Rapid Prototyping 2025: Different Types Of Prototyping Methods

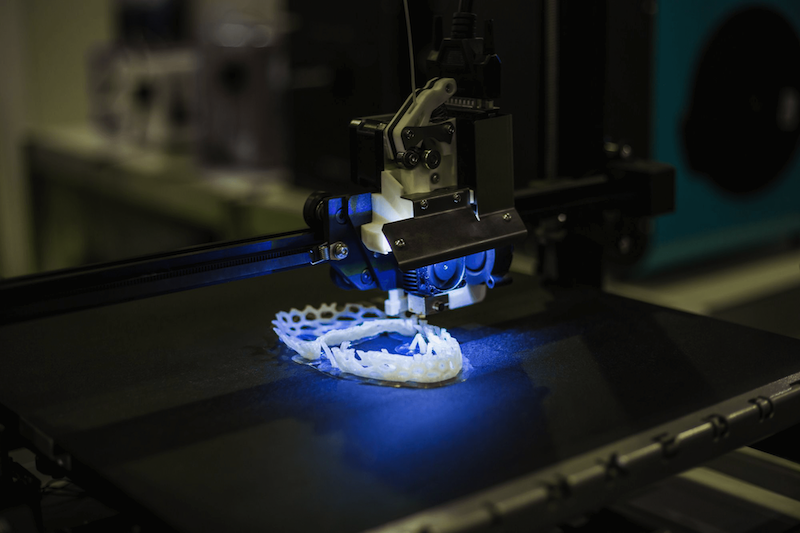

In 2025, prototyping is a fast way to build physical parts, models, and assembly by CAD. Additive manufacturing, also known as 3D printing, is the most common way to perform this rapid manufacturing process. The additive manufacturing technology allows you to produce sample parts rapidly, with a lot of materials options. By rapid prototyping, you can configure your production project based on your preferences.

Using the rapid prototyping process, you can accelerate the entire production operation to produce various prototypes and final parts according to your requirements. It also supports applying small updates to your design and creating different iterations of your prototypes in a matter of minutes or hours. It's the fast-paced production method you will need to fulfill all your project goals and requirements.

What Is Rapid Prototyping - A Flexibility and Versatility Process

Rapid prototyping allows you to create sample parts at a much faster rate, especially when compared to the traditional method. There are also plenty of materials you can choose in all their available characteristics and grades.

Various adjustments can be made for this manufacturing process depending on your project requirements. You can use this process to produce prototypes in any quantity. Also, you can perform this process on a low production budget. For companies that are just starting out and want to have some efficiencies in their production budget and time, rapid prototyping will be an excellent production solution they can have.

Biggest Advantages of Rapid Prototyping

Rapid prototyping offers plenty of advantages for the businesses and clients who want to use this production method in their projects. Aside from producing prototypes, you can also use this production method to produce final parts for your product. So, it is versatile enough to meet all your production expectations. Here are some biggest advantages of prototyping:

● Manufacturing speed and expenses.

Rapid prototyping is a speedy manufacturing process that will shorten the production time you need to spend as much as possible. Meanwhile, the expenses you will need to pay for this fast-paced production method is also cheaper when you compare it with the traditional method. You can also configure various aspects of this production process according to your needs.

● Flexibility of material selection and manufacturing methods.

The selection of materials is quite varied with rapid prototyping. You can choose between plastic and metal materials to create your product samples. You can combine between the two material types, depending on the process you are using. With various types of manufacturing methods available for prototyping, you can choose the one most suitable for your needs and requirements.

● Producing test materials to prevent some production risks.

Rapid prototyping is also useful for you to produce the test materials for your product. These prototype versions of your product will have certain features resembling the final product, which you can test before mass producing it. It can help prevent some production risks, such as damages and defects, before you put them into the commercial production phase.

● Very adjustable and configurable for any production needs.

Rapid manufacturing methods will give you the adjustability and configurability that you need to match your project’s goals. So, you can always pick the options you think are best to use before starting the rapid prototyping process.

● Modern process suitable for modern industrial needs.

Today’s industrial needs are becoming more complex. Thus, you will need more modern methods of manufacturing that can keep up with the latest industrial demands. Rapid prototyping can provide you with the modern process best suited for the current industrial needs. With all the latest equipment and manufacturing technology, you can rely on the prototyping process to give you the best results in your manufacturing production phase.

● Better customer satisfaction for your manufactured products.

Products manufactured with rapid prototyping will usually give you a lot better features, best suited for the customer’s demands. Thus, you can get the best customer satisfaction when you manufacture your products with this method.

Rapid Prototyping Company - What Rapid Prototypes Services Can You Expect?

There are a variety of manufacturing technologies available in prototyping. Layered additive manufacturing is the most used one. Other technologies include high speed machining, die casting, molding, and extruding. Additive manufacturing is the most common rapid prototyping process. Other traditional processes, which can be used to build prototypes, include subtractive and additive manufacturing. Subtractive manufacturing is a process in which a block of material is carved to build the desired parts by milling, grinding or turning. Additive manufacturing is a process that involves solid or liquid material being applied into the desired shape.

Depending on the rapid prototyping company you choose to work with, you can pick from among different types of prototyping processes for your production needs. Each process will offer you different advantages, allowing you to have the flexibility and versatility in your manufacturing production.

Rapid Prototyping by 3D Printing Methods

Rapid prototyping comes in different packages. Each package will give you different features based on your needs. Picking the right rapid prototyping type for your production will be crucial to ensure the best result out of your manufacturing steps. It’s best for you to consult with the rapid prototyping company you are working with before considering the best option for you to choose for your manufacturing production. Here are the different types of prototyping methods:

1. Stereolithography (SLA)

SLA is fast and affordable method to make rapid prototypes. It is the first successful method of commercial 3D printing. The SLA process uses a bath of photosensitive liquid that is solidified layer-by-layer by a computer controlled UV light. It’s best for you to use the SLA method for creating the prototype parts that you can insert to other assembly parts.

Benefits of SLA:

● Creating smooth surfaces for your prototypes.

● Providing you accurate dimensions and measurements for the prototypes.

● Adding some post-processing for your prototypes is easy to do, such as painting.

● Fast and cheap production process and material costs.

● Resistance towards moisture and heat, making your prototypes great to use for the long-term.

2. Selective Laser Sintering (SLS)

The selective laser sintering process uses a powder bed to create a model on various layers by using a laser to heat and sinter the powdered materials. SLS can be used to build metal and plastic prototypes. SLS parts have better strength properties than the SLA parts. SLA vs SLS? SLS parts will need a secondary finishing treatment, as the surface of the finished product is rough. You can use this process if you prefer to build stronger or more durable prototypes or parts for your project.

Benefits of SLS:

● Providing you with better mechanical properties for the rapid prototypes.

● Removing unnecessary production processes to speed up your manufacturing time.

● Requires the use of fewer plastic materials to create the prototypes.

● Best results when you use the post-processing effects, such as coloring and dyeing.

● No need to use any support structures to build your prototypes.

● Empty spaces can be filled with powders, which will be sintered using a laser to build the prototypes or final products you want.

3. FDM or Material Jetting

FDM or material jetting is a cheap and easy-to-use process. FDM uses thermoplastic filament that is melted inside a printing nozzle barrel before the liquid plastic is laid down layer by layer. This process is fast and inexpensive, so it is an ideal option for product development. Also, material jetting or FDM can be used to create highly detailed parts or prototypes, making it the ideal rapid prototyping method to create small prototypes for your project.

Benefits of FDM or material jetting:

● The accuracy of the material jetting process can help make the efficient use of the materials, producing low waste as a result.

● Producing highly-accurate components for your prototypes is easy with this method.

● It can support the creation of highly-detailed parts up to 14 microns in size.

● You can apply multiple colors for the prototypes with this method and even apply those colors in a single production phase.

● Material jetting can produce smooth surfaces for the hardware parts or prototypes you make with it.

4. Selective Laser Melting (SLM)

SLM is a favored process when it comes to building high strength and complex parts. SLM is frequently used in aerospace, automotive and medical industries. Common SLM materials include titanium, aluminum, stainless steel and cobalt chrome alloys. So, this is the rapid prototyping method of choice if you have metal prototypes that need to be prepared for further production.

Benefits of SLM:

● Creating the metal parts, components, and prototypes with superior strength, toughness, and durability.

● Very accurate to create small part details needed for further assemblies.

● The melting process is quite easy to perform and offers a wide range of metal material selection.

● You can use the autoclave method to sterilize the materials for selective laser melting.

● This process supports the use of complex geometric designs.

5. LOM or Sheet Lamination

Compared to SLM and SLS, LOM is cheaper and easier to perform. It does not need special controlled conditions. LOM builds up from a series of thin laminates. Each layer is delivered and bonded onto the previous layer until the part is done. This 3D printing method can help you create bigger components with ease.

Benefits of LOM or sheet lamination:

● You don’t need to create any support for the prototypes when you produce them with this method.

● It is significantly cheaper and faster to produce parts or prototypes with the sheet lamination technique.

● No significant inventory requirements for the materials you use for the LOM process, as it uses widely-available materials.

● LOM supports the creation of prototypes with complex shapes.

● You can apply various details with utmost accuracy.

● Not much handling process is needed to complete the sheet lamination process, which helps reduce stress for the workers.

6. Digital Light Processing

Like SLA, DLP uses the polymerization of resins. DLP is faster and cheaper than SLA. DLP requires post-build curing and the use of support structures. Digital Light Processing improves the SLA method in various aspects, such as by providing more details for the prototypes that you create. You can also use DLP to improve the surface quality further when compared to the SLA method.

Benefits of Digital Light Processing:

● This method offers a more detailed outcome for the prototypes you create with it.

● It helps create various complex geometrical features for your parts.

● You can create parts or components with hollow parts with the DLP method.

● The various material selection is available for the Digital Light Processing, giving you flexibility and versatility in your production.

● It offers a lower overall price per unit, and the rapid prototyping process with it can go very fast, minimizing your wait time significantly.

● You can also create prototypes with higher surface quality with the DLP method.

7. Binder Jetting

Binder jetting technique allows printing one or many parts at one time. However, parts produced by binder jetting have poorer strength than SLS. This method still offers you the best possible quality for your 3D-printed prototypes.

Benefits of Binder Jetting:

● Binder jetting offers high-resolution and high-quality prints for the 3D prototypes based on your design.

● Producing multiple parts or prototypes will be a breeze with binder jetting, making it a preferable manufacturing solution if you are on a tight deadline.

● There is no tooling required, so you can print the prototypes based on your project requirements, no matter how many units or versions you need.

● It also eliminates most of the waste materials for the production process, making it more eco-friendly and cleaner for the environment.

● This method offers plenty of flexibility and freedom in the designing process.

● It can simplify the whole production steps, so binder jetting can add more efficiency in your rapid prototyping process.

● Binder jetting also supports print-on-demand, meaning that you don’t need to open a large inventory just for producing your prototypes.

8. CNC Prototyping

Ideas become reality through the exciting process of CNC prototyping, which uses machinery that is controlled by a computer.

Benefits of CNC rapid prototyping:

● CNC prototyping creates precise models that match design specifications.

● CNC prototyping speeds up testing and improvement phases.

● CNC machines offer design flexibility with various materials.

● CNC prototyping enables complex designs beyond traditional methods.

● CNC prototyping is cost-effective without extra manpower or tools.

● Innovation thrives with CNC prototyping for quick design revisions.

9. Vacuum Casting

One manufacturing method for producing accurate prototypes or low-volume products is vacuum casting. In order to ensure perfect replication of fine details and equal material distribution, liquid ingredients are poured into a silicone mold under vacuum.

Benefits of vacuum casting:

● Vacuum casting faithfully captures fine details and textures.

● It provides material flexibility by using different polyurethane resins.

● Vacuum casting is an economical method for producing small quantities.

● Short lead times for prototypes and small-batch production.

● Flexibility in design with complicated elements and complex geometry.

● Prior to production, vacuum-cast prototypes are helpful for testing and validation.

Why Choose Rapid Prototyping Over the Conventional Production Method?

With various rapid manufacturing production methods you can use today, prototyping continues to become one of the most recommended manufacturing processes, especially for new companies. It offers you a faster production time, cheaper production expenses, and much better flexibility when it comes to producing your prototypes or sample parts. This production-on-demand method will help any company to produce parts or components only for their specific needs. So, should you choose rapid prototyping over the conventional production method today? The answer is yes. It’s best for you to use prototyping to your advantage.

With conventional production methods, companies will need to wait for months just to get their prototypes ready. So, rapid prototyping can give them a significant time cut for their entire production schedule, allowing them to get their prototypes or product samples ready in as fast as a few days. Then, they can perform the tests for their prototypes as soon as possible and determine whether they need to improve on them. So, it’s very convenient for companies to use this method to help improve their product prototypes before sending them for the actual production.

Moreover, rapid prototyping also offers the flexibility and versatility you need the most for the development of your product. You can configure various aspects of your production and ensure that you will only launch the rapid prototype services that has been streamlined for your project needs.

FAQs: What are some important questions concerning prototyping you can stand to benefit from?

What limitations or difficulties come with prototyping?

Although rapid prototyping enables fast creation of design iterations, it has limitations. The size of parts is restricted by equipment constraints. Material options are narrower than final production methods allow. Speed slows for large or intricate parts. Capturing full functionality or durability of complex assemblies or certain materials can prove difficult. Careful project planning and selection of the right prototyping method help overcome these challenges.

How can prototyping support and integrate with the full product development process?

Engineers and designers can quickly construct physical prototypes for testing, assessment, and change prior to production through rapid prototyping. A crucial step in the creation of new products is this procedure. Compared to traditional production, this agile approach reduces time and costs by enabling effective iterations and revisions. Rapid prototyping aids in the identification of necessary improvements by enabling early design verification, functional testing, and user input. With real product representations, it also encourages teamwork. To put it briefly, quick prototyping fosters collaboration accelerates creativity and produces better-quality goods.

Is rapid prototyping a viable method for functional testing and design validation?

By applying rapid prototyping techniques, engineers may produce physical prototypes that closely resemble the final product in a timely manner. This makes it possible to test and improve performance, functionality, and usability repeatedly under different circumstances. Rapid prototyping reveals design flaws, issues, and potential improvements early on by functionally testing prototypes against requirements. However, rapid prototypes may not fully reflect the final product's performance, particularly when specific materials or manufacturing processes are critical.

Are there any confidentiality or intellectual property concerns that should be considered when using rapid prototyping services?

Concerns about secrecy and intellectual property may surface while employing fast prototyping services. To protect sensitive data and designs, every outsourced prototyping partner must have appropriate confidentiality agreements in place. Working with dependable, trustworthy vendors who respect privacy is essential. It's also crucial to use caution when transferring digital files or confidential information. Some businesses continue to use fast prototyping internally in order to better protect their intellectual property. Nonetheless, a lot of service providers can be helpful allies in maintaining design confidentiality during the prototype process since they have procedures and security measures in place to protect intellectual property.

Can you give instances of effective prototyping product development from the actual world?

In a variety of industries, rapid prototyping has proved crucial in the development of numerous successful products. For instance, Fitbit utilized rapid prototyping to swiftly iterate and evaluate various activity tracker designs and capabilities. This iterative process yielded an exceptionally functional and user-friendly product. Tesla also broadly leveraged prototyping to refine the Model S electric car's design, optimize aerodynamics, and test parts, contributing to the vehicle's general innovation. Furthermore, Nike produced multiple Vaporfly running shoe prototypes and tested them with athletes to enhance the design for improved performance. These examples exhibit how rapid prototyping empowers companies to deliver innovative, user-friendly, and optimized products to market.

In addition to rapid prototyping, do you offer any other services like design optimization or post-processing to further enhance the prototypes?

Rapid prototyping offers more than fast model creation. Design optimization services refine and enhance the prototype's functionality, manufacturability, and cost-effectiveness through structural analysis, material usage optimization, and weight reduction identification. Post-processing services apply finishing techniques like smoothing, texturing, painting, and protective coatings to improve appearance and function. Some providers even offer collaborative design assistance, optimizing prototypes to meet manufacturing or requirement specifications. With these ancillary services and support, rapid prototyping produces high-quality prototypes that meet desired design needs.

Is it possible to create designs with extensive details and geometric complexity using fast prototyping?

Printing in three dimensions and other technologies that create prototypes quickly are especially skilled at making intricate designs and complicated shapes that are hard to achieve using traditional production methods. Unlike subtractive techniques like CNC machining or injection moulding, the process of building up layers to create a prototype is not bound by the same restrictions. It can manufacture items with highly complex internal structures. Consider specific manufacturing processes such as selective laser sintering (SLS) and stereolithography (SLA). These methods have the remarkable capability to produce highly intricate and precise structures. This exceptional skill empowers industries like aerospace, automotive, and medical to conceptualize and fabricate intricate and tailored components that perfectly cater to their individual requirements. Rapid prototyping allows engineers and designers to explore complex and creative concepts by removing past constraints.

Which fast prototyping technique is most appropriate for a certain project, and what criteria should be taken into account?

Take into account a number of aspects while choosing a quick prototyping strategy for your project. First, evaluate the design's complexity and geometry, as some technologies excel with specific shapes and resolutions. Second, consider the material properties needed for end use, since methods vary in compatible materials. Third, account for required turnaround time and budget; methods differ in speed, cost, and scalability. Fourth, determine the accuracy and surface finish needed. Finally, consider any post-processing or finishing requirements. Carefully weighing these factors will identify the method that best fits the project's unique needs.

In what ways can fast prototyping allow for further customization and customization of products?

Customizing and personalizing things, which has historically been expensive and time-consuming with traditional production procedures, is being revolutionized by rapid prototyping. This is because each design modification requires purchasing new molds and tools when using traditional methods. On the other hand, rapid prototyping uses digital design files to facilitate the quick and reasonably priced creation of customized goods as needed. This eliminates the need for unnecessary inventories and bulk production. Consequently, companies can now provide tailor-made solutions to individual customers or meet specific demands in the market. Furthermore, the utilization of rapid prototyping allows for the exploration of diverse design alternatives and choices, granting consumers the opportunity to actively engage in the development of a product. The capacity to swiftly iterate and improve designs based on user input not only amplifies the degree of customization but also enhances the capabilities for personalization.

Does rapid prototyping offer any environmental sustainability benefits?

Rapid prototyping reduces energy use, overproduction, and material waste, among other beneficial environmental consequences. Unlike subtractive manufacturing methods, which remove material, rapid prototyping is an additive process that uses only the amount of material required to create a prototype. This method reduces waste. Furthermore, lighter, more efficient designs are made possible by quick prototyping, which lowers energy usage throughout the course of a product's lifetime. It also reduces the need for physical prototypes and rework by rapidly iterating designs, thus lowering waste. Furthermore, quick prototyping contributes to a decrease in wasteful consumption and overproduction by enabling customized items. In conclusion, quick prototyping encourages a more environmentally friendly, sustainable approach to product

What disadvantages or hazards can arise if the exclusive approach to product development is rapid prototyping?

Prototyping has benefits, but it's important to be aware of any potential dangers and disadvantages as well. One significant risk involves the possibility of overlooking design limitations or challenges that may arise during stages of product development or production. Rapid prototyping might not fully encompass material properties, complexities of assembly or critical manufacturing considerations necessary, for the success of the product. Over reliance on prototyping without taking these factors into account can lead to issues or delays when scaling up production. Furthermore the costs associated with prototyping can be relatively high in comparison to manufacturing methods particularly when dealing with large or intricate prototypes. When venturing into product development it is essential to assess both the costs and benefits of transitioning from rapid prototyping to mass production. It is important to consider how scaling up production may impact expenses and feasibility. Striking a balance between the speed and flexibility offered by prototyping while mitigating risks associated with mass production is paramount, in ensuring an efficient development process.

How does rapidly creating prototypes help designers improve their iterations and refine their work through feedback?

Rapid prototyping greatly enhances design iteration and refinement through the quick fabrication of physical prototypes that allow designers and engineers to assess and improve form, fit, and function early in development. By providing tangible manifestations of ideas that facilitate collaboration and incorporate stakeholder feedback into subsequent versions, rapid prototyping enables faster, iterative optimization resulting in innovative, high-quality products.

Are fast prototyping techniques primarily restricted to the creation of prototypes, or can they also be utilized to build functional end-use parts?

Rapid prototyping is mainly used for prototype, though it can also produce functional final items in some circumstances. Its appropriateness is determined by the material, design intricacy, and requirements for durability. While large-scale production is the strong suit of traditional manufacturing, small batches or custom items are better served by rapid prototyping. Stronger, more functional parts may be produced through fast prototyping, thanks to ongoing advancements in materials and technologies. However, whether rapid prototyping can achieve end-use part requirements over alternative approaches depends on a number of criteria, including cost, speed, and material qualities.

Which safety measures need to be followed while utilizing materials and technologies for fast prototyping?

Following safety guidelines is essential when using materials and technologies for rapid prototyping. The operations could entail chemicals, lasers, or high temperatures, so it's imperative to wear safety gear and follow instructions. Make sure there is enough ventilation if materials or processes emit fumes or particulates. Consult the manufacturer's safety instructions before handling or disposing of any products that might be dangerous. It is advised to have adequate instruction on the tools and materials to guarantee safe operation. Furthermore, dangers are reduced by routine equipment maintenance and inspection.

Can hybrid or multi-material prototypes be produced using rapid prototyping techniques?

Advances in rapid prototyping technology now allow designers to build hybrid or multi-material prototypes in a single run. Technologies such as polyjet printing, selective laser sintering, and multi-jet fusion allow designers to combine several materials with varying properties into a single prototype. When replicating items that require different materials for different functions, this option is extremely helpful. For example, in order to effectively depict the final product, a prototype might require numerous colors or both stiff and flexible materials. Before going into mass production, designers and engineers may more accurately assess performance, functionality, and aesthetics thanks to multi-material prototyping.

What potential future developments or trends might we expect to see in fast prototyping?

Technology for rapid prototyping is constantly developing and expanding in a number of important domains. First, 3D printing speeds and efficiency will likely improve to enable faster prototype development. Additionally, new materials with expanded functional properties like enhanced strength, heat resistance, and conductivity will broaden applications. Rapid prototyping may also increasingly integrate with other cutting-edge technologies including AI and VR to refine designs through advanced simulations and iterations. Moreover, additive manufacturing adoption in automotive, aerospace, and other sectors beyond prototyping itself will drive large-scale production innovations. Finally, greater collaboration between designers, engineers, and materials scientists could further optimize processes and materials tailored specifically for rapid prototyping. Overall, major progress in 3D printing capabilities, advanced materials, cross-disciplinary integration, industry adoption, and design optimization will shape the future of this rapidly accelerating field.

Is it possible to use fast prototyping to create interactive or functional prototypes using sensors and electronics?

3D print service and other rapid prototyping technologies allow designers to create interactive, functional prototypes with embedded electronics. By incorporating spaces and channels into the design, sensors, circuit boards, and other electronic components can be integrated directly into the prototype. This replication of the end product's functionality and user experience benefits designers in fields like consumer electronics, medical devices, and Internet of Things applications. However, when integrating electronics into fast-moving prototypes, designers must consider compatibility of materials, wiring, assembly, and testing.

Can food dishes or other culinary ideas be prototyped using rapid prototyping techniques?

Food prototypes can be produced quickly through the use of 3D food printing and other food-grade materials and technology. Layers of edible materials, such chocolate, sugar, or food pastes, are used to create complex structures and designs in cooking. This allows chefs, designers, and enthusiasts to explore innovative forms, textures, and presentations. Moreover, rapid prototyping can customize designs for individual preferences and dietary needs. However, while excellent for visualizing and structuring, these prototypes may not fully replicate the final dish's taste and cooking qualities. The focus rests on conceptualizing culinary designs, not consumption.

In what ways may wearable technology and fashion benefit from prototyping?

Rapid prototyping technologies, such as 3D printing, have enabled major advances in wearable technology and fashion. 3D printing allows designers to swiftly prototype elaborate, personalized jewelry, clothing, and accessories, experimenting with unusual structures, textures, and shapes not possible with conventional manufacturing methods. Additionally, rapid iterations and customization enabled by these technologies let designers refine designs rapidly based on user feedback and body measurements. In wearable technology, rapid prototyping facilitates creating integrated device and sensor prototypes for smart textiles, interactive garments, and health monitoring systems. Overall, combining rapid prototyping with fashion and wearables opens up new creative possibilities for personalization and functionality in these industries.

Conclusion

Rapid prototyping is a cost-effective way to create sample 3d printing parts or prototypes for your production project. It is an automated process which requires less labor to operate. This process is also precise and helps to reduce the material wastage and does not require special tools. Efficiency, speed, and affordability are the aspects that can be offered by this production process.

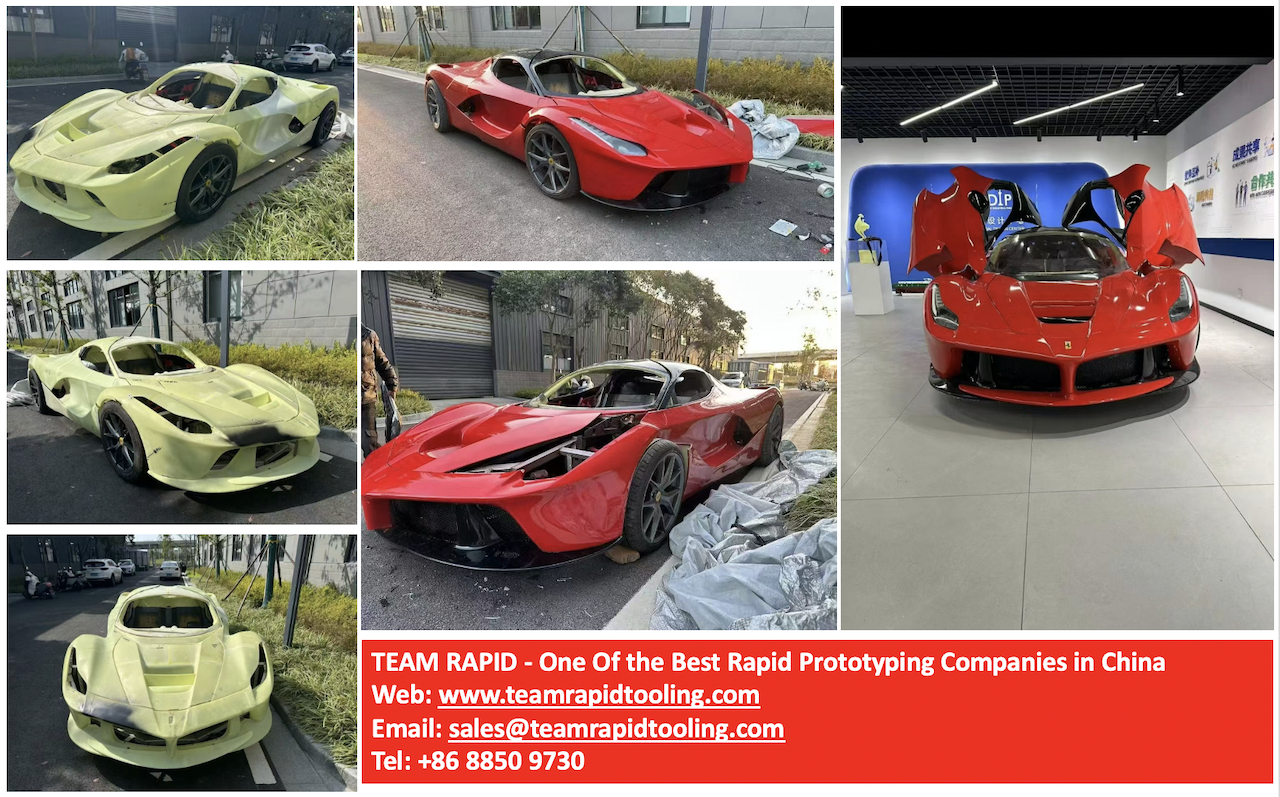

Contact Us & Get Started with Rapid Prototyping

Ready to bring your ideas to life with high-quality rapid prototyping? At TEAM RAPID, we help engineers, designers, and manufacturers transform concepts into precise, functional prototypes using the latest technologies. Whether you need 3D printing, CNC machining, SLA, SLS, or aluminum/ABS prototypes, our experienced team provides guidance from material selection to production-ready prototypes, ensuring your project meets exact specifications.

As one of the largest rapid prototyping companies, TEAM Rapid offers high quality rapid prototyping services to worldwide customers. If you need help on your prototyping projects, contact us at [email protected] today. We can help you configure your prototyping projects based on your requirements.