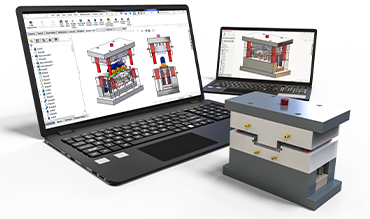

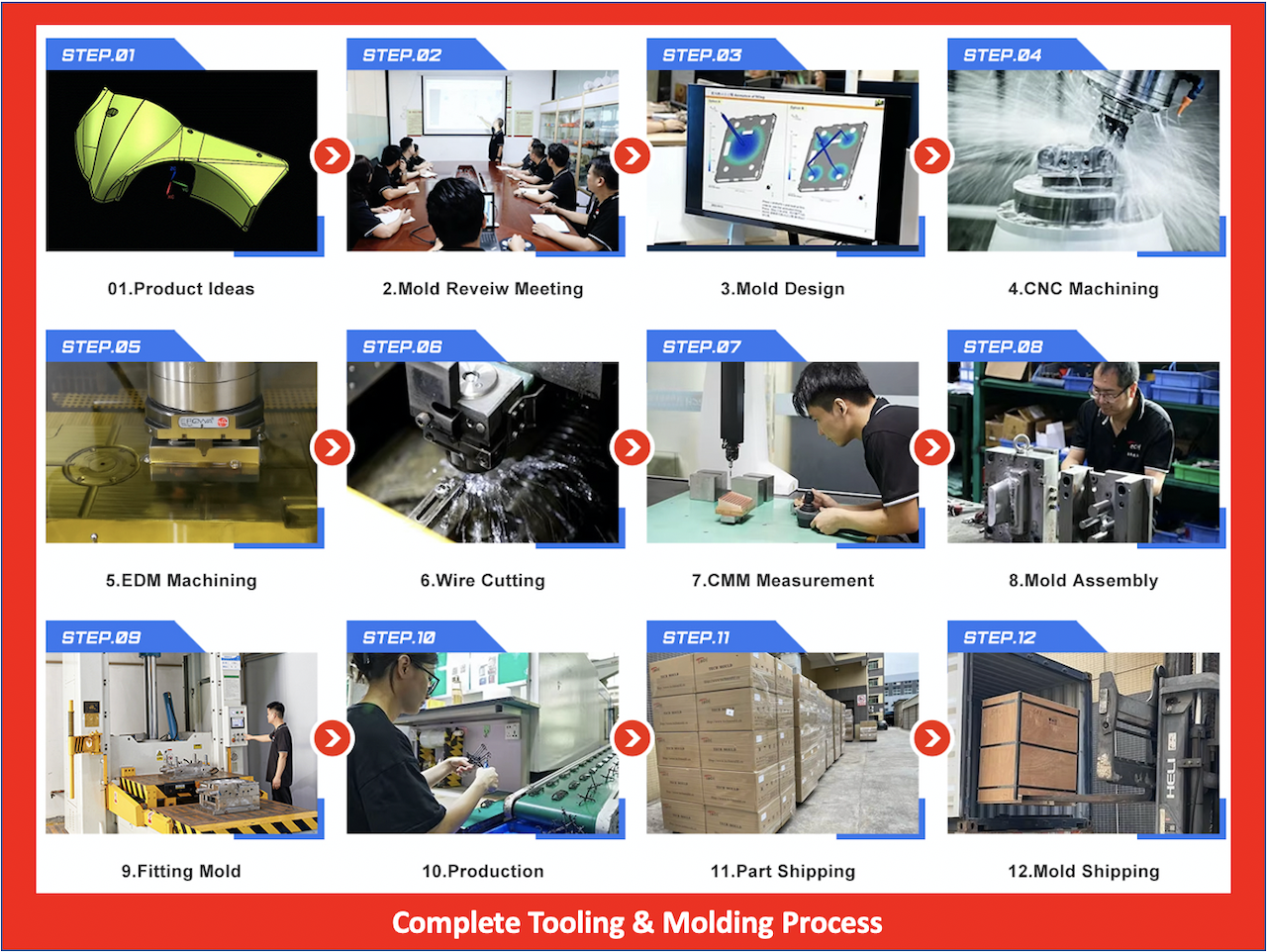

Prototype Tooling & Production Molds - Strong Manufacturing Supports

Combining the traditional tooling methods, TEAM RAPID uses advanced rapid tooling approaches to support projects ranging from small-batch orders to full-scale production.We offer 3 core tooling options depends on the product requirements, complexity, and timeline.Each method is selected to give our customers the best balance of speed, quality, and cost-efficiency.

- Prototype Tooling: prototyping tool lifetime ups to 5,000 shots for prototyping and low-volume production.

- Bridge tooling: tool lifetime ups to 100,000 shots for medium volume production.

- Production tooling: tool lifetime ups to 1,000,000 + shots for mass production.

Tooling Methods Comparing Table

| Tooling Type | Best For | Typical Lead Time | Tool Life (Shots) | Material / Structure | Key Benefits |

|---|---|---|---|---|---|

| Prototype Tooling | Early design validation, functional testing, low-volume parts | 1–2 weeks | 500–5,000 | Modular structure, shared mold base | Fastest delivery, cost-effective, easy to modify, supports design iterations |

| Bridge Tooling | Pilot runs, medium-volume production, transition to mass production | 1.5–4 weeks | Up to 100,000 | Steel tooling for improved durability | Ideal middle solution, better surface finish, supports simple & complex designs |

| Production Tooling | High-volume manufacturing, long-term product lines | 4+ weeks | 1,000,000+ | Robust steel construction, multi-cavity options | Highest precision, long tool lifespan, lowest cost per part |

Have questions about tooling method selection? Our experienced sales engineers will provide professional suggestions, we will base on your parts’ structure and on-demanded quantities to suggest the best solution for you! We aim to offer high-quality parts at minimum cost. Request a quote now.

Prototype Tooling

Prototype Tooling is a useful method to verify and test the product designs before committing to full-scale production. It allows you to evaluate the products’ functionality, fit, and manufacturability while keeping low costs and short turnaround time.

-

Key Features

1. Shared mold base(MUD) and changeable tooling components to shorten prototype tooling time.

1. Shared mold base(MUD) and changeable tooling components to shorten prototype tooling time.

2. Tooling time ranges from 1-2 weeks. Small tool with simple cavity geometry can be built up as little as 7 days.

3. Tooling life time ranges from 500 - 5,000+ shots depends on the mold material.

4. Family mold & Multi-Cavity Mold Available.

5. Design flexibility and quick tooling modifications available.

6. Wide range of real materials can be used, not only the common thermoplastics but also engineering plastics.

7. Traditional molding finish available.

8. Low tooling investment, good for small batch production.

9. 2 years’ free store time and tool maintenance.

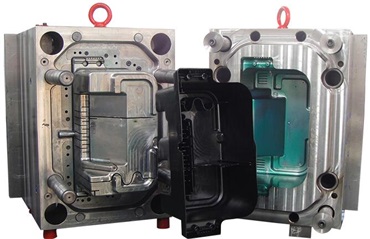

Bridge Tooling

Bridge Tooling is the bridge between prototype tooling and full-scale production tooling, it is a solution for the customers to make products to test the market, and do the promotion. Also,It allows manufacturers to produce parts in medium volumes while validating design, production processes, and material selection before investing in permanent production molds.

-

Key Features

1. Perfect for low to medium-volume production.

1. Perfect for low to medium-volume production.

2. Steel mold to guarantee the tool's lifetime & excellent surface finish.

3. Bridge Tooling lead time ranges from 1.5 weeks to 4 weeks, depending on the part’s geometry.

4. Simple and complex tooling structure with template mold base.

5. Process validation before production tooling.

6. High accuracy and consistent.

7. Material Flexibility and Design Adjustability.

8. Quick to- the market.

5. 3 years’ free store time and rapid injection mold tooling maintenance.

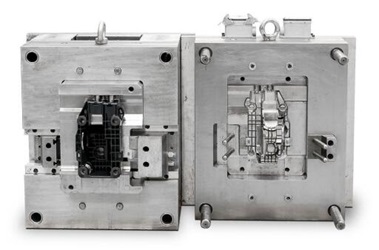

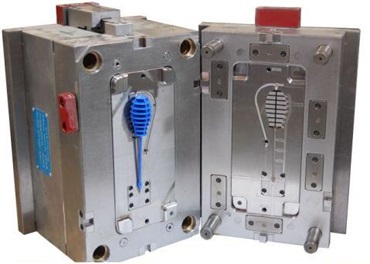

Rapid Production Tooling

Production Tooling is designed to make the end-product in high-volume manufacturing, it provides reliable, consistent, and cost-effective plastic parts production. It is the final step if the sales volume expand quickly, intended to delivery fully optimized molds for large-scale operations.

-

Key Features

1. Multiple cavities & hydraulic sliders.

1. Multiple cavities & hydraulic sliders.

2. Heated cores.

3. Optimized for volumes and automation friendly.

4. Tooling lead-time ranges from 4+ weeks, depending on the part’s geometry.

5. Long tooling lifetime with precision and stability molding.

6. Low part unit price at scale.

7. Extremely high efficiency by automation, 24 hours working.

8. Lifetime Rapid Production Tooling guarantee

Made in China: Development of China's Tooling and Die Industry

China has one of the largest tooling and die industry in the world nowadays, the industry has grown rapidly over the past 2 decades.Today, it encompasses more than 40,000 enterprises and employs over1 million skilled workers, producing a wide range of tools, dies, and molds for multiple industries. From simple sheet metal forming tools, injection molding molds, to die casting molds, China has strong capabilities now to serve both domestic demand and oversea markets. Our major export partners include Japan, South Korea, US, Germany, and India, reflecting China is a competitive tooling manufacturers in the world.

The key tooling production regions including Guangdong, Jiangsu, Shanghai, and Zhejiang, which cover around 80% of China’s tool making. The tooling business can’t grow so quick if without the Government support, especially through five-year industrial plans, has accelerated development. The advances in tooling technologies, CAD/CAM design, and CNC machining capabilities have enabled Chinese manufacturers to provide high-quality tools at competitive costs.Global clients can have high-quality standards tooling at low cost and short lead-time for prototype tooling, bridge tooling to mass production molds. China’s tooling and die industry continues to innovate and expand, reinforcing its role as a global hub for cost-effective, high-precision tooling solutions.

How to Find a Reliable Tooling Manufacturer in China

Finding tooling manufacturers in China is easy, but finding a reliable one is difficult. The key is when you know where to look.Start by researching online B2B platforms, company websites, and industry directories.Ask for referrals from industry peers and check client reviews to confirm reliability.Attend trade shows or request video tours to evaluate factories firsthand.Working with trusted partners, like TEAM RAPID, can also simplify the process by connecting you with verified manufacturers, ensuring quality, capability, and timely delivery for your projects.

A Guide of Tooling Costs

Size or material is not the only factor affecting on tooling cost, it is about part complexity, mold design, production volume, cosmetic requirements, and additional features as well. Understanding these factors, can help the buyers or designers why cost that much:

1.Mold Material

Aluminum mold is cheaper while it is quick to wear out. Steel mold is suitable for high-volume or long-term production while it is more expensive. At TEAM MFG, we use soft steel for prototype and low to medium-volume molds, the material cost is not expensive while durable.

2.Part Complexity & Design

Simple parts with less features cost less while complex parts increase design time, machining time and tooling structure costs.

3.Number of Cavities

The more cavities the more tooling costs. The more cavities the less unit part price. Same for the family mold.

4.Gate Types & Runner

Hot runner and complex gating systems increase tooling cost.5.Surface Finish

Polished, textured, or optical-grade surfaces require more precise machining and post-processing.Cosmetic-critical parts usually require hidden gates or high-precision molds.

6.Cooling System & Cycle Time

Advanced cooling channels reduce cycle time and improve part quality but increase mold complexity and cost.

7.Mold Structure

Side-actions, lifters, unscrewing cores, inserts, multi-shot or overmolding features increase tooling complexity and cost.

Typical Tooling Cost

Tooling Type

Purpose / Use

Material / Features

Typical Cost Range*

Prototype Tooling

For testing designs, functional prototypes, or low-volume production

Usually aluminum molds or soft steel; simple features, single-cavity; faster lead time

~$600 – $15,000

Bridge Tooling

For short-to-medium runs (hundreds to thousands of parts) before full production

May use soft or hardened steel; simple multi-cavity options; can incorporate some production features

~$2,000 – $20,000

Production Tooling

High-volume production, long-term use

Hardened steel; multi-cavity molds; durable components; may include hot-runner systems, sliders, lifters, inserts, or overmolding features

~$10,000 – $250,000+ depending on complexity and volume

*These are approximate ranges. Actual costs depend on part complexity, size, material, cosmetic requirements, gate design, number of cavities, and additional mold features.

Why Tooling at TEAM RAPID

TEAM RAPID offers one-stop tooling services, not only for production tooling, but also bridge tooling and even prototype tooling. We can help the clients to save the sourcing time at the very beginning from prototyping, also reducing the mistakes on bridge tooling and production tooling that met from prototype molds already. Beside from these, our advantages:

1. Reduce Risks

TEAM RAPID manages each project and ensures all customers' quality standards are met. Our high-quality vendors, experienced team, and quality control team ensure that a quality prototype tool/production mold is created.

2. Cost Saving

As China's tooling cost is between a 1/3rd and a 1/5th of western tools (prototyping tools may cost even less than 1/3rd in China), customers’ tooling costs are affected by their favor and production cost well.

3. Short lead times

Being in the tooling industry for over 10 years, our skillful team can make mold fast in short lead-time, prototype tooling can be as little as 7 days.

4. Quality

Our toolmakers can build prototyping tools and production molds which meet western quality standards without sacrificing the quality. Full inspection starts from IQC material checking to process quality control and OQC inspection.

Rapid Manufacturing at TEAM RAPID

Besides from tool making and injection molding services, TEAM RAPID offers a series of Rapid manufacturing services such as CNC machining, die casting, sheet metal fabrication, and rapid prototyping, we have:

1. Advanced Equipment

Precise production and inspection equipment with high stability.

2. Rich Experience

10+ years of experience in independent design, machining, rapid tooling, and injection molding capability.

3. High Quality, Competitive Price and Fast Delivery

Own the factory under systematic management, a professional team, and flexible production time to guarantee satisfying service.

4. One-stop Services

As one of the best rapid manufacturing companies, we support mold design & making, plastic injection production, machining, assembly, packing, delivery, and other services. We can provide strong engineering support to our customers; this dramatically reduces any potential quality risks that limit launching into the market quickly.

Our supports include the following:

- Product Design Assistance

- Design For Manufacturability (DFM)

- Mold Flow Service (MFA)

- Fully Detailed Mold Design low Analysis Service (MFA)

Check out the advantages of DFM and MFA

Just Need Injection Molded Parts – Tooling Can Stay Safely in Our Factory

Some of the oversea buyers, they just need injection molded parts for their products, they have no plan to buy injection machines or even build a molding shop for parts. That is OK to just purchase molding parts from us, we can take care of your tooling. TEAM RAPID can store your mold well in our factory for future production, we will clean, maintain, and protect your tooling after each run. Just easily send us your order, we will take care of the rest, the running batch of parts will shipped to you in time!This service saves you storage space, avoids shipping costs for heavy molds, and ensures fast turnaround for repeat production.

Our factory offers full-service injection molding and secure tooling storage, including:

- Dedicated mold storage rooms

- Strict quality and maintenance procedures

- Free or low-cost long-term storage

- Transparent ownership terms

- Fast turnaround for reorders

This ensures that once your mold is built, you enjoy stable, repeatable, cost-efficient production for years.

Exported Tooling – Build in China, ProduceLocally

For customers who want to run the production locally, TEAM RAPID provides a complete exported tooling service. Our molds can be built to international standards, fully meet the customer’s molding facilities in the USA, Europe, and other global regions.

Globally Used High -Quality Molds

TEAM RAPID uses certified mold steel, standard mold bases, and globally recognized components (HASCO, DME, MISUMI, etc.)to build the tool, we guarantee every exported tool is engineered for durability, repeatability, and ease of maintenance.All of these can be great supports for the customers to run the production smoothly locally.

Full Documentation Provided

To support seamless mold transfer, we supply complete documentation, including:

· 2D and 3D mold design files

· Component lists and steel certificates

· Mold trial reports and part measurement data

· Mold operation instructions

· Maintenance guidelines

· Spare parts list

These documents make it straightforward for your overseas production team to install, run, and maintain the mold.

Export Packaging and Protection

We take special care to prepare your tooling for long-distance transportation. Each mold is:

· Thoroughly cleaned and preserved with anti-rust treatment

· Secured with locking plates and safety bars

· Packed in strong export-approved wooden crates

· Labeled clearly for customs verification

· Protected with shock-absorbing materials

This ensures your mold arrives safely and ready for production.

Smooth Logistics and Global Shipping Support

We can arrange door-to-door, port-to-port, or air freight shipping, depending on your needs. Our team handles:

· Export documentation

· Customs clearance support

· Shipping coordination

· Delivery tracking

You receive your tooling quickly and without hassle.

Ready to Start Your China Tooling Project?

TEAM RAPID is a professional rapid tooling & mold manufacturing company in China. As one of the most successful rapid tooling companies, whether it is a simple mold or a complex mold, we can provide you with the best prototyping tools and production molds. Contact us today to learn more.

Get in Touch Today:

-

Email: [email protected]

-

Quote Request: Upload your 3D files (STEP, IGES, X_T, STL)

-

Support: One-to-one engineering assistance throughout your project

-

Lead Time: Fast DFM, rapid tooling build, and on-time delivery

Whether you are launching a new product or scaling up production, TEAM RAPID is ready to help you turn your ideas into high-quality parts—quickly and cost-effectively.

Tool Machining Cavity & Core Mold Trial Samples

Rapid Tooling Services — Frequently Asked Questions

Rapid tooling is one of tooling methods, it is fast-turnaround way to build a mold that can produce real injection-molded parts. Unlike traditional tooling methods, rapid tooling focuses on speed and affordability, making it ideal for early production, functional testing, and market trials.

Traditional molds are built for long-term, high-volume production and often require more time, harder materials, and bigger investment. Rapid tooling, on the other hand: · Shortens lead time · Uses cost-efficient materials · Supports faster design changes · Fits low- to mid-volume needs It allows you to move from prototype to real molded parts much sooner.

A few dozen to several thousand parts is the best volume for rapid tooling,. It’s designed to help companies validate design and enter the market without committing to a full production mold.