Metals Die Casting: Complete Basics and Design Tips to Get Start

Before knowing about the metals die cast, it’s best for you to know about die casting first. Die casting is the process that molten metal is poured into a steel mold by high pressure and cooling the molten metal solidifies to form a solid casting.

What is Die Casting?

Die casting is a common production process that allows you to manufacture various hardware components made of various metal alloys for further product assembly process. This process allows you to produce various metal die casting products with high precision, which is necessary for the assembly of various products, such as consumer electronics, automobile parts, manufacturing equipment, and so on.

Meanwhile, die cast metal means the metal used for the die casting process.There are many materials can be used in die casting like tin, lead, zinc, aluminum, magnesium to copper alloys and even iron alloys and stainless steel. These metals must be non-ferrous, and they will need to get melted first before you put them into the molds for the die casting process.

How Die Casting Operates?

Die casting involves the injection of molten metals with lower melting points, like zinc and aluminum, into a specialized mould, followed by cooling. This method operates through two distinct mechanisms, hot and cold chamber casting, catering to the production of both simple and intricate sheet metal parts based on the material's melting point.

This process stands out for its distinctive approach, serving as a pivotal technique in manufacturing numerous metal components vital for both consumer and industrial products. Yet, before delving into utilizing this process or engaging companies offering such services, it's crucial to attain a comprehensive understanding of its workings. Consequently, this article aims to provide insights into die casting, unravel its historical context, elucidate its mechanisms, and weigh its advantages and disadvantages.

Understanding Die Casting

Die casting stands as a process entailing the melting of metals with low melting points, subsequently injecting them into a pre-existing mold referred to as the die-casting mold. These molds, fashioned from steel through manufacturing methods like CNC machining, are uniquely tailored for individual projects. Consequently, sheet metal parts produced via die casting boast remarkable accuracy, precision, and repeatability.

Historical Evolution of Die Casting in Manufacturing

The roots of die casting extend as far back as 1800, marking its significance within the printing industry. In 1849, Sturges engineered a manually operated die-casting machine for printing purposes, elevating its precision, creativity, and versatility in shaping intricate forms. Subsequently, in 1855, Otto Mergenthaler introduced the linotype machine, renowned for its enhanced efficiency, revolutionizing the publishing sector.

The 19th century witnessed a surge in demand for die-casting machines across various industries, driven by their inherent advantages. This era also witnessed technological advancements; aluminum superseded tin and lead due to its superior quality. Furthermore, the original low-pressure injection die-casting process evolved into high-pressure casting methods, marking a significant shift.

Citing Grand View Research, the Die Casting Industry held a substantial 49.7% share of the global market in 2016, attributed to its cost-effectiveness and consistent production rates.

Varieties of Die Casting Processes

Diverse die-casting methods share a common objective: crafting molds through injected molten metal. Depending on the melted metal type, part geometry, and size, these methods offer superior results compared to alternative techniques. The principal die-casting processes are hot-chamber and cold-chamber die-casting.

· Hot-Chamber Die Casting Process (Hot Casting)

Referred to as gooseneck casting or hot casting, this method prevails as the more prevalent die-casting process. Here, the cylinder chamber of the injection mechanism submerges entirely in the molten metal bath. A gooseneck metal feed system draws molten metal into the die cavity, resulting in faster part production rates than the cold-chamber process.

Although direct immersion expedites mold injection, it heightens susceptibility to corrosion. Consequently, this method best suits applications utilizing metals boasting low melting points and high fluidity, such as lead, magnesium, zinc, and copper.

· Cold-Chamber Die Casting Process

Closely resembling hot-chamber die casting this process prioritizes mitigating machine corrosion over production efficiency. Melted metal is ladled either automatically or manually into the injection system, eliminating the need for the injection mechanism's immersion in the molten metal bath.

For applications unsuitable for the immersion-based design of hot-chamber die casting, the cold-chamber process emerges as an excellent alternative, especially for casting metals with high melting temperatures like aluminum and its alloys.

Additional Die Casting Variants

Beyond the primary die-casting methods, several variations exist:

· Low-pressure die casting

Ideal for symmetrically shaped aluminum components like vehicle wheels, involves a vertical mold above the molten metal bath connected via a riser tube. Pressurizing the chamber (usually between 20 and 100kPa) pulls metal upward into the mold, yielding high casting yields sans feeders.

· Vacuum die casting

Akin to low-pressure die casting but with reversed locations of the mold and molten metal bath, vacuum die casting uses a vacuum in the chamber to force molten metal into the mold cavity. It minimizes turbulence and gas inclusions, proving beneficial for applications requiring post-casting heat treatment.

· Squeeze casting

It targets metals and alloys with low fluidity, delivering highly dense products, often associated with molten aluminum for fiber reinforcement applications.

· Semi-solid die casting or Thixo forming

It results in minimal porosity and maximum density by transitioning metal between solid and liquid phases, yielding improved precision. Non-ferrous metals like magnesium and aluminum alloys are commonly utilized in this process.

What is die cast metal?Stainless Steel Casting?Types of Die Casting Metals You Can Use In Die Casting Process.

There are various types of metals you can use for die casting. The one important characteristic of metal die cast is that it must be non-ferrous, meaning that it must not contain any iron materials within the metal alloys. This is important because you don’t want the end product to get exposed to corrosion later. Here are the die cast metals you can use for metal die casting:

● Aluminum - The Most Popular Metal Used in Die Casting Manufacturing.

Aluminum is the preferable metal alloy used for die casting various automotive-related products. Die casting aluminum is lightweight, and it has various beneficial properties, such as corrosion-free, excellent strength-to-weight ratio, and resistance to high temperatures.

● Magnesium - The Light Die Casting Metal with Excellent Properties.

Magnesium is the metal alloy that has excellent heat and electrical conductivity, and this is a very light and durable metal alloy you can use in your die casting process. It is also the metal alloy you can recycle with ease.

● Brass - It is Good to Have Conductivity Brass Parts by Casting Process.

Brass is the mix of copper and zinc. It has an excellent electrical conductivity with spark resistance. You can also apply various finishing options when die casting brass, such as applying the mechanical finishing and chrome plating.

● Zinc - The Metal Casting Parts Used Widely in Security Lock

A lot of die cast zinc metal alloys are used in various electronic components products, such as telecommunications and computing products. It has a smooth surface finish, and it is corrosion resistant with a good impact strength. Zinc metal alloy is also very easy to pressure die casting.

● Cast Stainless Steel - by Investment Casting.

Stainless Steel Casting, also called stainless steel investment casting. It needs to build an original wax model and the image with plaster and successive layers until a strong shell surrounds the model. When the wax is melted, the molten stainless steel is poured into the mold to create a replica of the original wax pattern. Cast stainless steel is economical. It offers high resolution, sophisticated detail and smooth surface finish Die casting steel offers numerous of benefits. Casting size is usually ranging from .1 to 14 inches. Weight is ranging from a few grams to 50 pounds up. Stainless steel pressure die casting parts have a very smooth finish. It offers tight tolerances ±.01’’ per inch. The whole process is reliable and repeatable. It allows design and casting versatility. Overall, stainless steel casting is an efficient and affordable production process. There are many types of stainless steel can be used is die casting. SS304 has cleanliness standard and good corrosion resistance property, it is commonly used in medical, plumbing, watering. SS316 is an ideal option for automotive, food and diary use industry because of its superior corrosion resistant property. 304L and 316L are softer and 410 and 416 are high strength and very machinable. 7-4 Very strong which can be used in military.

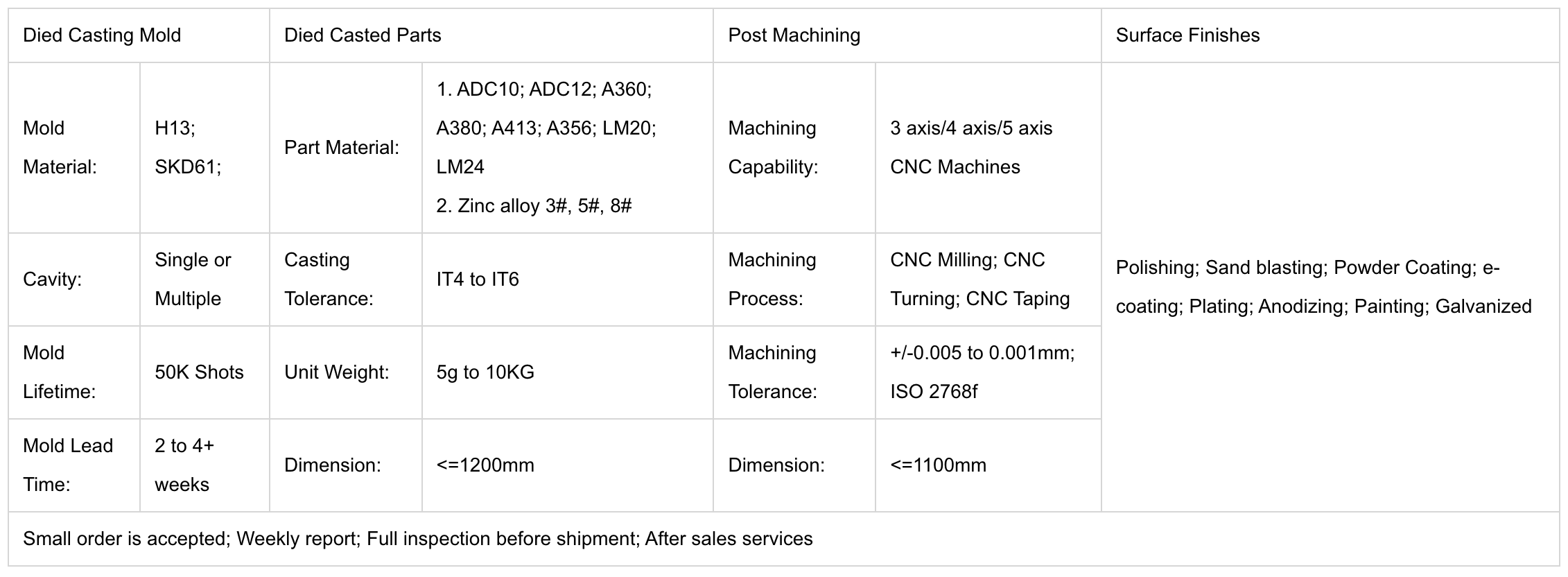

Die Casting Manufacturing At TEAM Rapid

At TEAM Rapid, as a professional China tooling and metal molder die casting factory, we have more than 10 years in die casting and stainless steel casting. Our strong capability allows us to produce casting stainless steel and die cast metal parts for a wide range of industries like automotive, machinery, medical, daily commodity, aerospace, electrical and so on. We work with customers ensure that we offer high-quality metals die cast parts which meet their specifications exactly and at reasonable pricing. Want to know more or have a die casting enquiry? Contact us or send us an email at [email protected] today.

Surface Finish Options for Die Casting Parts

Achieving optimal surface finishes proves crucial for die-casted surfaces, augmenting their visual appeal and durability. Surface finishing processes offer several benefits:

·Enhanced Aesthetics

Surface finishing rectifies manufacturing faults, lending a clean and visually appealing appearance. Some finishing materials introduce beautiful designs and colors, further enhancing aesthetic value.

·Defect Elimination

Various finishing methods, including rounding sharp edges and removing excess residues, effectively eliminate surface imperfections incurred during manufacturing, often utilizing abrasives for fault removal.

·Facilitating Coating Adhesion

Smoothening surfaces through finishing enhances their capacity to absorb paints and coatings, resulting in more robust layers and improved adhesion.

·Increased Corrosion Resistance

The application of non-corrosive coats during finishing mitigates corrosion risks, enhancing the durability of metals prone to reactivity with moisture. Stainless steel surfaces, for instance, exhibit high corrosion resistance.

·Chemical Resistance and Conductivity Improvement

Tough coatings applied during surface finishing fortify surfaces against chemicals and improve electrical conductivity, impacting properties like solderability and contact resistance, crucial for specific applications. Selecting appropriate surface finishes ensures suitable conductivity values for specific applications requiring enhanced conductivity.

Different Types of Surface Finishes Available for Casting Parts

A myriad of surface finishes cater to diverse needs. Here are some popularly utilized options:

1. E-Coat

Known as paint deposition, E-coat employs electricity to attract paint products to metal surfaces. While primarily used for functional purposes like protection, it can serve as an undercoat for other coatings like powder coats. Clear-clad E-coats are employed across various consumer goods, including jewelry, hardware, giftware, and eyeglass frames.

2. Black Oxide

Produced through a chemical reaction by dipping parts into a heated salt solution, black oxide acts as a conversion coating. It provides corrosion resistance, absorbs oil and wax, and offers resilience against peeling and chipping. This finish is chosen for surgical instruments, gears, fasteners, and hardware requiring corrosion resistance, as well as components in military, architectural, and furniture assemblies.

3. Powder Coating

This dry coating method, prevalent in industrial equipment finishing, boasts toughness and resistance to dings and scratches. Available in different gloss levels, textures, and colours, it adheres to various surfaces like plastic, steel, and concrete. Widely used in the automotive industry for components like hubcaps, shock absorbers, vehicle frames, and public transport items.

4. Anodizing

Cost-friendly and corrosion-resistant, anodizing seals parts in various colors like red, blue, and black. It's a durable, non-conductive protective coating and an environmentally friendly process due to minimal hazardous waste production. Particularly applied in the aviation industry for aluminum treatment in aircraft parts and frame anodizing aluminum components.

5. Chromate

Classified as a conversion finish, chromate offers corrosion resistance in various forms like chrome plating and chromate with and without zinc. This cost-effective coating is found on hardware, power tools, and components requiring corrosion protection.

Each of these surface finishes caters to specific needs, ensuring protection, aesthetic appeal, and functionality across a wide array of industries and applications.

Advantages of Metals Die Cast in Industries

The high pressure die casting method has been around as far back as the 18th century, when the first die casting method was getting patented. Throughout the centuries, the die casting method has been through massive improvements until today. Nowadays, we can use much more efficient die casting methods using various metal alloys such as cast stainless steel. Here are the advantages of die cast metal:

● Creating simple and complex metal shape designs.

You can use the metal die casting process to create various simple and complex metal items or objects for your production needs. Die casting can be useful for creating hardware components, from the smaller components you can use for small electronic devices to bigger components you can use in the automotive and aerospace industries.

● Producing various hardware components at high production rates.

Die casting can also provide you with a high volume of production process, so it’s great for producing large volumes of hardware components in the fastest possible time. There will also be little, or no machining required for you to produce the components you want with die casting.

● Various metal alloy options for your product assemblies.

There are various die-casting metal alloys you can use for die casting such as casting stainless steel, depending on your needs. For instance, you can use zinc metal alloys to produce hardware components for various consumer electronic products, since it has an excellent electrical conductivity.

● Metal plating is possible for certain die cast metals.

With the die casting process, you can also apply the metal plating process afterwards. This is possible for certain metal alloys, such as brass. You can also pick various metal plating options based on your needs.

Applications of Die Casting Parts

Die casting finds its niche in production and rapid manufacturing medium-sized parts that exhibit intricate details. This technique predominantly applies to nonferrous metals like magnesium and aluminum. As one of the largest casting methods, die casting finds its utility across diverse sectors, contributing to the production of consumer, commercial, and industrial products. These range from automobiles to toys and encompass parts of bahroom sink faucets, connector housings, gears, and more. The die-casting process stands out for its ability to craft distinctive and highly functional parts and components. Some notable applications of this process include:

·Consumer and Industrial Product Manufacturing

Sink faucets, compressor pistons, connector rods, heat sinks, etc., are among the wide array of consumer products fabricated using this method.

·Automotive Product Manufacturing

Essential automotive components such as gears, cylinders, small engines, glad-hands, and specific parts find their genesis through the die-casting process.

·Aerospace Part Fabrication

For the aerospace industry, die casting serves as a cost-effective avenue to create lightweight yet superior-quality metal components adhering to stringent quality standards.

Tips to Create the Best Products from Metals Die Cast

Die casting is an important part of the product manufacturing process today. With the metal die cast method, or die cast steel method, you can create various metal items, hardware components, or objects made from die cast metals. However, to achieve the best result from the die casting process, you need to follow the best practices of performing the die casting method. Here are some tips to create the best products from die casting metals:

● Create a precise design for your component.

The design of the mold for the die casting process needs to have precision and accuracy, even more so if you are creating complex die-casting components. Double check your mold design before starting the die cast process to avoid any mistakes during the production phase.

● Use durable metal molds.

It’s best for you to avoid using weak metal molds, such as the ones made from aluminum. You need to use durable metal molds if you want to produce in high volumes. Steel molds are the best recommendation for you, also you need to have a reliable metal molder die cast factory who can help for metal molds.

● Test the metal alloys first.

The molten metal alloys you are using for the die casting process will affect the result of your production phase. It’s best for you to check the metal alloys first to confirm whether they are fit for large-scale productions.

● Avoid undercuts.

It’s also best for you to avoid using undercuts in your design, as it will add more costs to the overall die casting process. The reason is that undercuts will require a special casting process to accommodate the undercut designs, which can get very expensive for tool building and rapid manufacturing.

Cost Factors in Die Casting

The cost of die casting varies based on several factors:

· Comparison with other manufacturing methods (e.g., CNC machining).

· The volume of parts required.

· Die casting steps and setup costs for mass production (e.g., CNC jigs vs. die-cast tooling).

Die Casting Costs

Initial die-casting establishment costs are high, primarily due to complex and expensive tooling designed for robustness. Therefore, die casting might not be suitable for rapid prototyping, but for low-volume manufacturing can be available by rapid tooling method. For moderate to high-volume production, die casting can offer cost efficiency, reaching a "sweet spot" where tool amortization aligns with production costs.

Depending on the projects that you need to complete, you can use various die cast metals in the die casting process. Each die cast metal alloy will offer you their own advantages, so you need to use the right metal for the right purpose and metal molder die casting factory. For the best die casting results, it’s best for you to ensure that the mold design and metal alloys you are using for the die casting process meet the best production standards.

High-pressure Die Casting Services at TEAM Rapid

At TEAM Rapid, a prominent High-Pressure die casting Supplier, our commitment revolves around delivering top-notch die casting, tooling, and CNC machining services leveraging cutting-edge machinery and processes. Specializing in aluminum and zinc alloys, our dedicated team of engineers ensures the economical production of high-quality parts.

Investing in state-of-the-art machinery and technology stands as a testament to our pursuit of process consistency, precision, and reduced labor. Our experts merge automated processes with their extensive knowledge to guarantee clients receive the utmost quality work.

We excel in crafting durable, precise, and consistently high-quality high-pressure die casting parts, catering to diverse industrial applications. Industries benefiting from our services span automotive manufacturing, electronics, architecture, construction, EMI shielding, HVAC, fixtures, plumbing, furniture, and industrial manufacturing.

By prioritizing advanced technology, expertise, and a commitment to quality, TEAM Rapid stands as a reliable partner for all your high-pressure die-casting needs across a spectrum of industries.

FAQs about Die-Casting

1. Why Is it Called Die-Casting?

Die casting earns its name from the utilization of dies. These dies, crafted from steel molds primarily through CNC machining, facilitate the injection molding of liquid metal. They consist of two halves: the fixed half, stationary and connected to the casting machine, and the ejector half, movable for the casting process.

2. What Is the Difference Between Sand Casting and Die Casting?

Sand casting and die casting are pivotal in metal fabrication, differing primarily in mold formation. Die casting employs metal molds, whereas sand casting uses molds crafted from sand. Additionally, die casting focuses on non-ferrous, low-melting-point metals, while sand casting supports a wider range of materials.

3. What Is the Difference Between Injection Molding and Casting?

While both die casting and plastic molding involve injecting molten material into a die to cool, they differ in the materials used. Injection molding utilizes materials like ABS, polypropylene, TPU, and polyethylene, while die casting is tailored for low-melting-point metals.

These distinctions highlight the nuanced differences between die casting, sand casting, and injection molding, outlining their respective mold materials and supported material types for fabrication.