One Of The Best Rapid Prototyping Services Companies in China

At TEAM RAPID, we specialize in producing high-quality rapid prototypes at low cost. With a range of services and technologies, we are the perfect one-stop shop for all your fast prototyping needs. Our sales volume has increased by 20% yearly, starting from 2017. Customers worldwide love our professional rapid prototyping services. We expect to help more customers realize their ideas into rapid prototypes successfully! Are you looking for China rapid prototyping factories? Contact us today to learn more about our prototyping services.

At TEAM RAPID, we specialize in producing high-quality rapid prototypes at low cost. With a range of services and technologies, we are the perfect one-stop shop for all your fast prototyping needs. Our sales volume has increased by 20% yearly, starting from 2017. Customers worldwide love our professional rapid prototyping services. We expect to help more customers realize their ideas into rapid prototypes successfully! Are you looking for China rapid prototyping factories? Contact us today to learn more about our prototyping services.

What is Rapid Prototype? - Rapid Prototyping Definition

A rapid prototype is the design object you can produce using quick prototyping. Rapid prototyping is the manufacturing process that allows you to create hardware components, parts, or objects based on your design requirements. It uses 3D printing or other rapid manufacturing technology to help shape the hardware parts or things based on the design.

The rapid prototyping model you will get might differ from the finished product. The reason is that you will use the prototype as the test objects or product samples for the end product you will mass produce later. 3D prototyping, CNC prototyping, urethane casting, and other prototyping methods will make it easier for you to produce various samples for your product before it gets released as the end product.

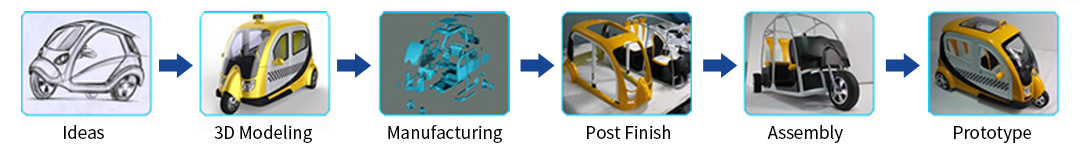

How to Get a Prototype Made

You can create rapid prototypes in a few simple steps:

1. First, you need to create the design for your prototype.

2. Next, use your preferred manufacturing technology to produce the prototype.

3. Review the prototypes you have produced and determine whether they fit your product best.

4. Redesign the prototype if you think they still need some improvements.

5. Then, reproduce the prototype using your preferred manufacturing method.

6. Review the prototypes and start over again until you get the correct version for your product.

Are you looking for China rapid prototyping factories? Besides rapid prototyping services, TEAM RAPID offers low-volume manufacturing services too. We can make your end products in small volumes (such as medical devices rapid prototyping), which means you can have less input but high-quality products to test the market first. Contact us today to learn more now!

Benefits Of Rapid Prototyping and Complete Prototype Services

Rapid prototyping is a manufacturing process that can give plenty of advantages, both for the rapid prototyping companies and the consumers. For instance, manufacturers can speed up their production cycles with the quick prototyping process, to provide faster prototypes for their client's needs. As for the consumers, they can get access to the newer versions of their favorite products faster.

● Easier to Test New Product Features Before Production

● Easier to Test New Product Features Before Production

Rapid prototyping allows you to 3d prototyping your product in fast production cycles so that you can test any new features before production. You can even try a new idea for your product and see if you can work it out.

● Speeding Up the Production Cycles

Prototyping is a manufacturing process that speeds up your production cycles. It will help you go through the testing. Rapid prototyping 3d printing and CNC rapid prototyping are faster, allowing you to mass produce your product as fast as possible.

● Evaluating the Environmental Friendliness of Any Product

The materials you use for your product development might not be healthy for the environment. 3D printing prototype allows you to evaluate the environmental impact of your product before you put it into mass production.

● Reducing the Costs of Production

Prototype machining uses more efficient manufacturing equipment and technology that helps you to produce more parts for your product with less investment costs while keeping the best quality of the end product.

● Allowing Massive Improvements for Each Product by Complete Prototype Services

You can use CNC prototyping to improve various aspects of your product. It will allow you to test multiple parts of your product and improve on them to produce a better version.

● Preventing any Failures in Certain Product Parts by Complete Prototype Services.

You can use a CNC prototype to test various parts of your product and determine whether they have specific weaknesses. Thus, it will be helpful for you to prevent any failures in certain product parts, which can also help you maintain customer satisfaction for your product.

Are you looking for SLS rapid prototyping? Please email us at [email protected] now!

Why Rapid Prototype Service at TEAM RAPID

As one of the best Rapid Prototyping Services Companies in China, TEAM RAPID understands your needs and can provide high-quality prototyping services at a low cost.

- Professional engineering supports starts from prototype making to volume production.

- Multiple processes to make your designs cost-effectively and rapid.

- Experienced technicians work carefully on every detail of prototyping.

- Excellent after-sales service to guarantee rapid prototyping manufacturing timely and satisfactory.

Prototype Companies Commonly Use Rapid Prototyping Processes

Prototyping is the early stage in your product development process, in which you can validate the design, concept, and features of your final product.It allows testing the function to finalize the product specification. It helps to verify against the project requirements and business objectives.Also, prototypes give the customers a hands-on experience of the soon-to-be manufactured product to get their early feedback of the product.

You are replying on various rapid prototype machining and rapid prototype casting technologies to give you the best services for your product. The manufacturing technologies used in the prototype machining will vary from company to company. Fast prototyping companies will use their selection of manufacturing technologies that will work best for them. As one of the best prototype companies, TEAM Rapid, we offer a series of rapid manufacturing methods to make your prototypes:

● 3D Printing

3D printing means creating 3D objects, such as prototypes, hardware parts, or components, layer by layer using the additive manufacturing method. With 3d rapid prototyping, you will need to supply a 3D design to the 3D printing equipment, and the 3D printer will produce the 3d printing prototype according to your supplied design.

● CNC Machining

CNC machining, or CNC rapid prototyping, is the manufacturing process whereby you use pre-programmed software and a particular code control system to control the movements of the manufacturing equipment. Rapid prototyping CNC machining can produce very accurate and precise cutting for the prototypes, which is best for making hardware components that need to fit with other components.

● Vacuum Casting (Urethane Casting)

Vacuum casting / Urethane casting is a manufacturing process that involves pouring molten plastic materials into the molds and then cooling them down to achieve the shape you want to get. You can use this vacuum casting rapid prototyping service to produce complicated parts designs and low-volume manufacturing parts.

● Sheet Metal Fabrication

In sheet metal fabrication, you can use metal sheets to form various prototypes and hardware parts using multiple sheet metal manufacturing methods. It is another kind of prototype machining. You can use different sheet metal materials to create the hardware parts, components, or prototypes. Each sheet metal material has its benefits and disadvantages.

TEAM RAPID always offers our customers the best rapid prototype service to get high-quality parts and prototypes at minimum cost. Contact us to learn more now!

|

|

CNC Prototype |

Polyurethane Castings |

3D Printing Rapid Prototype |

Sheet Metal Prototype |

|

Available Materials: |

Metals & Plastics |

Plastic-like/Rubber-like Materials |

Resins |

Metals & Plastics |

|

Typical Finishes: |

Raw, Painted, Polished, Anodized |

Painted, Polished, Blasted |

Raw, Polished Smooth |

Raw, Painted, Polished, Anodized |

|

Advantages: |

High accuracy &Quick turnaround |

Very cost efficiency at small volume |

Nearly no geometries limitation |

Without investing much on tooling |

|

Disadvantages: |

With cutting limitations |

Post finishes needed |

May not strong enough |

Some post machining needed |

|

Main Factor of Cost: |

Geometry, Material & Volume |

Part size, Finish & Quantity |

Part size & Weight |

Geometry & Part size |

|

Typical Lead Time: |

2-20 Calendar Days |

5-25 Calendar Days |

3-7 Calendar Days |

2-25 Calendar Days |

A Range of Materials and Finishes Available for Our Rapid Prototyping Services

Make your prototypes in specified materials by multiple processes. Customized Finish & Color, more choices to follow your heart!

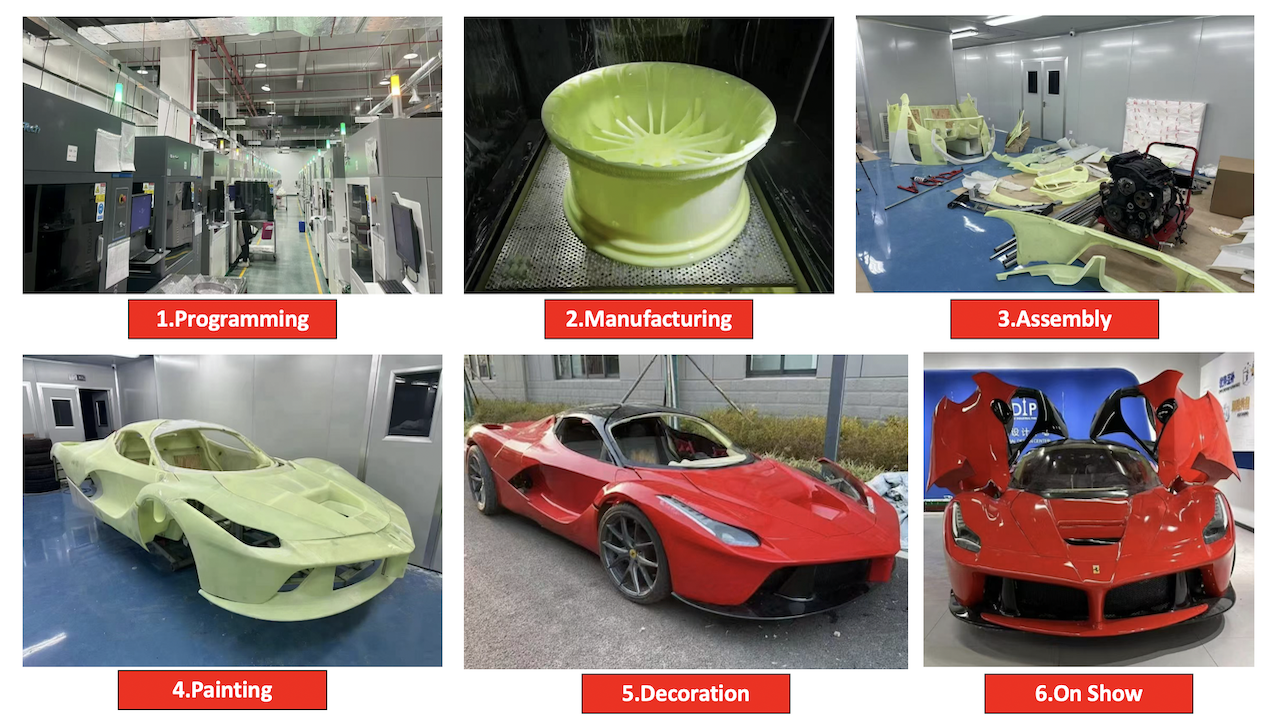

Case Study: Full-Scale Supercar Prototype by TEAM RAPID

A client approached TEAM RAPID to create a full-size supercar prototype for marketing and exhibition. The goal was to turn a digital design into a visually accurate, high-impact show model within a tight schedule.

The Challenge

For a single prototype, traditional methods involving full production tooling are prohibitively slow and expensive. The key challenges were:

- Speed:The prototype needed to be completed in 2 weeks for the show.

- Fidelity:The finished model must accurately reflect complex aerodynamic lines and feature a flawless aesthetic finish, indistinguishable from a production vehicle.

- Complexity:The prototype involves numerous large, intricately designed parts, including the main chassis, body panels, and detailed wheel assemblies.

Project Process

| Step | Process Name | Description of Work |

| 1 | Programming | Engineers prepared and optimized the CAD data, split the body into printable sections, and generated toolpaths for large-format SLA printing and CNC machining. |

| 2 | Manufacturing | All major body panels were produced using industrial SLA machines with high accuracy and a smooth surface quality. |

| 3 | Assembly | Printed parts were trimmed, reinforced, and bonded together. The full-scale vehicle body was assembled with precise alignment. |

| 4 | Painting | The body went through sanding, priming, and high-gloss automotive painting to achieve a smooth, showroom-ready finish. |

| 5 | Decoration | Wheels, lighting elements, trims, and visual details were added to complete the realistic supercar appearance. |

| 6 | On Show | The final prototype was delivered as the highlight of the client’s showroom—eye-catching, dimensionally accurate, and ideal for display and marketing. |

Project Outcomes

- Rapid Production: Full supercar completed in 2weeks, not months

- Cost-Effective: A fraction of the cost compared to traditional clay modeling or low-volume tooling

- High Visual Impact: Automotive-grade finish suitable for showrooms and exhibitions

- Precision Fitment: All panels aligned with excellent accuracy

- Client Satisfaction: Delivered ahead of schedule and exceeded visual expectations

Move From Rapid Prototyping to Volume Production

TEAM RAPID offers a range of solutions to help you move from prototyping to production. CNC Machining, Injection Molding, Pressure Die Casting, and Stamping are the main production processes at TEAM RAPID. No matter for small volume or mass production, we can supply an ideal solution for bringing your new ideas to market on schedule. Talk to us and see how we support your different volumes of production needs.

Frequently Asked Questions

What is Rapid Prototyping?

Rapid prototyping is a manufacturing process that involves creating multiple simulations of a product quickly. It can be used during the development phase to gather feedback and improve the product's design. Through rapid prototyping, a product can be created and tested to improve its features and shape. This strategy is used during the development stage to ensure that the product's overall usability and appearance are optimized.

How Much Does Rapid Prototyping Cost?

Rapid prototyping costs can range from $10 to upwards of $100,000 +. The cost of a prototype depends on several factors. Among these is the type of product that you're seeking to test. Also, whether or not you have the necessary design ready, and the expected materials and timeline. Before you start working on a prototype, it's important that you and your team have a clear understanding of the project's budget. This will allow you to make an informed decision regarding the project.

Is Rapid Prototyping the Same As 3d Printing?

3d printing is one of the rapid prototyping method. Besides from 3d printing, there are other rapid prototyping methods such as CNC machining, vacuum casting, sheet metal prototyping etc.

What is Rapid Prototyping in 3d Printing?

Due to the increasing number of products being created to meet the needs of customers, developers are looking to improve the manufacturing process of their goods. Rapid prototyping technology opens up the possibility of rapid manufacturing. Rapid prototyping in 3d printing involves using a 3D printer to create various parts. It is a type of manufacturing technique that is controlled by computers.

In rapid prototyping, various techniques are used, such as casting and additive manufacturing. In addition to these, there are also other methods that are commonly utilized in the 3D printing process, such as selective laser sintering, powder bed fusion, and stereolithography.

How does Rapid Prototyping Work(How to Do Rapid Prototyping)?

All rapid prototyping techniques undergo these basic steps:

1. Designers and engineers create a CAD Model.

This step involves creating an object using computer-aided design software. Since 3D models are more accurate than traditional wire-frame models, engineers and designers use them more frequently.

2. Output the design in STL, STP, or IGS format.

Due to the consistency of its format, the STL has become a standard for rapid prototyping. The STL format is ideal for rapid prototyping since it doesn't contain any representation of color, texture, or other CAD attributes. 3D printers can read it. The files in IGS or STP are preferred for other procedures, such as casting or CNC machining.

3. For the 3d printing process, the .stl file of the object can be divided into many thin slices and stacked orderly one by one.

The 3rd step is to prepare the STL file for slicing. This process involves creating a database that slices the model into layers. For the other prototyping methods, such as CNC machining, we must have the STP or IGS that can be converted to code and read by the CNC computer.

4. The model is constructed by printing or machining methods.

For 3d printing, after the first layer of the model is completed, a rapid prototyping machine starts working on the second layer. This process is repeated continuously until the model is complete. Most of the machines used in rapid prototyping are autonomous. However, they require human intervention to stop distortion. The rapid prototyping machine works on the second layer until the model is complete. Most of the time, the machines are autonomous, but they require human intervention to stop distortion. For CNC machining, you can see the shape of your design present after cutting.

Moreover, prototypes may require cleaning and surface treatment such as sanding, sealing, or painting to improve appearance and durability.

What is Rapid Prototype?

Rapid prototype is a physical that manufactured base on your design. It is a sample used to proof of concept, visual presentation, functional testing, engineering verification, and low-volume production to test the market.