Selective Laser Sintering (SLS) 3D Printing - What is It and How It Works?

Selective Laser Sintering (SLS) 3D printing is a type of 3D printing method that makes use of the polymer powders to create the parts, components, and prototypes you want by using the additive manufacturing process. The equipment for SLS 3D printing uses laser technology to sinter the polymer powders and make an actual 3D object during the printing process.

The good news about Selective Laser Sintering (SLS) 3D printing is that you can create functional parts using this method, which means you can also use SLS 3D printing to manufacture the final products, not just prototypes.

How Selective Laser Sintering (SLS) 3D Printing Works

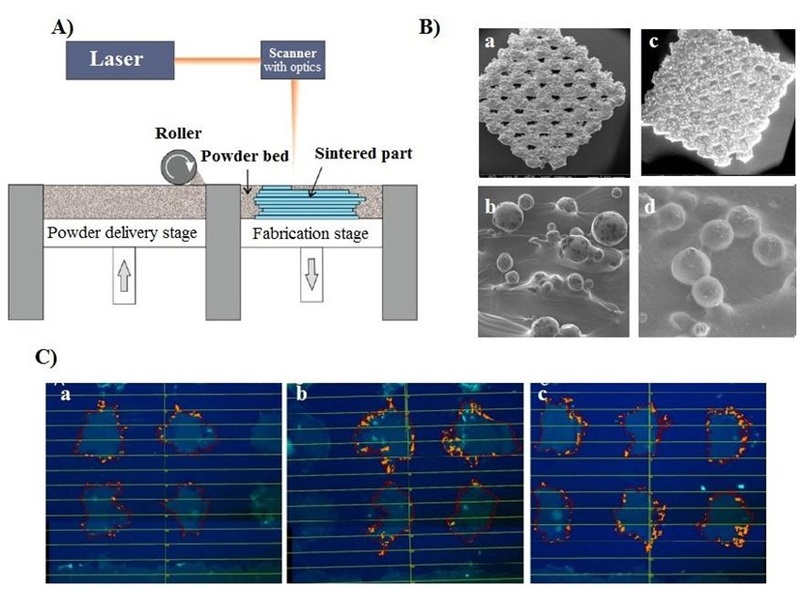

You will need to create your 3D model using the CAD software first, before you can print it into an actual object using SLS. So, it’s important for you to prepare the 3D model design for your rapid prototypes, parts, or custom products before printing them using the SLS 3D printing equipment. After creating the model, you will need to convert it into the file format that is compatible with the SLS printing equipment. Then, you can use the equipment for the printing process. Here’s how Selective Laser Sintering (SLS) 3D printing works:

●Material preparation

The first thing you need to do is to prepare the polymer powder materials. This is the type of thermoplastic material that the SLS printing equipment can use to create the 3D model based on your CAD design. You will need to put the materials inside the build chamber in your SLS printer equipment.

●Heating process includes in selective laser sintering

Next, you will need to turn on the printer and start the heating process. The SLS printing equipment will heat the materials to a temperature below the melting point. This will make it easier for the laser to deliver the material layer by layer later.

●Scanning the 3D model

After the heating process, the SLS 3D printer will scan the 3D model, which you have sent from the CAD software. The 3D model will get through a complete scanning process, and the printer will determine the best way to recreate the 3D model layer by layer until it gets completed.

●Layer-by-layer selective laser sintering printing

Now, the printing process will commence, and the 3D SLS printing equipment will perform a layer-by-layer printing process based on the 3D model you have submitted earlier. The laser will deliver the materials into the printing area. Using additive manufacturing, the laser will build the 3D model from the bottom layer to the top layer, following the 3D model design. This process will take some time to complete, and it can take longer based on the complexity of the design.

●Cooling process

After the printing process is complete, you can’t just take the printed prototype from the printer. You will need to wait for the cooling process to be completed. The cooling process is important to ensure that the printed 3D model has integrity, and it will also ensure that it has dimensional stability. After the cooling process is complete, you can take the printed 3D model out of the printing equipment, so you can use it further.

●Getting the 3D selective laser sintering printed model ready

After taking the printed 3D model out of the printing equipment, you will need to clean it, ensuring that it will not have any debris from the material powders. You will also need to inspect all aspects of the 3D model to ensure that there are no mistakes or errors during the printing process, which might cause deformation or any other problems. At this stage, you can also recycle the remaining powders for the next printing process.

What Makes selective laser sintering(SLS) 3D Printing Better than the Other Methods?

Selective Laser Sintering (SLS) 3D printing can provide you with various advantages when compared to the other 3D printing methods or even other rapid manufacturing methods. With SLS, you will use polymer powders as the primary materials, and these powders will allow you to create functional parts or custom products that you can use in real-world applications. Here are some things that make SLS 3D printing better than the other methods:

●Low-cost production by selective laser sintering

The Selective Laser Sintering (SLS) 3D printing method can offer you more affordable production costs per part or product you create. As the materials are quite affordable to get, you can minimize the costs of production by using this 3D printing method. You can even use SLS 3D printing for producing custom sheet metalwork or products in small quantities with much lower production costs compared to other manufacturing processes.

●Fast production process

Another advantage you can get from the SLS 3D printing method is the fast production process. Selective Laser Sintering (SLS) allows you to produce prototypes, parts, components, or even final products in as fast as 1 day. How fast you can produce your printed 3D models will depend on the complexity of your design and how many items you want to produce. So, this is a great way for you to deliver custom parts or prototypes fast to your clients.

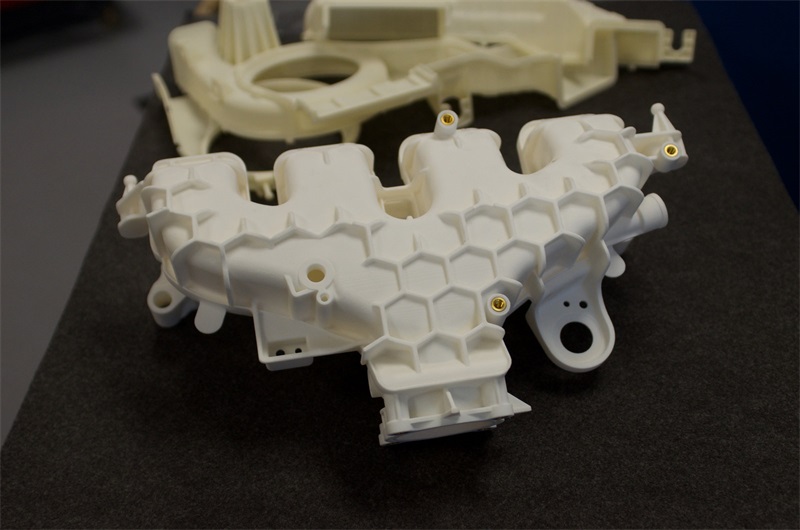

●You can create final products with selective laser sintering

Other 3D printing methods might only allow you to create prototypes for your parts or components. However, you can use the SLS 3D printing method to create final products with it. It means you can create a fully functional product using the Selective Laser Sintering (SLS) printing process, which you can use in your product testing or assembly process.

●Results are on par with injection molding

Selective Laser Sintering is also an excellent alternative to plastic injection molding, as you can get similar results while keeping your production costs within your budget. Moreover, you can also get your products ready much faster when compared to the injection molding process.

●Excellent mechanical properties by selective laser sintering

The 3D printed objects produced from the SLS process also have excellent mechanical properties, meaning that there will be a small chance of deformations when you use this 3D printing process. It gives your items even better durability when you use it in your prototyping or product assembly process.

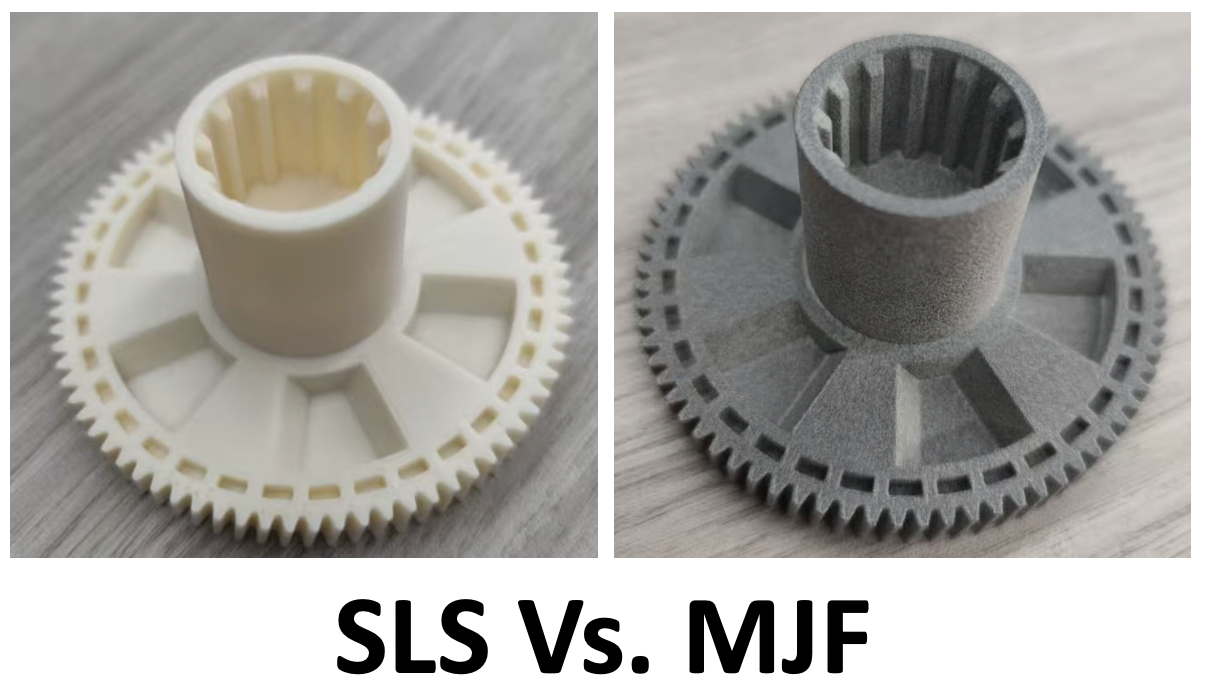

SLS vs. MJF: Which 3D Printing Technology Is Right for You?

Both Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) are advanced powder-bed fusion 3D printing technologies widely used for functional prototypes and low-volume production. They both use nylon-based powders and produce durable, end-use parts—but the way they work, and the results they deliver, differ in important ways.

Category

SLS (Selective Laser Sintering)

MJF (Multi Jet Fusion)

Technology Principle

Uses a high-power laser to sinter powder particles layer by layer

Uses inkjet heads to apply fusing and detailing agents, then fuses powder with infrared energy

Energy Source

Laser

Infrared lamps

Build Speed

Moderate – laser scans each cross-section

Faster – entire layer fused simultaneously

Accuracy & Detail

Very good, slightly lower edge sharpness

Excellent edge definition and fine details

Surface Finish

Slightly rougher texture, typically white or light grey

Smoother and more uniform surface, medium grey

Mechanical Properties

Strong, durable, slightly anisotropic (less strength across layers)

High strength and more isotropic (consistent strength in all directions)

Porosity

Slightly porous

Denser and lower porosity

Dimensional Stability

Excellent

Excellent, often slightly better uniformity

Material Options

Wider range: PA11, PA12, glass-filled nylon, carbon-filled, TPU, etc.

Limited but growing: mainly PA12, PA11, TPU

Color Options

Natural white or easily dyed to any color

Default grey, can be dyed or coated (best in dark colors)

Post-Processing

May require bead blasting or polishing for smooth finish

Minimal finishing needed, smoother as-printed surface

Production Speed

Slower for large builds

Faster build times and cooling cycles

Cost Efficiency

Cost-effective for small-to-medium runs

Better economics for medium-to-large runs

Best for

Functional prototypes, low-volume production, material variety

End-use parts, high-volume production, faster turnaround

Design Freedom

Excellent – no supports, ideal for complex shapes

Excellent – no supports, high consistency

Typical Applications

Prototypes, tooling, custom parts, housings, enclosures

Functional production parts, jigs, fixtures, mechanical components

Surface Color

White/light grey (natural)

Medium grey (natural)

Consistency Between Batches

Very good

Excellent repeatability

Availability

Widely available worldwide

Increasing availability, strong in production environments

Overall Summary

Versatile, proven technology offering wide material choices and strong performance

Fast, consistent, and ideal for production-grade, high-volume 3D printing

Is SLS Right for Your Project?

If you’re working on any of the following, then SLS is definitely worth considering:

1. Small to medium batch production where tooling costs would be prohibitive2. Functional prototypes that need to be tested under real load or real conditions

3. Custom or complex geometries (e.g., parts with internal channels or lightweight lattices)

4. Time‐sensitive projects where speed to market matters

Production scenarios where traditional processes (injection molding, CNC machining) might be delayed or too costly at low volume

Conclusion

With the advantages of Selective Laser Sintering (SLS) and the simple process of this 3D printing method, you can create both simple and complex parts design, rapid prototyping, or even final products with lower and faster production costs. It allows you to produce functional 3D models you can use for product testing, so you can evaluate your product quality with more convenience by using this method. Other than that, it’s also an excellent and more affordable alternative to injection molding and CNC machining.

Besides 3D print services, TEAM Rapid also offer injection molding services, die casting services for your low to high volume manufacturing needs. Contact our team today to request a free quote now!