Our 5 Top Key Points for Mold Design in 2024

Injection molding, a pivotal manufacturing process, is widely applied across diverse industries, from automotive to medical. Injection molding process involves injecting molten material into molds, resulting in parts of various shapes and sizes. The design of the injection mold holds paramount importance, directly influencing the quality and efficiency of the final product. This method ensures precision, consistency, and cost-effectiveness, making it indispensable in numerous industries in 2024. Understanding its intricacies is imperative for anyone venturing into the realm of rapid manufacturing.

Understanding the Basics of Injection Molding

Injection molding, a versatile process, creates custom plastic parts by injecting molten material into a precisely crafted mold. The procedure commences with plastic granules being fed into a heated barrel. These granules undergo melting and amalgamation through a reciprocating screw. Subsequently, the molten plastic is injected into a cooled mold cavity, where it solidifies into the desired form. Once the part cools and hardens, it is ejected from the mold, finalizing the process.

The design of the injection mold stands as a pivotal element in this process. It dictates the part's dimensions, structural integrity, and performance attributes. A meticulously devised mold ensures the production of high-caliber parts that meet exacting specifications. Additionally, it optimizes the molding process by minimizing waste and curtailing cycle times.

When crafting an injection mold, a multitude of considerations come into play. These encompass the choice of plastic material, the envisaged shape and size of the part, and specific molding requisites like cooling duration and ejection mechanism. The mold's blueprint must also accommodate subsequent post-molding operations, such as finishing or assembly.

A profound comprehension of injection molding fundamentals and the pivotal role of mold design is imperative for individuals engaged in the manufacturing domain. This knowledge not only guarantees the fabrication of top-tier parts but also contributes significantly to the overall efficacy and profitability of the manufacturing endeavor.

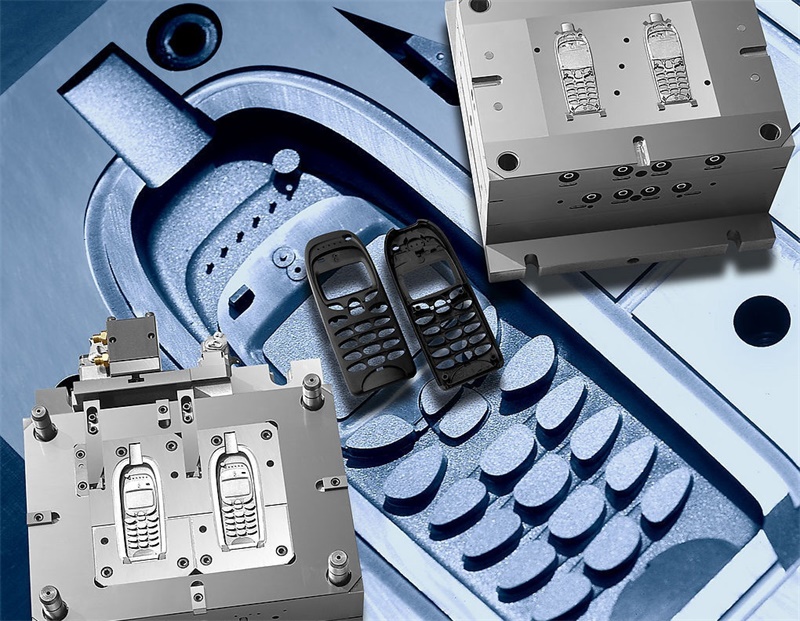

How to make a mold for plastic? Are you working on a new injection molding project? You might have some concepts about how to design and manufacture your products. To ensure you can get high quality parts in short time frame, we would like to share our 5 important points about mold design that may help you to kick off your Rapid Prototype Tooling and injection molding project.

The Top 5 Key Points of Mold Design

1. Layout, layout, Layout

Layout is one of the critical aspects in Mold Design, it relates on how we set the injection point, parting lines and ejection system etc. When you send us your initial 3D model, our experienced engineers use mature techniques to stimulate and define how to layout your part in the mold. Some parts in same or closed size, we would suggest making a family mold. In that case, the tooling cost can be cut down without compromising the quality.

2. Process: optimal process always helps to get high quality injection mold parts.

Gate Type

Direct gate, Side gate, Sub gate, Tunnel Gate, Pin Gate are some common gates in injection field. Part size, injected material, part structure has strong relationship of choosing which gate typ. Meanwhile, we need to bear in mind that remove of the gate also leaves a small “scar” on the part, how to minimize and hide this scar is one of considerations. Proper Gate can shorten the injection cycle time and mold parts quickly.

Shrinkage

Shrinkage on different material is differ, set the mold shrinkage according to material’s properties. Due to some part may have quite uneven wall thickness, adjust shrinkage partially is necessary sometime.

Parting line

parting line should be connected smoothly, try the best to avoid sharp corner and avoid going through the visible surfaces.

Cooling

The purpose of setting cooling system (water lines, cooling well, beryllium copper cooling) is to bring down the mold temperature and raise the production efficiency.

Ejection

Please bear in mind that ejection marks can be seen if you mold the part in transparent, you need to set the ejection skillfully and choose the best ejection way (ejector pin, ejector block, striper etc.) for your molded part.

Hereby, DFM (Design for Manufacturability) is necessary for figuring out all the potential issues before cutting the steel.

3. Mold Steel

Al 7075, P20, S136, NAK80 are some popular tool steels in China. They have different properties, S136 & NAK80 are recommended as polishing steel for high gloss parts.

Typically, mold in P20, S136, NAK80 steel can perform longer lifetime, mold maker will base on your rough required quantity and part finish to suggest the best tool steel.

4. Draft & Texture

Draft allows the plastic parts to be ejected successfully. Typically, 0.5~1-degree draft angle is enough for gloss finish parts. For texture finish part, the roughness of texture affects the big or small draft, the draft degree can be known by reading texture code book. If design and assembly permission, the bigger draft is better. Draft marks happen on injection molding mold parts if without proper or in small draft, the lifetime of mold will be shortened by repeated wearing.

5. Injected Materials

Injected material has strong relationship with mold shrinkage, mold steel, draft, we need to double confirm the injected material before mold design.

Steps in Injection Mold Design

The process of designing an injection mold demands a methodical approach and keen attention to detail. Below is a comprehensive, step-by-step guide accompanied by pertinent tips and best practices for each stage:

1. Product Design Analysis

· Initiate a thorough examination of the product design. Identify critical features, undercuts, and intricate details that may impact the mold design.

· Tip:Establish close collaboration with product designers to ensure a comprehensive grasp of design specifications.

2. Material Selection

· Select a mold material that aligns with criteria such as mold longevity, material compatibility, and production volume.

· Best Practice: Prioritize materials known for their durability and resilience against wear.

3. Gate and Runner Design

· Determine the type and placement of the gate. Consider factors like material flow, part size, and gate residue.

· Tip: Opt for well-structured runners to facilitate proper material distribution.

4. Cavity and Core Design

· Craft the shapes of the cavity and core, paying meticulous attention to parting lines and draft angles.

· Best Practice: Ensure consistent wall thickness to promote even material flow and cooling.

5. Cooling System Planning

· Strategically position cooling channels to maintain uniform mold temperature, thus optimizing cycle times.

· Tip: Integrate baffles or bubblers for efficient heat dissipation.

6. Ejector System Design

· Devise an ejector system to facilitate smooth and seamless part removal.

· Best Practice: Employ a combination of pins, sleeves, and lifters for complex part geometries.

7. Venting Considerations

· Implement sufficient venting to expel air or gases during the molding process.

· Tip: Pay heed to vent placement in areas susceptible to air entrapment.

8. Finalizing Design Details

· Conduct a comprehensive review of the overall mold design, identifying any potential interferences or areas necessitating refinement.

· Best Practice: Undertake a thorough design review with the team to rectify any oversights.

9. Mold Manufacturing

· Collaborate with skilled mold makers or employ advanced manufacturing techniques to actualize the design.

· Tip: Sustain open communication with the manufacturing team for seamless execution.

10. Testing and Iteration

· Conduct rigorous testing to validate the mold's performance. Effect necessary adjustments or refinements if required.

· Best Practice: Execute small-scale production trials to ensure the mold meets prescribed quality standards.

By adhering to these steps and incorporating best practices, you will establish a solid foundation for a successful injection mold design, ultimately enabling efficient and high-quality production.

Common Challenges and Solutions in Injection Mold Design

Designing an injection mold brings forth its own set of challenges. Careful consideration of material selection, meticulous mold configuration, and accommodating intricate part designs are imperative. Yet, these hurdles find resolution through diligent planning, the utilization of advanced simulation tools for precise mold flow analysis, and seeking counsel from seasoned industry experts. Embracing a culture of continuous learning and improvement serves as the cornerstone of triumph in mold design.

The process of meticulously designing an injection mold stands as a linchpin in contemporary manufacturing. Factors such as material selection, precise configurations, and adept handling of complex designs are of paramount importance. Through strategic planning, the utilization of advanced simulation tools, and seeking expert counsel, challenges can be effectively addressed. This process ultimately guarantees the production of superior-quality parts, underscoring its profound significance in the broader scope of the manufacturing industry.

TEAM Rapid Offers Mold Design Supports

We are one of the best injection molding companies in China Our engineering team has many years of experience in mold manufacturing, and whether it is a simple mold or a complex mold, we can provide you with the best solution. Contact TEAM Rapid for the best advice on your next rapid tooling or Rapid Prototype Tooling project.