Injection Molding Threads — Design, Tooling & Best Practices

Reliable threaded features are essential for many plastic parts used in automotive, electronics, consumer goods and industrial assemblies. At TEAM RAPID, we design and produce high-quality injection molded threads parts and threaded-insert parts that deliver dependable fastening, repeatable assembly, and long service life.

What is injection molded threads?

Injection molded threads are internal or external screw threads formed as part of a plastic component during the molding process or created by inserting pre-made metal or plastic threaded inserts after molding. They provide mechanical fastening points for screws, bolts, and mating parts without secondary tapping operations.

Threads Types & Options on Your Injection Molded Parts

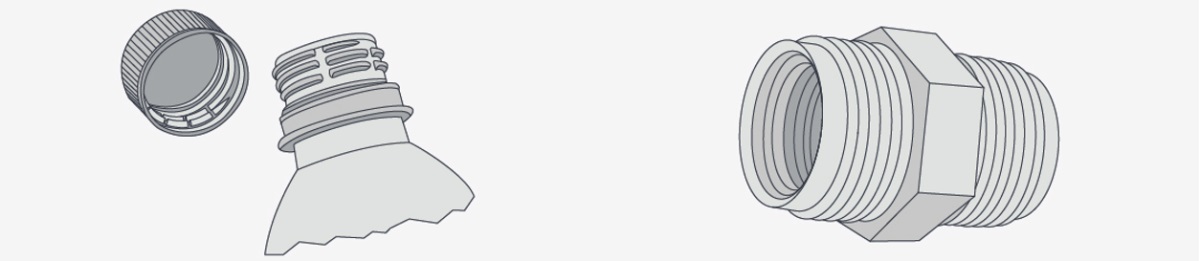

1. Molded (direct) threads are screw threads formed directly into a plastic component during the injection molding process — no secondary tapping or insert installation is required. The threads are produced as the molten resin fills the mold cavity, replicating the thread geometry machined into the core or cavity.

- Injection molding internal threads

- Injection molding external threads

2. Insert threads (helicoil / threaded bushings / knurled inserts)— metal or engineered plastic inserts placed into the mold or installed post-molding for high strength and frequent assembly cycles.

3. Self-tapping screws into molded holes— cost-effective option for light duty; design guidelines must prevent stripping.

4. Overmolded fasteners— combine molded resin over metal fasteners for integrated assemblies.

Design Considerations for Molded Threads

To achieve high-quality molded threads, consider these guidelines:

-

Apply Proper Draft Angles:A small draft (typically 1°–2°) helps in ejection without deforming the thread flanks.

Apply Proper Draft Angles:A small draft (typically 1°–2°) helps in ejection without deforming the thread flanks.

- Maintain Uniform Wall Thickness:Prevents sink marks, voids, and uneven shrinkage.

- Optimize Thread Pitch and Depth:Coarser pitches and rounded thread forms (e.g., modified buttress or Acme profiles) perform better in plastic.

- Select the Right Plastic Material:Engineering resins like Nylon (PA),Polycarbonate (PC),Acetal (POM), and PBT provide good strength and wear resistance for direct threads.

- Ensure Cooling Uniformity:Uneven cooling can cause shrinkage that affects thread accuracy and fit.

- Avoid Sharp Corners:Smooth transitions improve flow and reduce stress concentration near the thread roots.

Common Materials Used in Direct Thread Molding

Direct thread molding allows threads to be formed directly during the injection molding process — without the need for secondary machining or inserts. Choosing the right plastic material is critical to ensure thread strength, durability, and dimensional accuracy. At TEAM RAPID, we use a wide range of engineering-grade thermoplastics for injection molded threaded parts, selected based on application, load, and environmental factors.

| Material | Key Properties | Typical Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Good dimensional stability, easy to mold, and cost-effective. | Consumer products, electronics, and automotive components. |

| Nylon (PA6, PA66, PA12) | Excellent toughness, fatigue resistance, and wear resistance; ideal for self-tapping or load-bearing threads. | Mechanical parts, threaded caps, gears, and housings. |

| Polycarbonate (PC) | High impact strength and rigidity with good heat resistance. | Electrical enclosures, transparent threaded components, and protective housings. |

| Polypropylene (PP) | Lightweight, chemical-resistant, and flexible; ideal for threaded closures and caps. | Packaging, medical components, and consumer products. |

| PBT (Polybutylene Terephthalate) | High stiffness, low friction, and good dimensional stability. | Automotive connectors, threaded plugs, and switches. |

| PEEK (Polyether Ether Ketone) | Exceptional mechanical strength and thermal stability for high-performance applications. | Aerospace, medical, and industrial threaded parts. |

| Acetal (POM, Delrin) | Low friction, high wear resistance, and excellent machinability. | Threaded fasteners, valves, and mechanical linkages. |

| HDPE / LDPE | Good impact resistance and chemical stability. | Bottle caps, fluid fittings, and threaded closures. |

| Glass-Filled Nylon or PBT | Reinforced for added strength, stiffness, and dimensional stability under load. | Heavy-duty threaded housings and automotive parts. |

Why Material Selection Matters

Selecting the proper plastic material for direct thread molding ensures:

Strong and wear-resistant threads that hold up under torque.

Precise dimensions with minimal shrinkage and deformation.

Consistent mold performance, reducing tool wear and maintenance costs.

At TEAM RAPID, our engineers evaluate each project’s functional, mechanical, and environmental requirements to recommend the best resin for threaded plastic parts— helping you achieve superior quality and cost efficiency.

Types of Direct Thread Molding

Direct thread molding is a process where threads are formed directly in the injection molding process without secondary machining. Different types of threads can be molded depending on the application, material, and design requirements.

| Thread Type | Description | Recommended Materials | Typical Applications |

|---|---|---|---|

| Standard Straight Threads | Threads with constant pitch and diameter along the shaft | ABS, Nylon, PC, PBT | General fasteners, caps, plugs, housings |

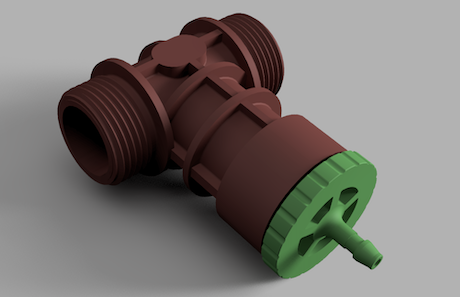

| Tapered Threads | Threads gradually decreasing in diameter to create a tight seal | PP, PE, PBT, Nylon | Fluid/gas-tight closures, pipe fittings, containers |

| Self-Tapping Threads | Threads designed to cut into softer plastics or metal inserts during assembly | Nylon, POM, ABS | Assembly without pre-tapped holes, consumer products |

| Helical Threads | Continuous spiral threads, deeper than standard threads for stronger engagement | Nylon, PC, PBT | Heavy-duty fasteners, threaded enclosures, bottle caps |

| Multi-Start Threads | Threads with multiple starting points for faster engagement | ABS, Nylon, PP | Quick assembly closures, twist-on caps, speed-sensitive applications |

| Fine Threads | Small pitch threads for high-precision applications | PC, Nylon, PBT | Electronics housings, precision mechanical parts |

| Coarse Threads | Larger pitch threads for strength and durability | ABS, Nylon, PBT, Glass-Filled Nylon | Industrial parts, automotive housings, heavy-load applications |

Direct Threads Molding Release Methods

Indirect thread molding, releasing the threaded part from the mold can be challenging due to the intricate helical or tapered thread shapes. Selecting the correct demolding method is essential to prevent damage to the threads, ensure dimensional accuracy, and maintain high-quality finished parts.

Release Method

Description

Applications / Notes

Straight Ejection

The mold opens along the axis of the threaded part, and the part is pushed out using ejector pins or sleeves.

Suitable for straight threads with low to medium depth. Risk of thread damage if part sticks.

Rotary / Unscrewing Ejection

The mold or core rotates to “unscrew” the part from the threaded cavity.

Ideal for helical threads or tapered threads; prevents deformation and preserves thread profile.

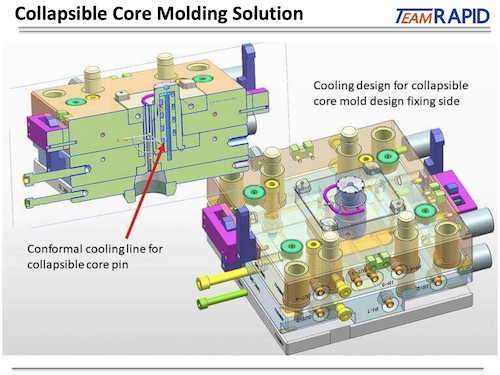

Collapsible Core / Slide Core

Special mold cores collapse or move laterally to release the thread before part ejection.

Used for complex threads or multi-start threads; ensures clean demolding without scratching the threads.

Stripping / Sleeve Ejection

A thin sleeve or collar moves around the threaded part to gently push it out.

Often used for internal threads, fine threads, or fragile materials.

Thread Inserts / Overmolding

Threads are molded over a pre-formed metal or plastic insert. The mold releases the insert first, then the part.

Common for reinforced threads or high-strength applications.

Low-Volume Thread Molding vs. High-Volume Thread Molding

Direct thread molding can be tailored for both low-volume and high-volume production, depending on your project needs. Understanding the differences helps manufacturers optimize cost, efficiency, and part quality.

Low-Volume Thread Molding

Low-Volume Thread Molding

It is ideal for small batches, prototypes, or custom orders. It typically uses simpler molds or single-cavity molds, allowing for quick adjustments and faster setup times. Materials likeNylon, ABS, or PP are commonly used due to their ease of demolding and flexibility. While the cost per part is higher in small batches, low-volume molding is perfect for testing designs, creating limited editions, or producing specialty threaded parts with minimal investment in tooling.

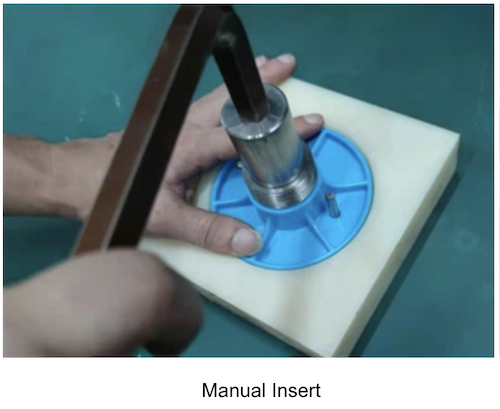

Rapid Tooling: Manual Insert Release Molding Threads

The thread core/cavity is placed into the mold and ejected out together with the molded part, then released molding internal threads are by hand. The method of the manual insert is suitable for low-volume production. To raise production efficiency and achieve rapid manufacturing, we usually make 2 or even more thread cores/cavities for interchanging.

High-Volume Thread Molding

High-Volume Thread Molding

It is designed for large-scale production of thousands or even millions of parts. It uses multi-cavity molds with automated or collapsible cores to maintain high precision and consistency. Engineering-grade materials such as glass-filled Nylon, PBT, and PC are often used to ensure durability, dimensional stability, and long-term performance. While the initial mold cost is higher, the per-unit cost decreases significantly, making it ideal for mass production of consumer goods, automotive components, medical devices, and industrial threaded parts.

Production Tool: Fully Automatic Release Injection Molding Threads

Fully automatic unscrew molding is a unique injection molding process that includes movement and rotation to produce injection molding internal threads parts. First of all, we need to build automatic unscrew molds. These injection molds' unscrewing action is accomplished with a hydraulic or electric motor, making the thread core/cavity precisely have threads ground on them. The cycle time for automatic unscrew molding can be much shorter than manual unscrewing, but the cost of automatic unscrew mold is expensive. Depending on your production amount, such as large volume production, the automatic unscrew molding cuts down the unit part price, even if by several cents per part, the all-in cost can be reduced quite a lot.

How to Choose

Choosing between low-volume and high-volume molding depends on your project goals:

-------- Use low-volume molding for rapid prototyping, custom orders, or small production runs.-------- Use high-volume molding for mass production where efficiency, consistency, and cost-effectiveness are priorities.

At TEAM RAPID, we specialize indirect thread molding for both low-volume and high-volume applications, optimizing mold design, release methods, and material selection to deliver high-quality threaded parts that meet your exact requirements.

TEAM RAPID: Experts in Direct Thread Molding

At TEAM RAPID, we provide high-precision direct thread molding solutions using optimized release methods for every type of thread. Whether you need straight, helical, tapered, or multi-start threads, our engineering team ensures:

At TEAM RAPID, we provide high-precision direct thread molding solutions using optimized release methods for every type of thread. Whether you need straight, helical, tapered, or multi-start threads, our engineering team ensures:

-

Clean demolding without defects

-

Accurate thread dimensions

-

Fast production cycles

-

Durable, high-quality threaded parts

Contact TEAM RAPID today to discuss your direct threads molding project and get a free consultation on the best release method for your parts.

FAQ about Injection Molding Threads

1. What are the different types of threads in thread mold?

1. What are the different types of threads in thread mold?

American Standard 60 sharp thread, tapered pipe thread, and buttress threads are the most frequently specified thread profiles used for plastic molded parts. Among these 3 types, the American Standard or machine screw is the most common. For some special threads, we can consider post-machining threads.

2. Can helicoids be used in plastic molded parts?

Heli-Coils are placed onto the plastic molded parts to enhance the strength and holding power of the screws. They are usually made in hard plastic, steel, or aluminum and installed onto the parts after molding.

3. Can threaded parts be reinforced for heavy-duty applications?

Yes.Threaded plastic parts can be reinforced with glass-filled plastics or metal inserts to increase torque resistance and durability for industrial or mechanical applications.

4. How long does direct thread molding take?

Typical production takes10–15 days after design approval. Rush or prototype orders can be expedited depending on mold complexity and material choice.5. Can I order a small batch of custom threaded parts?

Absolutely. TEAM RAPID supports low-volume thread molding with no strict minimum order quantity (MOQ), making it ideal for prototyping, testing, or limited production runs.6. Can you mold internal threads as well as external threads?

Yes. TEAM RAPID can mold both internal (female) and external (male) threads using manual insert, rotary or collapsible cores to ensure clean demolding and accurate engagement.

7. Can TEAM RAPID produce threads for medical or food-grade applications?

Yes. We can mold threads using FDA-compliant, medical-grade, or food-safe plastics, ensuring regulatory compliance, biocompatibility, and safe use in sensitive applications.