Difference between Direct and Indirect Rapid Tooling Process -2026

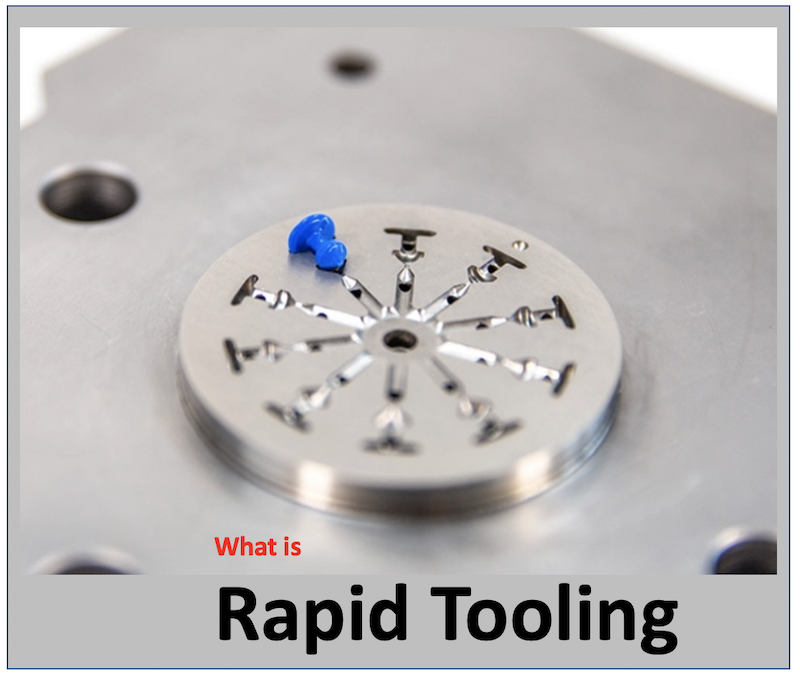

Have you ever noticed that the fabrication industry has evolved a lot in the last decade? Do you find the reason behind this immense transformation? If not, then remember that it is all because of rapid tooling. This rapid manufacturing technology has increased the applications in a short time and therefore the industry has seen such a huge rise in 2024.Rapid Tooling is actually defined as the process involving the rapid prototyping techniques combined along with the traditional tools to offer molds at a faster rate. It also accesses the rapid prototyping processes directly to fabricate the tool. Because of the increasing demand for cheaper yet faster tools, a countless number of RT methods has been introduced and access throughout the world.

Benefits of rapid tooling:

- Tooling time and cost is lower when compared to the conventional tool

- The product brings into the current market previous than the planned time

- This tool is utilized for small quantity requirements including the rapid prototyping

- The rapid tooling facilitates different kinds of products manufactured in the large range of materials

- It helps to resolve the existing problems and used to develop molds for several commercial operations

- This tool is an effective method to produce quality products to customers and allows the organization to produce products with huge benefits

Types Of Rapid Tooling

Rapid Tooling is divided into two different types based on the manufacturing methods such as indirect rapid tooling and direct rapid tooling.In direct rapid tooling, RT methods have been used for the straight production of molds and do not require any kind of specific pattern. The most techniques used in this type are LENS, direct AIM, DMLS, laminated tooling, a quick cast method, and much more.

Currently, indirect tooling method is the most common type of RI method. It is actually used for the purpose of prototyping, not for direct production methods. It is further classified into soft tooling and hard tooling according to the materials used. Spray metal tooling, 3D keltool, and silicone rubber tooling are the techniques used in this tooling.

Direct vs. Indirect Rapid Tooling Comparison Table

| Category | Direct Rapid Tooling | Indirect Rapid Tooling |

|---|---|---|

| Definition | Tooling is manufactured directly from CAD data without any intermediate pattern | Tooling is created using a master pattern produced by rapid prototyping |

| Tooling workflow | CAD model → Tool fabrication → Production | CAD model → Master pattern → Tool fabrication → Production |

| Intermediate pattern | Not required | Required |

| Typical manufacturing methods | Metal 3D printing, CNC machining, hybrid additive-subtractive processes | SLA, SLS, FDM, CNC for patterns; silicone molding, epoxy tooling, casting |

| Tool material | Metal alloys, hardened steel, aluminum | Silicone rubber, epoxy resin, soft metals |

| Lead time | Very short | Short, but longer than direct tooling |

| Initial tooling cost | Higher | Lower |

| Tooling accuracy | High and consistent | Moderate to high (depends on pattern quality) |

| Surface finish | Good to excellent | Good, may require post-processing |

| Tool strength & durability | High | Lower than direct tooling |

| Typical production volume | Low to medium volume | Prototype to low volume |

| Suitable molding processes | Injection molding, die casting, compression molding | Vacuum casting, silicone molding, prototype molding |

| Design iteration speed | Fast (digital updates only) | Slower (new master pattern required) |

| Part performance | Close to production-grade | Suitable for functional and visual prototypes |

| Best use cases | Bridge tooling, functional testing, short-run production | Concept validation, cost-sensitive prototypes, frequent design changes |

Contact TEAM RAPID for Direct & Indirect Rapid Tooling Solutions

Project cost, lead time, and part performance can be differed quite a lot when choose the difference rapid tooling method. TEAM RAPID can give you the suggestion and solution for no matter you need direct rapid tooling for functional, production-like parts or indirect rapid tooling for cost-effective prototypes and fast iterations.

Our engineering team works closely with you to:

- Evaluate your design, material, and volume requirements

- Recommend the most suitable direct or indirect rapid tooling approach

- Optimize tooling design for speed, accuracy, and cost efficiency

- Deliver high-quality parts for prototyping, testing, and low-volume production

Get a Fast Quote & Engineering Support

Have a CAD file, drawing, or just an idea? Contact TEAM RAPID today to receive professional feedback, quick quotations, and practical manufacturing advice.

- Email: [email protected]

- Online Inquiry:Submit your RFQ through our website

- Response Time:Typically within 24 hours on business days

Send us your drawings now and let TEAM RAPID help you turn your design into reliable parts—faster and smarter.

Frequently Asked Questions – Direct vs. Indirect Rapid Tooling

1. Is direct rapid tooling always the best choice when speed is critical?

Not always, it depends on how many design changes and tool copies your project needs. Indirect rapid tooling can be faster overall if multiple tools or iterations are required from the same master pattern.

2. How does tooling lifespan differ between direct and indirect rapid tooling?

- Direct rapid tooling generally provides a longer tool life due to stronger tooling materials such as aluminum or steel.

- Indirect rapid tooling tools—often made from silicone or epoxy—have a shorter lifespan and are better suited for limited production cycles.

3. Can indirect rapid tooling handle complex geometries?

Yes. Indirect rapid tooling is well-suited for complex geometries, undercuts, and fine details, especially when silicone molds or flexible tooling materials are used. This makes it ideal for visually accurate and complex prototype parts.