Overmolding - Full Technologies to Meet Your Needs

What is Overmolding

Overmolding, a unique marvel in production and rapid manufacturing, involves the fusion of two or more distinct materials to craft a singular, multifaceted component. This intricate process typically unfolds by molding a robust plastic part, followed by the application of a supple material, resulting in a seamless final product.

Development of Overmolding

Delving into the annals of manufacturing history, the concept of overmolding has traversed several decades, undergoing a metamorphosis spurred by advancements in both materials and technology. In its nascent stages, overmolding found its footing in the fabrication of rigid rubber articles and the soles of footwear. However, the transformative arrival of thermoplastic elastomers in the 1960s bestowed newfound versatility and cost-effectiveness upon the process. In the contemporary landscape, overmolding has transcended its origins, finding applications across diverse industries such as automotive, medical, electronics, and consumer goods. It has become the linchpin for crafting products endowed with intricate geometries and elevated performance attributes. The evolution of over-molding points towards a promising future as relentless research and development continues to push the boundaries of materials and plastic molding technologies. As we navigate the intricate world of overmolding, we uncover not just a manufacturing technique but a narrative of innovation, adaptability, and boundless possibilities.

Overmolding Process - How Does Overmolding Work

This process can be automated for high-volume production or customized for low-volume prototyping — depending on your project’s needs.

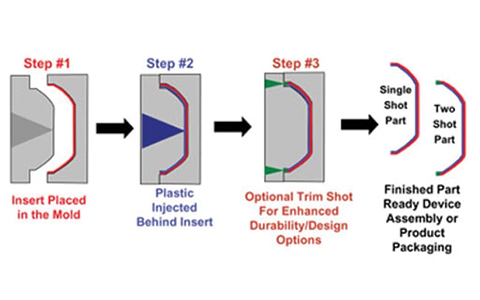

The overmolding process typically follows these key steps:

1. Preparation of the Substrate

The base component — either a pre-molded plastic part or a metal insert — is cleaned and prepared to ensure proper adhesion between layers.2. Mold Setup

The substrate is placed into a specially designed overmold tool that fits precisely around it. The mold cavity is engineered to accommodate the additional layer.3. Injection of Overmold Material

A molten secondary material (such as TPE or TPU) is injected over the substrate under high pressure. The material flows into the mold cavity and bonds to the surface of the base part.4. Cooling and Solidification

The part is cooled in the mold to allow the materials to bond completely and achieve dimensional stability.5. Ejection and Finishing

Once cooled, the completed overmolded part is ejected and may undergo secondary finishing such as trimming, inspection, or surface treatment.

Types of Overmolding & Comparison

The overmolding process can be performed in several ways depending on the materials used, production volume, and design requirements. Each method offers unique advantages for product performance and cost efficiency. Below are the most common types of overmolding techniques used in modern manufacturing:

| Overmolding Type | Description | Key Benefits | Common Applications |

|---|---|---|---|

| Two-Shot (2K) Overmolding | Both substrate and overmold are produced in a single automated cycle using two injection units. | Strong bonding, high precision, ideal for high-volume production. | Automotive parts, medical devices, consumer electronics. |

| Insert Overmolding | A pre-molded plastic or metal insert is placed into the mold before injecting the overmold material. | Cost-effective, flexible for low-to-medium production, supports various materials. | Connectors, hand tools, electronic housings, grips. |

| Co-Injection Molding | Two materials are injected simultaneously to form a core–shell structure. | Excellent strength, lightweight, reduces material waste. | Automotive interiors, packaging, consumer products. |

| Multiple Material Overmolding | Involves more than two materials to form complex, multifunctional parts. | Combines multiple functions, reduces assembly, enhances design flexibility. | Wearable devices, industrial components, advanced electronics. |

Overmolding Materials – Base and Overmold Material Selection

Choosing the right overmolding materials is key to achieving excellent bonding strength, part durability, and appearance. In the overmolding process, two types of materials are used — the base (substrate)and the overmold (secondary material). Each must be selected carefully to ensure compatibility and performance.

1. Base Materials (Substrate Materials)

The base material forms the main structural body of the part. It is usually a rigid plastic or metal designed to provide strength, stiffness, and dimensional stability. The base material must withstand the heat and pressure of the overmolding process and allow good adhesion with the secondary material.

| Overmold Material | Key Properties | Typical Applications |

|---|---|---|

| TPE (Thermoplastic Elastomer) | Soft touch, excellent flexibility, and chemical resistance | Grips, seals, consumer products |

| TPR (Thermoplastic Rubber) | Rubber-like feel with easy processing | Tool handles, grips, overmolded buttons |

| TPU (Thermoplastic Polyurethane) | High abrasion resistance and elasticity | Protective cases, industrial seals, wear parts |

| Silicone Rubber | Excellent temperature resistance and flexibility | Medical devices, waterproof seals, wearable electronics |

| Santoprene? (TPV – Thermoplastic Vulcanizate) | Combines elasticity of rubber and processability of thermoplastics | Automotive weather seals, soft grips |

| PVC (Polyvinyl Chloride) | Cost-effective, flexible, and good chemical resistance | Cable insulation, grips, protective coatings |

Tip:When selecting a substrate, ensure its melting point is higher than the overmold material to avoid deformation or weak bonding during injection.

2. Overmold Materials (Secondary or Soft Materials)

The overmold material is applied over the base substrate to provide grip, sealing, shock absorption, and improved ergonomics. These materials are usually soft, flexible, and elastic — such as thermoplastic elastomers (TPEs) or silicones.

| Overmold Material | Key Properties | Typical Applications |

|---|---|---|

| TPE (Thermoplastic Elastomer) | Soft touch, excellent flexibility, and chemical resistance | Grips, seals, consumer products |

| TPR (Thermoplastic Rubber) | Rubber-like feel with easy processing | Tool handles, grips, overmolded buttons |

| TPU (Thermoplastic Polyurethane) | High abrasion resistance and elasticity | Protective cases, industrial seals, wear parts |

| Silicone Rubber | Excellent temperature resistance and flexibility | Medical devices, waterproof seals, wearable electronics |

| Santoprene? (TPV – Thermoplastic Vulcanizate) | Combines elasticity of rubber and processability of thermoplastics | Automotive weather seals, soft grips |

| PVC (Polyvinyl Chloride) | Cost-effective, flexible, and good chemical resistance | Cable insulation, grips, protective coatings |

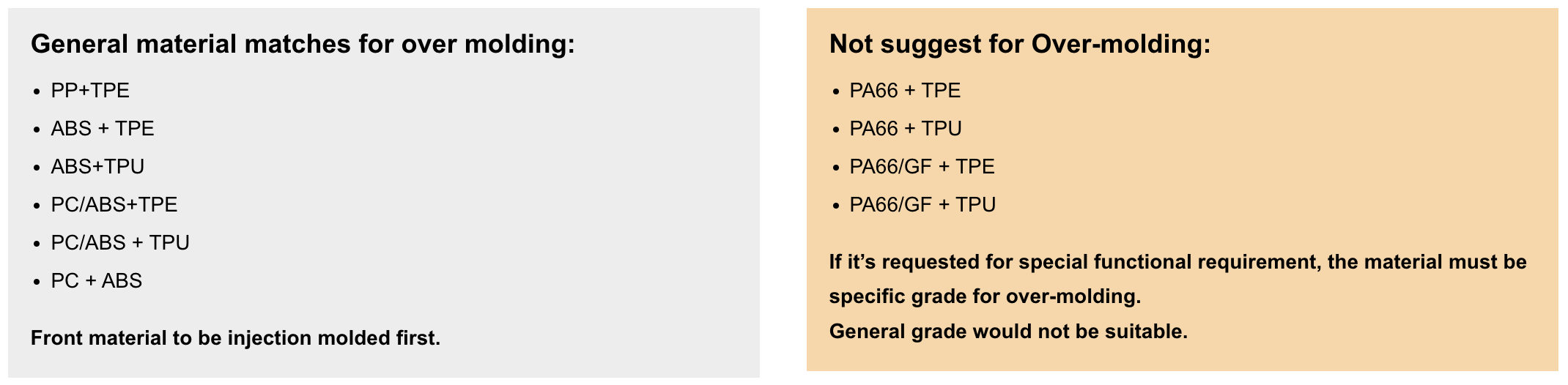

3. Common Material Combinations for Overmolding

| Base Material | Overmold Material | Compatibility & Notes |

|---|---|---|

| ABS | TPE / TPU | Excellent bonding; ideal for grips and handheld devices |

| PC | TPE | Good adhesion; often used for transparent or impact-resistant parts |

| Nylon (PA) | TPU | Works well if moisture-controlled; ideal for mechanical components |

| PBT | TPE | Requires adhesion promoter or primer; used for electrical parts |

| Aluminum | Silicone / TPE | Used in insert overmolding with mechanical interlock features |

| Stainless Steel | TPE / TPU | Needs surface texturing or plasma treatment for bonding |

4. How to Choose the Right Overmolding Material

When selecting materials for overmolding, consider:

Bonding Compatibility– Ensure thermal and chemical compatibility between substrate and overmold.

End-Use Environment– Consider exposure to heat, UV, chemicals, and mechanical stress.

Aesthetic and Tactile Requirements– Choose materials that deliver desired surface feel, color, and finish.

Cost and Production Volume– Some materials are more cost-effective for high-volume runs.

Regulatory Compliance– For medical or food-contact products, use FDA- or RoHS-approved materials.

Engineering Tips for Overmolding Process

The success of any overmolding project depends on smart engineering decisions. Proper material selection, part design, and molding process control are critical to achieving strong bonding, perfect surface finish, and cost-effective production. Here are expert overmolding engineering tips from TEAM RAPID’s experienced manufacturing engineers.

1. Select Compatible Materials for Overmolding

Selecting the right combination of base material and overmold material ensures strong adhesion and consistent quality.

-

Match melting temperatures and shrinkage rates to avoid deformation.

-

When chemical bonding is weak, use mechanical interlocks such as undercuts, ribs, or grooves.

-

Test bonding performance with small-batch prototypes before scaling to production.

Popular material combinations:

-

ABS + TPE→ Excellent chemical bonding and soft-touch feel

-

PC + TPU→ Great impact strength and transparency

-

Nylon + TPE→ Requires drying and process control for stable adhesion

-

Metal + TPE/Silicone→ Use surface texture or primer for mechanical grip

2. Optimize Part Design for Overmolding

A well-designed part ensures stable molding and consistent bonding quality.

-

Maintain uniform wall thickness to prevent warpage or sink marks.

-

Add1–3° draft angles for easier ejection.

-

Avoid sharp edges and sudden transitions between layers.

-

Include venting features to remove trapped air and prevent short shots.

-

Define bonding zones clearly in the CAD design.

Engineering Tip:Early design review with your overmolding manufacturer helps identify potential issues before tooling, saving cost and lead time.

3. Control Key Molding Parameters

Precise control of molding parameters determines the final part quality.

| Parameter | Engineering Guideline | Result |

|---|---|---|

| Injection Temperature | Adjust close to melt point without degradation | Stable flow & bonding |

| Injection Pressure | Enough to fill cavity fully, avoid flashing | Uniform density |

| Mold Temperature | Keep consistent across cycles | Prevents delamination |

| Cooling Time | Allow sufficient cooling for both layers | Reduces warpage |

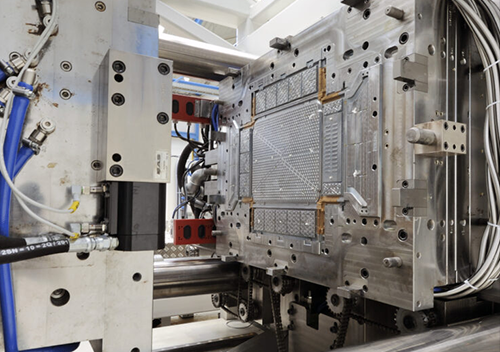

4. Overmolding Mold Design Recommendations

A precision-built mold is the foundation of successful overmolding.

A precision-built mold is the foundation of successful overmolding.

-

Choose two-shot molds for large volume or insert molds for flexible low-volume production.

-

Ensure accurate alignment of mold halves to prevent flashing.

-

Optimize gate locations to reduce visible weld lines.

-

Use balanced runner design for uniform filling.

-

Add air vents at bonding zones to improve adhesion and appearance.

Pro Tip: Use mold flow simulation software to predict filling and cooling behavior before steel cutting.

5. Surface Preparation and Pre-Treatment

Proper surface preparation ensures long-lasting bonding between materials.

-

Keep the substrateclean, dry, and oil-free.

-

Useplasma, flame, or corona treatmentto increase surface energy.

-

Formetal inserts, applysandblasting or chemical etchingto promote adhesion.

-

Dry hygroscopic plastics (like Nylon or PBT) before molding to remove moisture

6. Quality Inspection and Process Validation

Consistent quality control keeps overmolded parts reliable and defect-free.

-

Adhesion test:Check bonding strength using peel or pull tests.

-

Visual inspection:Detect warpage, delamination, or surface defects.

-

Dimensional measurement:Verify tolerances and shrinkage.

-

Process stability check:Maintain repeatable cycle parameters for consistent results.

7. Partner with Experienced Overmolding Engineers

Collaborating early with your overmolding manufacturer ensures the best results.

At TEAM RAPID, our engineering team supports you through every stage — from design optimization and material selection to tooling design and mass production validation. We help customers in theUSA and Europe achieve high-performance overmolded components with short lead times and cost-effective solutions.

Advantages and Disadvantages of Overmolding

When deployed properly, overmolding is a powerful technique for achieving high-performance parts with integrated materials, improved ergonomics, and strong aesthetics—especially in markets such as the USA and Europe. However, it's essential to evaluate tooling investment, material compatibility, and design requirements carefully to ensure the approach is the most cost-effective solution for your specific production volume and product goals.

When deployed properly, overmolding is a powerful technique for achieving high-performance parts with integrated materials, improved ergonomics, and strong aesthetics—especially in markets such as the USA and Europe. However, it's essential to evaluate tooling investment, material compatibility, and design requirements carefully to ensure the approach is the most cost-effective solution for your specific production volume and product goals.

-

Advantages of Overmolding

Overmolding is a manufacturing technique where two or more materials are bonded in a single part to deliver enhanced functionality, feel, and aesthetics. Here are the key benefits:

Integrated Functionality & Reduced Assembly

Overmolding blends multiple materials in one component—reducing the need for separate parts or post-assembly steps. This means fewer joins, faster assembly, and lower labor costs.Improved Product Performance

By combining a rigid substrate (such as PC/ABS) with a soft touch material (such as TPE or silicone), you can achieve vibration/impact damping, enhanced grip and ergonomics, electrical insulation, and better resistance to chemicals or UV.Enhanced Aesthetics & User Experience

Overmolding allows use of soft‐touch exterior surfaces, multiple materials or colors in a single part, and seamless transitions between surfaces—helping your product stand out on shelves in Europe and the USA.Cost-Effective Production for Many Volumes

With mature tooling and automation, overmolding can offer cost-effective production even for moderate volumes. Leveraging one combined component rather than multiple parts can reduce overall production cost and risk.

-

Disadvantages of Overmolding

While overmolding offers strong benefits, it also brings design and production considerations.

Higher Initial Tooling & Equipment Investment

The process often requires specialized molds or two-shot injection machines, which raises upfront cost. This makes the economics less favorable for very small production runs.Material Compatibility Constraints

Successful overmolding depends on substrate and over-mold materials bonding reliably. Materials must have compatible melt temperatures, chemical affinities, and shrinkage rates—otherwise defects like delamination or peeling may occur.Design & Manufacturing Complexity

Overmolding demands careful attention to part geometry, wall-thickness, draft angles, and bonding zones. Undercuts, sharp corners, uneven wall thicknesses, or poor mold design can lead to issues like short shots, flash, warpage, or incomplete bonding.Cost-Effectiveness May Drop at Very Low Volumes

When production volumes are very low, the tooling and setup costs of overmolding may outweigh the benefits, making simpler molding or assembly methods more economical.

Applications of Overmolding: Elevating Industries through Versatility

The multifaceted prowess of overmolding permeates a spectrum of industries, bestowing upon products an amalgamation of versatility and heightened functionality.

-

Automotive Industry

In the automotive sector, overmolding takes center stage, fashioning controls and handles with soft-touch grips, concurrently offering insulation for intricate wiring. Within the automotive realm, over-molding births components like seals, gaskets, and controls, where the soft-touch allure meets enhanced practicality.

-

Medical Industry

The medical landscape witnessed the ergonomic revolution brought about by over-molding, gracing surgical tools with comfortable handles, and encapsulating electronic components in medical devices. The medical tapestry showcases over-molded marvels, from surgical instruments donning ergonomic handles to medical devices encapsulating sophisticated electronics.

-

Consumer Industry

in the consumer electronics arena, over-molding crafts housings with tactile finesse ensures a comfortable grip while safeguarding delicate electronics from environmental influences. Smartphones, tablets, and wearable devices embrace over-molding, adorning their housings for an ergonomic grip and elevated comfort.

-

Instrument

The instrumental role of overmolding extends to power tools, wherein handles undergo over-molding for an augmented grip and heightened comfort, while sports enthusiasts encounter its impact in golf clubs and racquets featuring over-molded grips, elevating the arena of performance.

In these examples, overmolding transcends its role as a manufacturing process, emerging as the architect of innovation, reshaping products across diverse industries.

Overmolding vs. Insert Molding – What’s the Difference and Which Is Right for Your Project?

When developing custom plastic or rubber parts, understanding the difference between overmolding and insert molding helps you choose the best manufacturing method for your design, budget, and performance requirements. Both processes combine two materials into one part, but they differ in how the materials are joined and when the insert is added.

| Aspect | Overmolding | Insert Molding |

|---|---|---|

| Process | Molding one material over another pre-molded substrate | Injecting plastic around a metal or other pre-placed insert |

| Materials | Typically soft TPE/TPU over rigid plastic | Plastic with metal or other rigid inserts |

| Purpose | Improves comfort, grip, or aesthetics | Adds strength, functionality, or conductivity |

| Applications | Handles, grips, wearable devices | Connectors, housings, fasteners |

| Cost | Higher due to multi-step molding | Cost-effective for metal-plastic parts |

| Best For | Multi-material, ergonomic parts | Integrated assemblies with metal inserts |

Which Process Should You Choose

-

Choose overmolding if your part requires comfort, sealing, or improved user feel.

-

Choose insert molding if your part needs strength, electrical contact, or metal reinforcement.

Not sure which method fits your project? Our engineering experts at TEAM RAPID can help you evaluate material compatibility, bonding performance, and production cost to ensure the most efficient solution.

Overmolding Prototyping Methods at TEAM RAPID

At TEAM RAPID, we provide vacuum casting and soft tooling methods to help customers test their overmolded parts efficiently and cost-effectively.

1. Vacuum Casting (Urethane Casting for Overmolding Prototypes)

Vacuum casting is a cost-effective and flexible method to create overmolding-like prototypes using silicone molds and polyurethane (PU) materials. It can simulate both rigid and soft components to achieve an overmolded look and feel without building metal tooling.

How it works:

-

A master model (CNC or 3D printed) is made.

-

A silicone mold is created around the master.

-

PU materials are cast under vacuum to form both layers — rigid and soft.

Advantages:

-

Low cost and quick lead time (5–10 days)

-

Excellent for visual and ergonomic evaluation

-

Ideal for small batches (10–50 parts)

Best for:Early-stage design validation, appearance models, and functional testing before hard tooling.

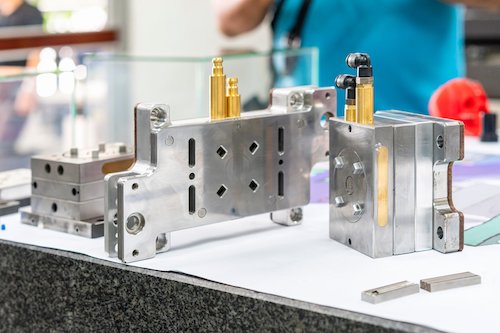

2. Soft Tooling (Rapid Tooling)

Rapid tooling uses aluminum or soft steel molds to replicate real injection molding conditions. It enables you to test fit, bonding performance, and visual quality using production-grade materials.

Rapid tooling uses aluminum or soft steel molds to replicate real injection molding conditions. It enables you to test fit, bonding performance, and visual quality using production-grade materials.

Advantages:

-

Fast turnaround (typically 7–15 days)

-

Real material validation under production conditions

-

Cost-effective for small-volume runs

Best for:10–200 prototypes, functional testing, and design verification.

Why Choose Our Overmolding Services

1. Complete In-House Solution

1. Complete In-House Solution

We handle every step of the overmolding process — from design and tooling to production and inspection. Working with one trusted supplier saves you time, cost, and communication hassle.

2. Professional Engineering & Material Options

Our engineers have decades of experience in injection and overmolding. We work with TPE, TPU, silicone, PC/ABS, nylon, and more — ensuring strong bonding, smooth finish, and long-lasting performance.

3. Consistent Quality for Global Markets

We follow strict process control and quality inspection to meet USA and Europe standards. Each part is durable, precise, and ready for your market requirements.

4. Cost-Effective for Any Volume

Whether you need low-volume prototypes or mass production, we offer flexible overmolding solutions with competitive pricing and fast turnaround.

5. Design and Technical Support

Our team helps optimize your part design for overmolding — from material selection to mold structure — to achieve the best look, performance, and manufacturability.

6. Trusted Supplier for Multiple Industries

We serve automotive, medical, consumer, and industrial sectors. From soft-touch grips to functional seals, we deliver reliable overmolded parts that fit your needs.

Frequently Asked Questions

What is Overmolding?(What is Plastic Overmolding?)

Overmolding is a process that involves combining multiple materials to create a single part. This process, which is usually performed in a mold, involves the insertion of a wire and a connector into a mold. The first material covered by this process is the substrate, while the other materials are used to cover the other components. The over-molded part can be either a rigid plastic component or an overlay layer of a TPU. There are two overmolded components: the insert molding technique and the multiple-shot method.

An over-molded cable is a type of full assembly consisting of a wire and a connector combined into one seamless part. The process begins by placing the cable assembly inside a mold. After the plastic material melts, it solidifies and conforms to the mold's shape. This then seals the junction point of the wire and the connector.

How does Overmolding Work?

In the manufacturing industry, overmolding is a widely used process. One of the most common types of this process is multiple-material molding. Multiple-material mold is also known as 2K or Two-Shot molding. This process involves creating a bond between over-molded parts and a substrate. The multiple material molding processes involve creating two sets of cavities, known as cavities 1 and 2. The first holds the substrate, while the other molds the over-molded component. This process is commonly used to produce various products, such as flexible components and industrial equipment. This technique has various advantages, such as superior part quality and low cycle time.

Multiple Material Molding Options:

Elastomer over Thermoplastic Substrate

Thermoplastic over Thermoplastic Substrate

Multiple Material Molding Steps:

Step 1: Mold the parts that need to be over-molded.

Step 2: Put the molded parts into cavity 2.

Step 3: The injected molten plastic is cooled, followed by the separation of the core and cavities.

Step 4: In this step, the mold is closed, and the molten plastic is injected into cavity 2.

Step 5: After cooling, the material, the part, is ejected from the injection mold.

What is Overmolding in Injection Molding?

Overmolding is one of the important parts of the injection molding process. In addition to creating a single part, overmolding involves combining two different materials. This process is usually performed in two shots. The first shot is usually made from more rigid plastic. The second shot, called the over mold, is made from a more flexible plastic-like material. Through overmolding, product designers can create functional and beautiful components by combining two different plastic materials.

What is Overmolding Process?

The materials can be very different in the overmolding process, which involves creating a single component from the combination of several materials. Understanding the various materials used in the overmolding process is very important. The two main categories of these are the substrate and the overmold.

substrate and overmold

The over-mold is molded onto a substrate, while the base material is the substrate. Depending on the end product and the manufacturer's creativity, there are typically two or more over-molded components.

What is the Difference between Insert Molding and Overmolding?

Overmolding and insert molding are structural differences. The former involves the creation of a base or substrate inside a mold, while the latter involves the addition of a layer to enclose it. The most common process in this mold is adding plastic components to a metal part, such as a screwdriver.

What Files to Send for Cable Overmolding?

We need the STEP or IGS format 3D files of your products. Our engineers will suggest the available proposals according to your design and demanded quantities. The vacuum casting process makes your over-molding prototypes or rapid tooling for over-molding small-volume prototypes.

What is Overmolding? How to Design It?

Mechanical Interlock

Overmolding follows the same principles as traditional injection molding processes but a few additional quirks in design:

1. Proper draft angles and uniform wall thickness with smooth transition lines maintained in both parts.

2. The wall thickness of over-molding areas should be equal to or less than that of the substrate below.

3. The overmolding materials should in lower melting temperature than the substrate.

4. Mechanical interlocks can be used to repair practical chemical bonding.

5. Texturing on the substrate part can help with adhesion.

Have no idea about insert molding vs. overmolding? Contact us for more design tips for your project today. Our engineer will tell you the differences between insert molding vs. overmolding and give you the best selection!