High-quality Clear Plastic Injection Molding Parts

At TEAM RAPID, we specialize in premium clear plastic injection molding services built for precision, transparency, and durability. Over the past decade, hundreds of clients—from consumer goods to industrial applications—have trusted us to produce crystal-clear parts like lamp covers, light pipes, lens shields, clear cups, panels, and more. Our reputation is built on exceptional quality, strict tolerances, and fast, reliable delivery.

Light Guide

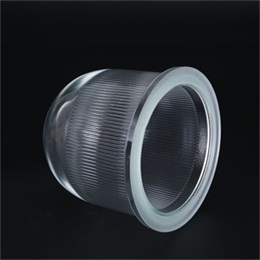

Lamp Cover

Lens Cover

Clear Plastic Cup

What Is Clear Plastic Molding

Clear plastic molding is a specialized injection molding process used to produce transparent parts with excellent optical clarity and surface quality. It allows manufacturers to create components like light covers, lenses, display panels, and transparent housings from materials such aspolycarbonate (PC), acrylic (PMMA), and clear ABS.

Clear Plastic Molding vs. Standard Injection Molding — Key Differences

When choosing the right injection molding process, understanding the difference between clear plastic molding and standard injection molding is essential. Clear plastic molding is designed to produce transparent or optical-grade parts that demand perfect clarity, such as lenses, light pipes, and see-through covers. In contrast, standard injection molding focuses on opaque or colored plastic parts where appearance, texture, or paint finish can hide minor surface flaws.

At TEAM RAPID, we specialize in both clear and standard injection molding solutions. Whether your project requires high-clarity transparent components or cost-effective opaque housings, our experienced engineers ensure top-quality results through precise tooling, optimized mold design, and strict process control.

Commonly Used Materials for Clear Plastic Molding

| Material | Transparency | Impact Resistance | Heat Resistance | Scratch Resistance | Typical Applications | Key Advantages |

|---|---|---|---|---|---|---|

| Polycarbonate (PC) | Excellent (88–90%) | ★★★★★ Very High | ★★★★☆ | ★★★☆☆ | Light covers, lenses, protective housings | High impact strength, optical clarity, good dimensional stability |

| Acrylic (PMMA) | ★★★★★ Excellent (up to 92%) | ★★☆☆☆ Moderate | ★★★☆☆ | ★★★★★ Excellent | Display panels, lighting components, consumer product covers | Highest transparency, great surface polish, UV stability |

| Transparent ABS | ★★★☆☆ Good | ★★★★☆ High | ★★★☆☆ | ★★☆☆☆ | Electronic housings, automotive interiors | Toughness, machinability, moderate clarity |

| Polypropylene (PP) | ★★★☆☆ Moderate | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ | Food containers, lab ware, household products | Lightweight, chemical resistant, food-grade safe |

| PETG | ★★★★☆ Very Good | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | Packaging, displays, protective covers | Easy processing, impact resistance, clear appearance |

Materials Selection Matters

Each clear plastic material has unique molding behavior and performance characteristics. At TEAM RAPID, our engineers analyze your product’s design, thickness, and functional requirements to recommend the most suitable transparent resin. With our precision tooling and expert polishing, your clear plastic parts achieve superior clarity, strength, and long-term stability.

Clear Plastic Molding Finishes – TEAM RAPID

Selecting the right molding finish for clear plastic is essential for achieving high-quality, transparent plastic parts with superior clarity and appearance. At TEAM RAPID, we specialize in custom injection molding with finishes tailored to your application, from optical components to decorative housings.

Why Molding Finish Matters for Transparent Plastic Parts

The surface finish impacts:

- - Clarity and transparency for lenses, covers, and display panels.

- - Aesthetic appeal with high-gloss, satin, or textured options.

- - Functionality including grip, friction, and post-processing ease.

Popular Clear Plastic Injection Molding Options

Finish

Description

Best For

Mirror Polish (SPI A/B/C)

Ultra-smooth, glossy surfaces with minimal defects.

Lenses, medical devices, optical parts.

Textured / Matte (SPI H/V, VDI)

Fine texture reduces glare and hides minor imperfections.

Packaging, housings, consumer electronics.

Satin / Semi-Gloss

Balanced surface between gloss and matte.

Decorative parts, prototypes, functional components.

How to Choose the Right Finish

-

1.Determine the part’s purpose– Optical parts need mirror polish; housings may benefit from textures.

-

2.Consider post-processing– Some finishes polish or coat more easily.

-

3.Balance quality and cost– Mirror finishes require precise mold polishing, affecting tooling cost.

Benefits of Clear Plastic Injection Molding

Clear plastic injection molding offers exceptional functional and visual advantages that make it ideal for both industrial and consumer applications. From optical clarity to durability, this process ensures every product looks sleek, performs reliably, and lasts long.

Benefit

Description

Transparent Design

Elegant, modern appearance with glass-like clarity

Non-Toxic

Safe for food, beverage, and medical use

UV Resistance

Withstands sunlight without yellowing or cracking

Scratch Resistance

Protects surfaces from wear and damage

Lightweight Strength

Stronger and safer alternative to glass

Design Flexibility

Supports complex, precise, and aesthetic designs

Chemical & Weather Resistance

Durable under various environments

Catalog of Clear Plastic Injection Molded Products

Below is a curated showcase of product categories made by clear plastic molding, with explanations of their functions, materials, and value proposition.

1.Light Guides & LED Covers / Diffusers

Description & Use Cases

- Transparent components that channel or diffuse light for LED arrays, signage, backlit displays, architectural lighting, and automotive lighting.- These parts require uniform light transmission, minimal haze, and consistent thickness.

Materials Often Used

- Optical-grade PMMA (acrylic)

- Polycarbonate (PC)

- Specialty grades with light diffusion additives

Key Advantages

- Smooth surfaces and precise geometry minimize optical distortion

- Allows compact and efficient lighting modules without bulky optics

2.Lenses & Optical Components

Description & Use Cases

Description & Use Cases

- Precision lenses, prisms, waveguides, camera covers, sensor windows for medical, automotive, or machine vision systems.

Materials & Requirements

- Highly transparent grades of PC, PMMA, or cyclic olefin copolymer (COC)

- Tight tolerances (e.g. surface flatness, curvature)

- Control over birefringence, internal stress, and surface quality

Value

- Allows integration of optics directly into assembly

- Reduces need for secondary machining or glass optics

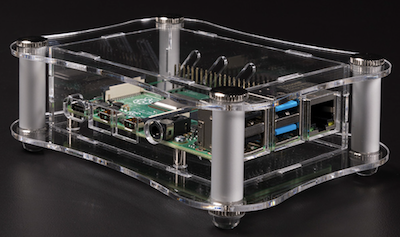

3.Transparent Enclosures, Display Windows & Covers

Description & Use Cases

Description & Use Cases

- Housings for consumer electronics, control panels, instrument displays, machine sight windows, protective covers.

Material & Design Considerations

- Clear grades with scratch resistance (e.g. coated PC)

- Possibility of integrating gasket seals, snap-fits, hinges

- Molded flush surfaces with polished finish

Benefits

- Seamless “see-through” aesthetics with functional protection

- One-piece design reduces assembly and subsequent sealing

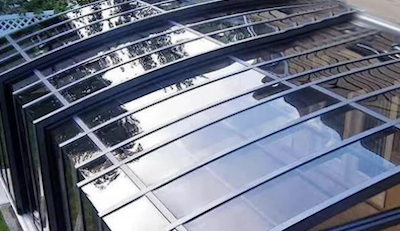

4.Outdoor Panels, Roofing & Architectural Components

Description & Use Cases

Description & Use Cases

- Transparent or translucent roof panels, skylights, awnings, light-transmitting fades, guard rails.

Material Strategies

- UV-stabilized PC or acrylic, or co-extruded / co-molded variants

- Reinforced or thick sections to maintain structural integrity

Why Clear Molding Matters Here

- Long-term clarity under sun exposure

- Weather resistance, scratch resistance, minimal yellowing

- Lighter and safer than glass alternatives

5.Food & Beverage Containers with Transparent Elements

Description & Use Cases

Description & Use Cases

- Portions of bottles, jars, lids, spouts, food bins, beverage components where transparency shows content.

Important Material Qualities

- Food-grade, BPA-free, non-toxic clear plastics

- Resistance to cleaning, washing, and repeated use

Advantages

- Consumers can see contents — good for marketing & inspection

- Transparency combined with durable molding gives safer, more attractive packaging

6.Medical & Laboratory Components

Description & Use Cases

Description & Use Cases

- Transparent chambers, fluidic devices, catheter housings, microscope covers, sample vials, sight windows.

Critical Requirements

- High optical clarity, chemical resistance, sterilizability

- Low water absorption, biocompatibility

Why Clear Molding Helps

- Enables visual monitoring of fluids or reactions

- Can integrate precise ports, snap features, and optical windows

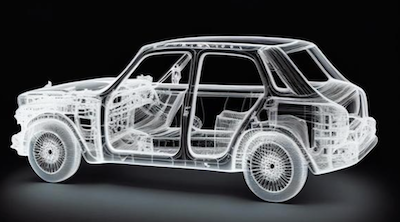

7.Automotive Transparent Components

Description & Use Cases

Description & Use Cases

- Headlamp lenses, tail lamp covers, turn signal housings, interior display shields, dashboard windows.

Material & Performance

- UV- and weather-resistant PC or PMMA blends

- High impact resistance, clarity, and durability

Benefits

- Lightweight alternative to glass

- Complex shapes and integration directly via injection molded process

8.Safety Shields, Guards & Transparent Barriers

Description & Use Cases

Description & Use Cases

- Machine guards, face shields, protective windows, sneeze guards, control room view panels.

Material Attributes

- Tough clear polycarbonate (PC) preferred for impact resistance

- Anti-scratch coatings, glare-reducing surface treatments

Value Provided

- Transparent barrier protection without sacrificing visibility

- Sturdy and safe replacement for glass in industrial settings

Why TEAM RAPID for Your Clear Injection Molding Parts

At TEAM RAPID, we specialize in high-quality, cost-effective clear plastic injection molding solutions. As one of the leading plastic molding manufacturers in China, we understand that both mold making and plastic part molding are equally important for achieving outstanding results. A well-designed and precisely built mold is the foundation for producing high-quality clear plastic components with perfect transparency, strength, and surface finish. Our expert team ensures every detail meets your requirements for optical clarity and durability.

1. Choosing the Right Steel for Clear Plastic Mold Making

Selecting the proper tool steel is crucial for the mold’s longevity and the surface finish of transparent parts.

At TEAM RAPID, we commonly use:

- NAK80

- S136

- S136H

For low-volume production, such as clear plastic covers or transparent prototypes, we recommendNAK80 or S136H. These steels deliver excellent results for up to 50,000+ molding cycles without heat treatment. For mass production, heat-treated S136 is ideal due to its superior hardness, corrosion resistance, and ability to produce crystal-clear molded surfaces that maintain quality over thousands of cycles.

High-grade mold steel = consistent optical clarity + long mold life.

2. Selecting the Right Material for Clear Plastic Molding

Material selection determines clarity, durability, and performance of your final molded product. TEAM Rapid offers a wide range of transparent injection molding materials, including:

| Material | Key Features | Common Applications |

|---|---|---|

| PMMA (Acrylic) | Excellent transparency, high gloss | Light covers, lenses, displays |

| PC (Polycarbonate) | Impact resistant, UV stable | Safety shields, light pipes |

| PS (Polystyrene) | High clarity, affordable | Packaging, lab ware |

| Clear ABS | Toughness with semi-transparency | Functional housings |

| PP (Polypropylene) | Chemical resistant, flexible | Containers, medical parts |

For optical parts like lenses or light guides,PMMA or PC are the best options due to their high light transmittance and surface finish. However, changing to clear PP will affect optical performance and gloss. Our engineers can help you select the ideal material based on your application’s mechanical and optical requirements.

Contact us at [email protected] for free material consultation.

3. Surface Finishes for Clear Plastic Molded Parts

As a professional injection mold maker, TEAM Rapid follows SPI (Society of the Plastics Industry) standards for all finishing processes.

We commonly provide:

- SPI-A2 and SPI-A3 Mirror Finishes

- Texture and Sandblasting Finishes

- Custom Optical Finishes (for light pipes or lenses)

For optical applications, we can adjust the light diffusing agent ratio in the molding material to achieve the ideal light transmission and diffusion.

A precision-polished mold surface ensures maximum transparency and minimal flow marks.

4. Using the Correct Injection Molding Machine Size

Matching the right injection molding machine to your part size is critical for quality.

Using a machine that’s too large can lead to:

- Silver streaks

- Air bubbles

- Gloss or flow defects

At TEAM RAPID, we operate injection molding machines from 50 to 500 tons, allowing us to handle a wide variety of clear plastic parts efficiently — from small transparent components to large covers and enclosures.

We focus on every detail:

- Optimized part design

- Smart mold flow analysis

- Precise mold fabrication

- Accurate injection parameters

Our end-to-end process ensures your clear plastic parts are free of bubbles, warping, or optical distortion.

What Our Customers Are Saying

“We needed high-optical clarity lens covers for our LED fixtures—TEAM RAPID delivered parts with perfect transparency and no visible defects. The finish is mirror-like and the injection molding quality exceeded our expectations!”

—Amanda Lee, Product Engineer

“From prototype to production, the clear plastic cups TEAM RAPID made for us came out crisp, clean and consistent. Their team’s guidance on material selection (we used PMMA) and mold finish was spot on. Excellent service!”

—Carlos Mendes, Packaging & Design Manager

“The clear plastic roof panels for our architectural project required UV resistance, low haze, and excellent scratch resistance. TEAM RAPID’s craftsmanship kept everything within tight tolerances and optical performance specs. We’re extremely happy with the results.”

—Lisa Chang, Project Architect

Frequently Asked Questions

How to Make Plastic Molds?(How to Make a Plastic Mold?), (How to Make Plastic Mold?)

The workflow of making plastic molds is as followings: survey and map the product, make a 3D drawing of this product, mold design, then buy some accessories such as mold steel according to the mold drawing, then process machining according to the drawing, and finally assemble a mold, after successful mold testing, put into production.

The plastic molds making process involves wired cutting, spark machine, CNC machining, milling machine, grinding machine, lathe, rotten flower, etc. the structure of the product/mold determines all these.

How to Mold Plastic?

The molded plastic methods are roughly divided into four methods: compression molding, extrusion, injection molding, and blow molding.

Compression Molding

The process of compression molding involves first putting fibrous or granular materials into a mold cavity at a set temperature. After closing the mold, it presses it to form and solidify. This process can be used for various materials such as rubber, thermoset, and thermoplastics.

Extrusion

Extruded materials are used in this process to make various semi-products or cross-sectional products. The products are pushed forward through the action between an extrusion barrel and a plasticized and heated nut.

Injection Molding

Injection molding is a process utilized to create parts for various products. Usually, these are molded using plastic and rubber. There are two main methods of injection molding: compression molding and die casting. The former is used to make plastic products, while the latter is used for thermoset materials. The main equipment used for this process is an injection machine. These machines mold various plastic products, such as those used for thermoset materials.

Blow Molding

The rapid emergence and evolution of blow molding have made it a widely used plastic processing technique. In this process, a tubular plastic blank is placed inside a split mold and heated to a soft state. Compressed air is then introduced into the blank after the mold has closed, which allows it to remain in its original state and form a resilient and inflated product. To make the most of this process, you need to create a window that contains at least five paragraphs and more than one hundred words. For optimal predictions, go for five or more paragraphs.

Do It Soft Plastic Molds?

Soft plastic molds are usually made in silicone, and we also name soft plastic molds silicone molds. As the mold is soft, it is easy to wear and damage, so it is applied in low-volume manufacturing with resin materials.

what is Plastic Injection Molding?

Injection molding is a process utilized to produce components that are made of thermoset or thermoplastic materials. It involves heating and melting the plastic in the injection machine's barrel. The molten plastic is moved forward and compressed under the pressure of a plunger or a screw. It is then injected into a closed mold, cooled, and shaped after a certain time. The injection process is performed in a batch manner. It involves an injection device, a clamping device, and a mold. The mold can be fixed in either a vertical or horizontal position.

How to Make a Mold for Plastic?

Several types of molds can be used to mold plastics. There are mainly steel molds, aluminum molds, silicone molds, 3d print molds. Depending on the plastic part's structure, size, and accuracy, the choice of mold material is different. The steel mold can have good quality plastic parts at tight tolerance and excellent finish while the long mold building lead-time. 3d print molds and silicone molds have short mold lead-time, but the molded parts are not as good as the ones made by steel molds. How to make a mold for plastic? If you want to DIY, we suggest silicone molds. The whole process can be made by hand without lots of investments in the tools.

1. You need to have a master.

2. Make a box and hang the master into the box.

3. pour the silicone into the box.

4. Take out the master when the silicone is dry.

5. Pour the resin into the silicone mold, then copy the parts.

What is The Most Durable Injection Molding Plastics for Clear Parts?

PC and ABS should be the most 2 durable injection molding plastics for clear parts.

PC is hard and strong molded plastic that can withstand high impact. The material can be used as a lens cover.

ABS displays the synthesis working ability, it is flexible and not so easy to crack, but it is not very clear molding plastic.

Clear mold plastics such as PC, ABS, HDPE, PP, etc., are commonly used at TEAM Rapid. Contact us for more details about clear plastic molding resins.

How to Make Cheap Clear Plastic or Resin for Molding?

The clear injection molded plastics or resins take a small amount of the moldings; the main costs for your clear injection molded parts are the tooling and molding process! It would be best if you got a low-cost, one-stop tooling and molding manufacturer to help you. Research on Google, and you can have a list of tooling and molding manufacturers in China. They are happy to quote for you! Then you can pick up the one at a reasonable price for your parts, or you can send us an email directly requesting a plastics injection molding quote.