to go.

3.Simplify the design, use mechanical fastening instead of welding.

Although welding is a more common solution when it comes to designing sheet metal components, mechanical fasteners are the preferred choice if lead time is a concern. Since welding requires highly skilled technicians, it can take a lot of time to perform in-depth inspection procedures. If you need to quickly assemble a sheet metal prototype, use nuts, screws, rivnuts, and other hardware to add strength and speed up the process.

4.Forego material finishing.

Oftentimes, finishing and post-processing operations add to lead times. Here are some ways to minimize these services. For instance, if your part requires corrosion-resistance, we suggest using stainless steel or galvanized material instead of zinc plating. This process can save you around three to five days. For demo parts, we suggest avoiding finishing altogether.

What is Sheet Metal Prototyping?

Sheet metal prototyping is the process of making prototypes using sheet metals. A sheet metal prototype is a design that allows you to create a working model of a product that will eventually be used. It can also help you test a concept and identify potential flaws before it gets into production. Bending, stamping, forming, laser cutting, etc., are commonly used in sheet metal prototyping. Nearly all the materials available for sheet metal fabrications are OK for sheet metal prototyping.

When is It Appropriate to Use Sheet Metal Prototypes?

1. The custom parts needed in prototype sheet metals.

2. The manufacturing costs of sheet metal fabrication are much more competitive.

3. Need sheet metal prototypes to verify and test the design.

4. There is no tight tolerance for this sheet metal prototype.