Insert Molding Solutions - High Production Efficiency

TEAM RAPID provides high-precision insert molding solutions to help customers create strong, durable, and cost-effective plastic parts. Insert molding is an advanced injection molding process where metal or other components are placed into the mold cavity and then encapsulated with molten plastic. This process combines multiple materials into a single, solid component — improving performance and reducing assembly costs.

TEAM RAPID provides high-precision insert molding solutions to help customers create strong, durable, and cost-effective plastic parts. Insert molding is an advanced injection molding process where metal or other components are placed into the mold cavity and then encapsulated with molten plastic. This process combines multiple materials into a single, solid component — improving performance and reducing assembly costs.

What Is Insert Molding

Insert molding is a specialized injection molding process that combines metal and plastic into a single, strong, and integrated component. During this process, pre-formed inserts — such as metal bushings, threaded studs, pins, or electrical contacts— are placed into a mold cavity before molten plastic is injected around them.

Once the plastic cools and solidifies, the insert becomes permanently encapsulated inside the molded part. This creates a durable bond between materials, improving the mechanical strength, accuracy, and overall functionality of the final product.

Insert molding is ideal for producing complex components that require metal reinforcement or embedded features, reducing secondary assembly steps and enhancing part reliability.

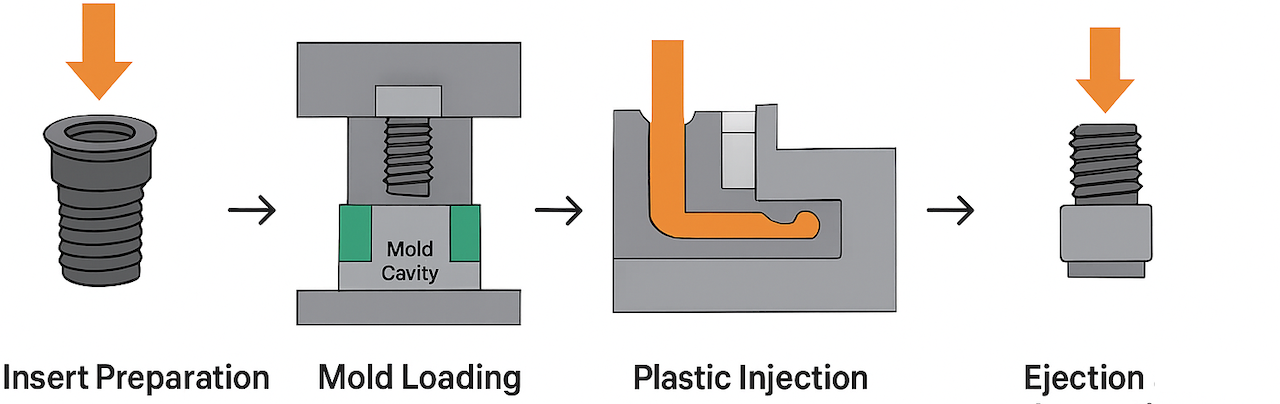

How Insert Molding Works

The insert molding process follows several key steps to ensure precision and consistency:

1. Insert Preparation

Metal or other inserts are cleaned and prepared to ensure strong adhesion between the insert and plastic material.

2. Mold Loading

The prepared inserts are manually or automatically placed into a specially designed mold cavity. The inserts are securely positioned using locating pins or magnetic fixtures.

3. Plastic Injection

Molten thermoplastic resin — such as ABS, Nylon, or Polycarbonate — is injected into the mold at high pressure. The plastic flows around the insert, filling the entire cavity.

4. Cooling and Solidification

As the part cools, the plastic hardens and tightly bonds with the insert, forming a single, integrated component.5. Ejection and Inspection

The finished part is ejected from the mold. Each piece is carefully inspected to ensure accurate insert placement, smooth surface finish, and reliable bonding.

Insert Molding Capabilities at TEAM RAPID

We specialize in a wide range of insert molding combinations and materials:

| Category | Capabilities |

|---|---|

| Insert Types | Threaded brass or stainless-steel inserts, electrical contacts, pins, bushings, clips, and custom hardware. |

| Material Options | Thermoplastics like ABS, PC, PP, Nylon, PBT, and metal inserts such as brass, aluminum, copper, and stainless steel. |

| Volume Range | From rapid prototypes to full-scale mass production. |

| Quality Control | Tight dimensional accuracy, strong bonding between materials, and repeatable production quality. |

Advantages of TEAM RAPID's Insert Molding Solutions

| Advantage | Description |

|---|---|

| Improved Strength and Durability | The insert and plastic are bonded into a single solid structure, delivering superior mechanical strength, higher load resistance, and long-lasting performance. |

| Reduced Assembly Costs | Insert molding eliminates secondary operations such as press-fitting or manual assembly, saving labor time and reducing overall production costs. |

| Enhanced Design Flexibility | Threaded inserts, pins, and electrical connectors can be integrated directly into molded parts, providing more functional and efficient component designs. |

| High Precision and Reliability | TEAM Rapid’s experienced engineers ensure accurate insert placement, optimized gating design, and stable molding parameters to achieve tight tolerances and defect-free results. |

| Scalable Production | From low-volume prototyping to high-volume manufacturing, TEAM Rapid offers flexible insert molding solutions with manual, semi-automatic, or automated insert loading options. |

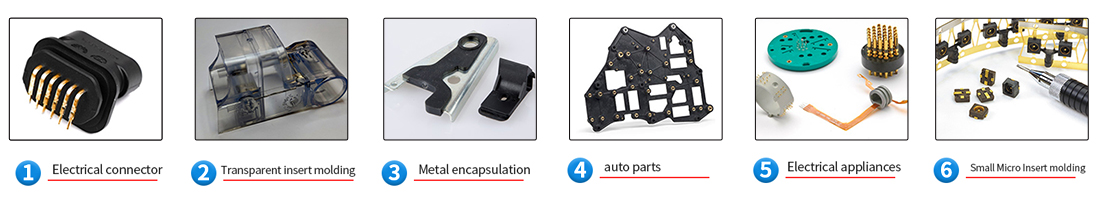

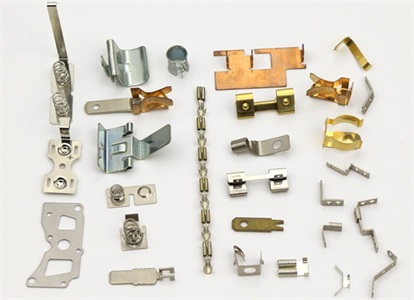

Types of Molding Inserts

Most commonly, the purpose of insert injection molding is to fasten and locate plastic parts with other assemblies by inserts. It is also common to have different kinds of inserts in one single injection molded part. The following is a list of some most common types of inserts. As one of the expert insert molding manufacturers, TEAM Rapid offers to insert injection molding service and CNC machining service to make your metal insert molding parts fast and cost-effectively. The common types of injection molding inserts used at TEAM RAPID:

Most commonly, the purpose of insert injection molding is to fasten and locate plastic parts with other assemblies by inserts. It is also common to have different kinds of inserts in one single injection molded part. The following is a list of some most common types of inserts. As one of the expert insert molding manufacturers, TEAM Rapid offers to insert injection molding service and CNC machining service to make your metal insert molding parts fast and cost-effectively. The common types of injection molding inserts used at TEAM RAPID:

1, Male Threads insert

2, Female Threads insert

3, Dowel Pins insert

4, Spring-Loaded Clips insert

5, Electrical Contacts insert

Commonly Used Plastics for Insert Molding

Selecting the right plastic resin is critical for achieving strong bonding, durability, and high-quality insert-molded parts. At TEAM RAPID, we work with a wide range of engineering-grade thermoplastics that offer excellent mechanical strength, heat resistance, and dimensional stability.

Below are some of the most commonly used plastics for insert molding:

| Material | Key Features | Typical Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Strong, tough, and easy to mold; excellent surface finish and dimensional stability. | Consumer products, automotive components, and enclosures. |

| PC (Polycarbonate) | High impact resistance, optical clarity, and heat resistance; ideal for durable parts. | Electronic housings, lighting components, and lenses. |

| Nylon (PA6, PA66) | Excellent wear resistance, toughness, and fatigue strength; compatible with metal inserts. | Gears, bushings, and mechanical assemblies. |

| PBT (Polybutylene Terephthalate) | Superior electrical insulation, low moisture absorption, and dimensional stability. | Connectors, switches, and automotive electronics. |

| PP (Polypropylene) | Lightweight, chemical-resistant, and cost-effective; good for high-volume production. | Consumer goods, packaging, and industrial parts. |

| PEEK (Polyether Ether Ketone) | Exceptional mechanical and thermal performance; withstands extreme conditions. | Aerospace, medical, and high-performance industrial applications. |

Choosing the Right Plastic for Insert Molding

When selecting plastic materials for insert molding, our engineers consider:

1. Thermal compatibility between the insert and plastic.2. Mechanical performance required by the final product.

3. Chemical and environmental resistance needed for long-term use.

4. Surface finish and color requirements for aesthetic or branding needs.

Our team at TEAM RAPID will help you choose the best plastic resin for your project to ensure excellent bonding, durability, and overall performance.

Design & Manufacturing Considerations for Insert Molding

Achieving high-quality insert molded parts requires careful design and manufacturing planning. At TEAM RAPID, our engineering team focuses on every detail — from material selection to mold design — to ensure precision, consistency, and superior bonding between inserts and plastic resins. Below are key factors to consider when designing and manufacturing insert molded components:

1. Insert Design and Geometry

The insert’s shape, surface texture, and retention features are critical for strong bonding. Inserts can include knurled surfaces, undercuts, grooves, or holes that allow the molten plastic to grip securely. Proper design prevents insert movement or pull-out during use and enhances long-term part durability.

2. Material Compatibility

For successful insert molding, the insert material(typically metal) and plastic resin must be thermally and mechanically compatible.

Our engineers evaluate factors such as:

2. Bonding strength and adhesion under molding temperatures

3. Environmental and chemical resistance required for the application

TEAM RAPID works with a wide range of engineering plastics such as ABS, PC, Nylon, PBT, and PEEK, paired with inserts made from brass, stainless steel, aluminum, and copper.

3. Mold Design Optimization

A well-designed mold is essential to keep the inserts stable and achieve consistent molding quality. Our mold designers focus on:

1. Accurate insert positioning using locating pins or magnetic fixtures

2. Proper gate and vent placement to ensure smooth plastic flow around inserts

3. Efficient cooling channel design to reduce cycle time and improve part uniformity

4. Durable mold construction to handle repeated insert loading cycles

4. Insert Loading Method

Depending on production volume and part complexity, insert loading can be:

1. Manual loading for low-volume or rapid prototyping production.

2. Semi-automatic loading using fixtures for mid-volume runs.

3. Fully automated insert placement for high-volume manufacturing.

TEAM RAPID offers flexible solutions to meet your cost, speed, and precision requirements.

5. Process Control and Quality Assurance

We apply tight process control to maintain consistent molding conditions. This includes monitoring injection pressure, temperature, cooling time, and cycle speed. Every insert-molded part under goes dimensional inspection and bond strength testing to ensure it meets design specifications and functional requirements.

Why TEAM RAPID for Insert Molding Design & Manufacturing?

With years of experience in injection molding and rapid tooling, TEAM RAPID provides:

1. Expert DFM (Design for Manufacturability)analysis before production.

2. Fast and accurate prototype mold development.

3. Scalable solutions from small batch runs to mass production.

4. Commitment to delivering high-quality, cost-effective insert molded parts for customers worldwide.

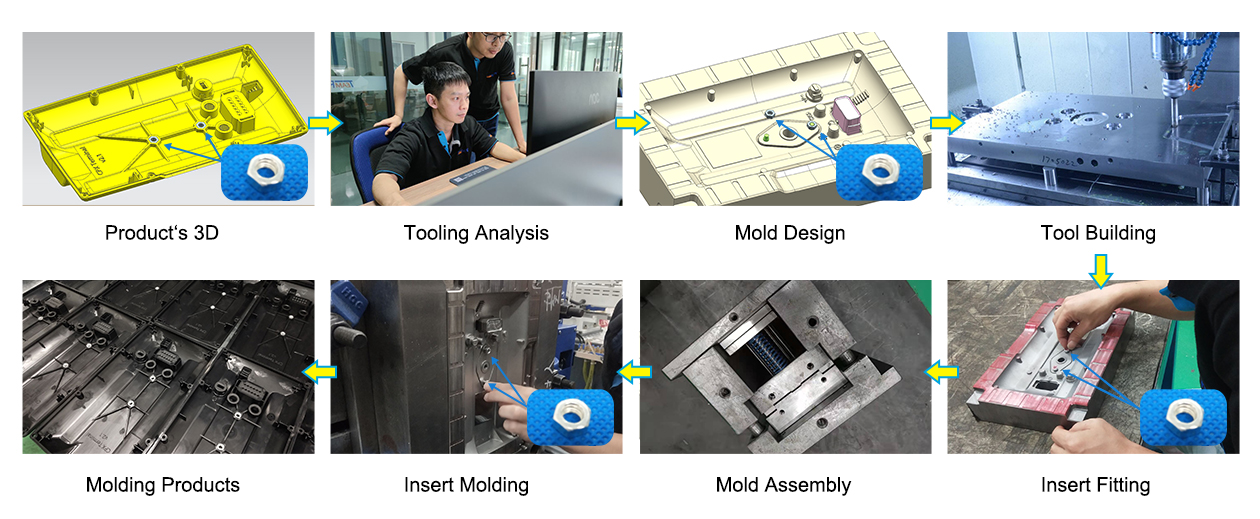

Electronic Black Cover Insert Molding Case Working Flow

Get Your Insert Molding Quote Today

Looking for reliable insert molding manufacturers to bring your design to life?

Contact TEAM RAPID today to discuss your project requirements.

Our engineering team will help you choose the right materials, optimize your mold design, and deliver high-quality insert molded parts that meet your performance and budget goals.

Request a Free Quote or email us at sales@teamrapidtooling.com today!

Frequently Asked Questions

What Is Insert Molding?

In injection molding, insert molding is a process that involves inserting components into a mold to create plastic parts with an insert. This step helps create the finished product that needs one or more inserts. Typically, components made of materials with different properties are used in insert molding. For instance, a brass fastener can be molded into a soft material to be used as a bearing surface.

What Is the Difference between Insert Molding and Overmolding?

Insert molding and overmolding are two subsets of the manufacturing procedure known as injection molding. While they share the same process, they have distinct characteristics.

One of the fundamental differences between overmolding and insert molding is that the latter is not bounded by plastic. In overmolding, the process is utilized to create products usually made for shelf appeal. On the other hand, in insert molding, the process is used to create rigid products.