Aluminum Die Casting - Leading Aluminum Die Casting Manufacturer

Aluminum die casting is a proven manufacturing process that has been used for decades across a wide range of industries. It enables manufacturers to create lightweight yet durable metal components, making it an ideal choice to produce aluminum die casting products in high-performance. This pressure die casting process is widely applied in consumer electronics, automotive components, aerospace structures, networking devices, and home appliances, where a balance of strength, precision, and weight reduction is essential.

TEAM RAPID has decades of experience producing various types of aluminum die casting parts, we made a series of parts in different industries these years:

| Industry / Application | Typical Aluminum Die Cast Parts |

|---|---|

| Automotive | Engine blocks, cylinder heads, transmission cases, gearboxes, structural brackets, suspension parts, wheels, heat sinks |

| Aerospace | Aircraft structural components, airframe brackets, landing gear parts, actuator housings, ducts, avionics housings |

| Consumer Electronics | Laptop and tablet housings, smartphone frames, heat sinks, audio components, camera and drone parts |

| Networking & Telecommunications | Router and switch housings, antennas, server chassis, optical/electrical connectors |

| Home Appliances | Washing machine and dryer parts, refrigerator housings, AC components, microwave/oven parts, fan frames |

| Industrial Machinery | Pump housings, compressor parts, valve bodies, gearboxes, motor housings, tooling components |

| Lighting & Electrical Equipment | LED housings, street lamps, electrical junction boxes, switches, socket housings |

| Miscellaneous | Sporting equipment parts (bike components, golf club heads), furniture hardware, security/lock housings, robotics components |

Why Choose Aluminum for Pressure Die Casting

Aluminum is one of the most popular metals for pressure die casting due to its unique combination of light weight, strength, and versatility. Using aluminum in die casting offers several advantages that make it ideal for modern manufacturing applications across automotive, aerospace, electronics, and industrial sectors.

Key Reasons to Choose Aluminum:

-

Lightweight Yet Strong

Aluminum has a low density (~2.7 g/cm?) but maintains excellent strength and structural integrity. This helps reduce overall product weight without compromising durability, which is especially important in automotive and aerospace applications.

-

Excellent Corrosion Resistance

Aluminum naturally forms a protective oxide layer that resists corrosion, even in harsh environmental conditions. This reduces maintenance costs and extends the service life of components.

-

High Thermal and Electrical Conductivity

Aluminum efficiently conducts heat and electricity, making it ideal for components like heat sinks, engine parts, and electrical housings. Its thermal properties also allow parts to perform reliably under high temperatures.

-

Design Flexibility

Aluminum pressure die casting enables manufacturers to produce complex geometries with high precision, thin walls, and intricate features. This flexibility allows for lightweight designs and reduced material waste.

-

Cost-Effective and Recyclable

Aluminum is highly recyclable without losing its properties, which lowers production costs and environmental impact. Its ease of casting and machining further contributes to efficiency and scalability.

-

Wide Industry Applications

From consumer electronics and automotive components to aerospace parts and home appliances, aluminum’s combination of strength, precision, and thermal performance makes it a versatile choice for a wide range of applications.

Cool Chamber Die Casting is the Best Choice for Aluminum Casting Products

When it comes to selecting the right pressure die casting process, manufacturers often compare hot chamber and cold (cool) chamber die casting. Although both use high pressure to inject molten metal into a mold, they are designed for very different materials. For aluminum alloys, cool chamber die casting is unquestionably the best choice. Let’s explore why this process stands out and how it ensures top-quality aluminum casting products.

Understanding Cool Chamber Die Casting

In the cool chamber process, molten aluminum is melted in a separate furnace. Then, it is ladled into an unheated injection chamber and forced into a steel mold under high pressure. Since the molten metal doesn’t sit inside the injection system, the equipment stays cooler—hence the name cool chamber die casting. This design protects machine components from extreme temperatures and prevents unwanted chemical reactions between molten aluminum and steel parts, resulting in consistent, high-quality castings.

Why Hot Chamber Die Casting Isn’t Suitable for Aluminum

Hot chamber die casting uses an integrated melting pot, where the injection mechanism (gooseneck and plunger) remains submerged in molten metal. This setup is efficient for low-melting-point materials such as zinc and magnesium. However, aluminum melts at around660°C (1220°F), a temperature too high for hot chamber systems. If aluminum were used, it would rapidly corrode the submerged steel components, contaminate the alloy, and shorten equipment life. Therefore, hot chamber die casting is not used for aluminum production.

Benefits of Cold Chamber Die Casting for Aluminum

- High strength and durability:Ideal for complex aluminum components that require mechanical performance.

- Better alloy purity:Prevents iron contamination and maintains consistent metal composition.

- Improved machine life:Reduces thermal damage and corrosion on injection components.

- Larger casting capability:Supports bigger and thicker aluminum parts with consistent quality.

- Excellent precision:Achieves tight tolerances and smooth surface finishes suitable for post-processing.

Why TEAM RAPID Chooses Cool Chamber for Aluminum

At TEAM RAPID, we use advanced cool chamber die casting machines to produce high-quality aluminum parts for global customers. Our team understands the unique challenges of aluminum casting — from managing high temperatures to ensuring tight dimensional tolerances. By combining precision tooling, strict quality control, and expert craftsmanship, we deliver aluminum die castings that meet the highest industry standards for strength, accuracy, and appearance.

Discover Our Aluminum Die Casting Process

At TEAM RAPID, we specialize in precision aluminum die casting to create high-quality, durable parts for a wide range of industries. Our advanced rapid manufacturing technology allows molten aluminum alloys to be injected under high pressure into steel molds, forming complex shapes with excellent strength, accuracy, and surface finish. This process ensures consistent quality and performance in every product we deliver.

Watch the video below to see how our aluminum die casting process works — from molten metal to finished parts:

Aluminum Die Cast Alloys at TEAM RAPID

TEAM RAPID is a professional aluminum die casting manufacturer in China. Our aluminum pressure die casting serves a wide range of industries. In the past ten years, we made a series of motor housing, die-throwing heat sink, exhaust fan, aluminum enclosure, die cast aluminum cookware, washing machine handle, camera housing, led housing, etc. ADC12 and A380 aluminum die cast are the most popular aluminum die casting alloys at TEAM RAPID.

Aluminum Casting Alloys - Die cast Aluminum ADC12

ADC12 (Al-Si-Cu-based cast aluminum alloys) have good castability and high mechanical properties. These alloys are commonly used for complicated automotive parts such as transmission cases, cylinder blocks, converter housings, etc. It is also one of the most widely used metal choices for many die-casings produced internationally.

Die Cast Aluminum Alloy - Die cast Aluminum A380

A380 aluminum die cast is one of the most commonly used die casting aluminum alloys. Benefits from its’ good performance, A380 is widely used in many applications.

It has the best combination of mechanical, casting, and thermal properties.

It has pressure tightness, excellent fluidity, and resistance to hot cracking.

It is widely used in various products, including die cast aluminum heat sinks, engine brackets, chassis for electronic equipment, household furniture, die cast aluminum cookware, gearbox cases, hand tools, etc.

Other Aluminum Alloy for Pressure Die Casting

While ADC12 and A380 are the most widely used alloys in high-pressure die casting, manufacturers often choose from several other aluminum grades to achieve specific mechanical, thermal, or corrosion-resistant requirements. Below are the most common alternatives and what makes them valuable for modern die-cast components.

| Alloy | Key Features | Advantages | Typical Applications |

|---|---|---|---|

| A360 | High corrosion resistance, good ductility, stable at high temperature | Better strength than A380, good dimensional stability | Outdoor housings, automotive parts, enclosures |

| A383 | High silicon content, excellent castability | Ideal for thin-walled and complex geometry parts | Electronics housings, connectors, intricate components |

| A413 | Excellent fluidity, low porosity, high pressure tightness | Best choice for leak-proof and pressure-containing parts | Pump bodies, valve housings, hydraulic components |

| B390 | Very high hardness and wear resistance | Extremely durable under friction and abrasion | Engine parts, pistons, cylinder blocks |

| A514 (ADC6) | Balanced strength and corrosion resistance | Good structural stability and mechanical performance | General engineering parts, structural components |

| AlSi10Mg | High strength-to-weight ratio, heat-resistant, heat-treatable | Can be age-hardened for higher performance | Automotive structural parts, aerospace brackets, precision parts |

Post-Manufacturing Options for Aluminum Die Casting Parts

After aluminum parts are produced by high-pressure die casting, various post-manufacturing processes can be applied to improve their appearance, corrosion resistance, dimensional accuracy, and overall performance. Choosing the right finish depends on your application, functional requirements, environment, and cost targets. Below are the most common finishing processes for aluminum die castings:

Post-Machining

Post-Machining

Post-machining is essential for aluminum die castings when your parts require tighter tolerances, cleaner surfaces, or features that cannot be produced by casting alone. Common machining operations include CNC milling for accurate flat surfaces and pockets,CNC turning for round or cylindrical features, and drilling, tapping, and reaming for precise holes and threaded connections. Additional processes such as surface grinding, broaching, honing, andCNC trimming help refine critical surfaces, create internal shapes, and remove excess material left from casting. Together, these machining methods deliver the final precision, function, and assembly readiness needed for high-quality aluminum die-cast components.

Post-Finish Options

Aluminum pressure die casting parts can be enhanced through various post-finishing processes that improve appearance, durability, and performance. Common surface finishing options include deburring and blasting to smooth the surface, polishing for a premium aesthetic, and anodizing or powder coating for corrosion protection and color. Painting, electroplating, and chromate conversion (Alodine)offer additional cosmetic and protective solutions.

Functional finishes such as porosity sealing (impregnation)ensure leak resistance in pressure-tight components, while laser marking provides permanent identification without damaging the part. Together, these finishing treatments help manufacturers meet specific cosmetic, environmental, and performance requirements for high-quality aluminum die cast products.

TEAM RAPID: One-Stop Services from Die Making to Casting and Surface Finish

TEAM RAPID provides a full one-stop solution for aluminum die casting—from tooling design and die making to precision casting, CNC machining, and final surface finishing. Our integrated process ensures consistent quality, faster lead times, and cost-effective production.

TEAM RAPID provides a full one-stop solution for aluminum die casting—from tooling design and die making to precision casting, CNC machining, and final surface finishing. Our integrated process ensures consistent quality, faster lead times, and cost-effective production.

With complete in-house capabilities, we deliver cast parts that meet tight tolerances, achieve the required appearance or protection, and are fully ready for assembly. TEAM RAPID streamlines your entire manufacturing process, saving time and ensuring reliable results from start to finish.

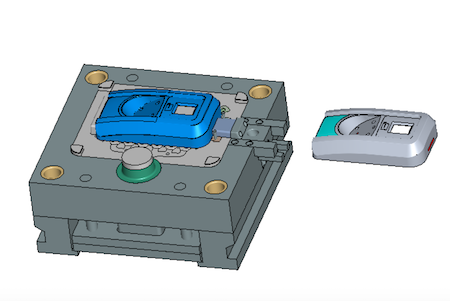

Die Casting Mold Making

Die casting mold making is the foundation of producing accurate and high-quality aluminum cast parts. At TEAM RAPID, every mold begins with detailed engineering, proper material selection, and optimized flow and cooling design to ensure long tool life and stable production. Our mold-making process includes CNC machining, EDM, heat treatment, and precision fitting to achieve tight tolerances and consistent performance. With well-built molds, customers benefit from faster cycle times, improved part quality, and reduced manufacturing costs.

Aluminum Casting Process

The dies are mounted into a die casting machine. Then the molten aluminum is injected into the dies under high pressure. Once the molten die cast aluminum has solidified, the mold is opened, and the casting is removed from the die. The mold is then closed, and the process starts over. The cycle time for the aluminum die casting process depends on the part weight and size. Typically, the bigger part, the longer the cycle time. Contact us for aluminum die casting now!

Low Volume Aluminum Die Casting

Low Volume Aluminum Die Casting is an ideal manufacturing solution for customers who need high-quality aluminum parts in small to medium quantities without investing in expensive mass-production tooling. At TEAM RAPID, we provide flexible, fast and cost-effective low-volume die casting services to support prototype validation, market testing, pilot runs and bridge production before full-scale manufacturing.

Typical Production Volumes

| Stage | Estimated Quantity | Purpose |

|---|---|---|

| Prototyping | 1 – 50 pcs | Function & performance testing |

| Pilot Run | 50 – 2,000 pcs | Market validation & certification |

| Bridge Production | 2,000 – 10,000 pcs | Transition before mass production |

Why TEAM RAPID

-

In-house tooling, casting, machining & finishing

-

Rapid prototypes to production using A380, ADC12, AlSi10Mg, etc.

-

Experienced engineering for DFM & cost optimization

-

Strict quality control: CMM, X-ray, leak testing & material reports

-

Fast quotation, global delivery, no MOQ

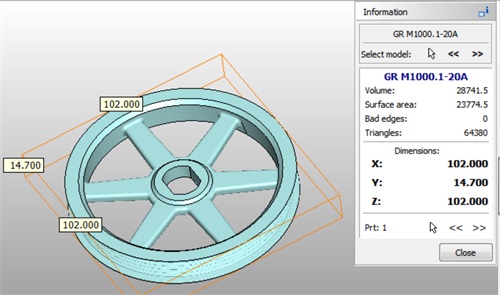

Aluminum Pulley Wheel Casting - Case Study

Inquiry from Customer

Hi, I attached a STEP file and a drawing (with notes, part to be as cast, no machining).Please quote as follows:

1) Material: Aluminum (Standard Cast Grade) and/or Steel (Standard)2) Quote per your MIN Qty order...or... as 500 parts yearly.

3) What's the time frame for Prototype & Aluminum Die Casting Production?

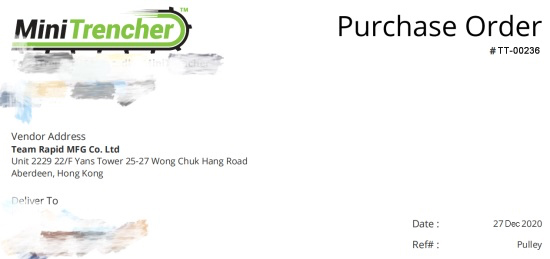

Placed Order

Dear TEAM Rapid MFG Co. Ltd,

The purchase order (TT-00236) is attached with this email.

An overview of the purchase order is available below

----------------------------------------------------------------------------------------

Purchase Order #: TT-00236

----------------------------------------------------------------------------------------

Order Date 27 Dec 2020

----------------------------------------------------------------------------------------

Please go through it and confirm the order. We look forward to working with you

Customer Feedback

Thank you Jason, we received these parts successfully this morning.

It's amazing to look at the molds taking shape through your updates -- some of these parts are complex, but I like that way you guys make them look easy! Thanks again for helping us meet our aggressive schedule! The part works excellent! Do you work at zinc die casting? What is the different between zinc die casting vs aluminum die casting? Our new project is coming.

-Sergio

Aluminum Die Casting vs. CNC Machining: How to Choose

When producing aluminum parts, Aluminum Die Casting and CNC Machining are two of the most popular manufacturing methods. Both offer excellent precision and performance, but each is better suited for specific project needs. Understanding the differences allows you to select the most cost-effective and efficient method for your product.

1. What is Aluminum Die Casting

Aluminum die casting is a process where molten aluminum is injected into a steel mold under high pressure. It is ideal for medium-to-high volume production and for parts with complex shapes, thin walls and detailed features.

2. What is CNC Machining

CNC machining is a computer-controlled subtractive manufacturing method where material is precisely cut from a solid aluminum block. It is perfect for low-volume production, prototypes and parts requiring very tight tolerances.

Comparison Table

| Criteria | Aluminum Die Casting | CNC Machining |

|---|---|---|

| Production Volume | Medium to High | Low to Medium |

| Initial Tooling Cost | Higher | No tooling cost |

| Unit Cost (Large Qty) | Very Low | Higher |

| Accuracy / Tolerance | Good | Excellent |

| Part Complexity | Very High | Medium to Very High |

| Surface Finish | Very Good (Post-Finishing Available) | Excellent |

| Lead Time | Moderate (Tooling Required) | Short |

| Material Usage | Highly Efficient | Higher Material Waste |

| Best For | Mass production & complex shapes | Prototypes & precision parts |

How to Choose the Right Process

Choose Aluminum Die Casting if:

-

You require100+ pcs to thousands of parts

-

Reducing unit price is a priority

-

Your part has complex geometry, thin walls, or multiple features

-

You want near-net-shape production with optional post-processing

Choose CNC Machining if:

-

You need1–100 pcs or prototype samples

-

Extremely tight tolerance or premium finish is required

-

The design may change frequently

-

You prefer no upfront tooling investment

Expert Recommendation from TEAM RAPID

For product development, many customers choose CNC prototyping, then switch to aluminum die casting for pilot runs and mass production. TEAM RAPID provides both services, allowing you to scale smoothly from prototype to volume manufacturing while maintaining design consistency and quality standards.

Need Help Deciding?

Send your 2D/3D files and project requirement, and our engineering team will evaluate:

- Cost per unit

- Tolerance needs

- Material and surface options

- Lead time & volume planning

TEAM RAPID is one of the best aluminum die casting companies. We are pretty sure we can help you. Contact Us at [email protected] today. Here, we offer one-stop manufacturing services to meet your aluminum die casting needs!

Frequently Asked Questions

What is Die Cast Aluminum(What is High Pressure Aluminum Die Casting)?

The aluminum used in die casting process. Aluminum variants are not the same. They can have significant variations in certain characteristics, such as their weight, fatigue strength, electrical conductivity, and melting point.

Here are some of the popular die casting aluminum and their advantages:

ADC12: Aluminum A380 is a cost-effective and highly mechanical material. It features excellent pressure tightness, fluidity, and thermal properties

A380 and A383: Due to its various advantages, some companies choose to use A383 as an alternative to A380. This type of aluminum has better dimensional stability and corrosion resistance.

A413: For applications that require high pressure tightness, such as hydraulic cylinders, A413 is a good choice.

How to Die Cast Aluminum(How Aluminum Die Casting Works)?

Casting aluminum products using a steel die involves injecting liquid aluminum into the mold. This process produces a product that's exact in its shape. The process generally follows these steps:

1. Creating the Die.

2. Choose the right size machine and set up the die.

3. Injecting the aluminum.

4. Cooling the aluminum.

5. Remove the gate and overflows.

Can You Anodize Die Cast Aluminum(Can Aluminum Die Casting be Anodized)?

Although anodizing die-cast aluminum can be done, it is not always feasible. This process involves various obstacles and challenges. Aluminum die-casting parts can be anodized, but achieving the desired surface properties can be challenging. In our opinion, aluminum die-casting parts are not suitable for anodizing.

Although sulfuric acid anodizing can be used for common die-cast aluminum alloy types, such as Al Si, Al Cu, and Al Mg, it is not suitable for most of them. On the other hand, some die-casting aluminum products, such as aluminum manganese alloy DM32, can be colored and anodized with good anodization and die casting performance.

The main reasons why aluminum die-casting components are unsuitable for anodizing are the cost factors and the composition of the aluminum alloys. The anodizing process involves using various alloy parts as anodes and cathodes. These components are then subjected to a proper electrolyte. Anodized film produced on pure aluminum exhibits the best properties, such as its hardness and resistance to corrosion. The anodized film is then produced on the component's surface by oxidation under certain current and voltage conditions. In the anodizing process, sulfuric acid is used to color the aluminum components. This process can decrease the quality of the film. The required aluminium content to get the best possible oxidation effect is usually around 95%. When copper, silicon, and iron are used in the anodizing process, the resulting film will be red, and it will damage the electrolyte and cause oxidation defects. High silicon content in die-casting aluminum components makes it impossible to produce transparent and colorless oxide film. As a result, cast aluminum alloy is not ideal for anodizing. The resulting film will also change its color from light grey to black-grey due to the increase in silicon content. The increased silicon content will also change the film's color from light grey to black-grey. This makes cast aluminum alloy unsuitable for anodizing.

Cast Al alloys are commonly used for various applications, such as aerospace and automotive, due to their fluidity and ease of production. However, if you want a perfect surface finish, then secondary processing is required. The addition of silicon, which is not anodizing upon solidification, to the melt allows for the fluidity of melt aluminum. Unfortunately, the topography and chemistry of the cast surface are not uniform and complex, which can prevent anodizing die-casting aluminum. In addition, a non-standard bath can lead to multiple trials and errors, increasing costs. The cast surface's topography and chemistry aren't uniform, and anodizing aluminum alloys won't perform well. Also, a non-compliant bath can lead to errors and multiple trials, resulting in additional costs.

Is Die Cast Aluminum Cookware Safe(Is Die Cast Aluminum Safe for Cooking)?

Various types of utensils, such as pots and pans, are made from aluminum, which is a sustainable material. Die-casting is a process that makes it easier to use. The aluminum is melted after high heat, and a mold is created. Once the mold is filled with the melted aluminum, it will get shaped. This process then produces beautiful and functional forms.

Since aluminum is a non-toxic metal, it shouldn't be considered a concern when it comes to using aluminum-based products. These types of pots and pans are made from die casting alloys aluminum, which is harmless to our health.

Does Die Cast Aluminum Rust?

Unlike other types of metal, die cast aluminum won't rust. This material is great for outdoor products as it won't break down if exposed to humid weather, snow, or rain. It will also keep its appearance beautiful for many years. Not only will your products look great for many years, but you won't have to worry about any rust stains on aluminum die casting alloys.