CNC Rapid Prototyping for Low Volume Production

CNC rapid prototyping is a innovation rapid manufacturing method to create rapid prototype. It is an alternative that enables quick prototypes with excellent performance and dependability. Because it produces results consistently and can be completed quickly, this procedure is quite popular in the prototyping industry. CNC machining is the preferred choice for low volume CNC machining production and rapid prototyping for several strong reasons.

Advantages of CNC Rapid Prototyping

1. CNC rapid prototyping is fast

CNC, there are many advantages including speed for faster prototyping. This method allows for fewer materials and quick parts. This is important because, in today’s competitive market, it allows you to launch your product ahead of competitors. Reducing the time it takes to deliver your product will help you attract more customers and increase sales.

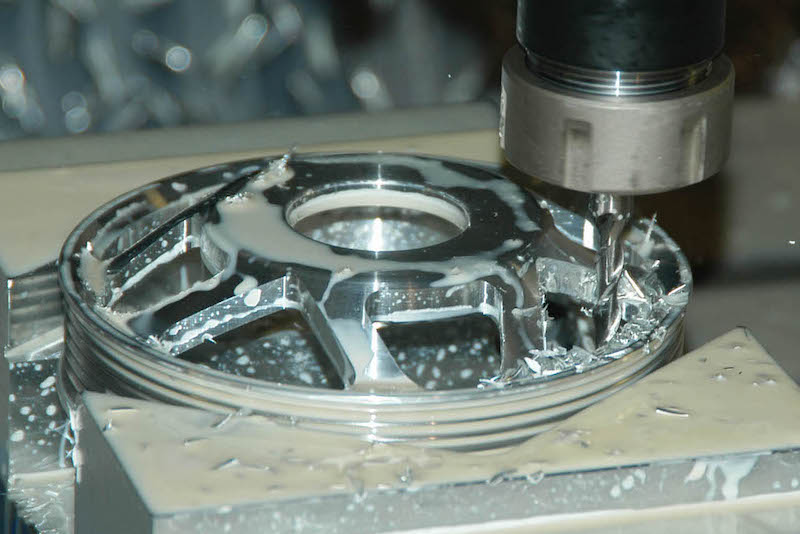

2. There are no fixed tooling required on CNC rapid prototyping

In contrast to conventional manufacturing methods, CNC rapid prototyping eliminates the need for fixed tooling. The hardened metal cutting inserts that are utilized in the spindles are the sole tools required for CNC milling and CNC turning. This saves money and lead time by doing away with the requirement for an expensive and time-consuming tooling setup. It is also possible to make design or structural improvements with more flexibility when there is no fixed tooling, which cuts down on the time and effort needed to iterate and improve the prototype.

3. CNC rapid prototyping is accurate

When prototyping, accuracy and precision are essential. A typical tolerance of +/-0.05 mm can be attained by CNC machines, guaranteeing extremely precise and specification-compliant products. This degree of accuracy lets you trust the prototype's performance and functionality without sacrificing quality. Accurate prototypes are crucial to test and validate designs and make sure that any necessary alterations may be made before proceeding with production,

4. CNC rapid prototyping is easy to change

The ease of modification of CNC prototyping is one of its main benefits. CNC machines give you the flexibility to modify the prototype to fit your needs, be it changing the design or the part's structure. The development process can be accelerated by using the prototype's easy modification feature to make iterations and improvements more quickly. Furthermore, a variety of material alternatives are available with CNC quick prototyping, so you can select the materials that best fit the unique requirements of your product. Because of its adaptability, you can make prototypes that faithfully mimic the final product's appearance and functionality.

10 FAQs Your Need to Know Before CNC Rapid Prototyping

1. In what ways might low manufacturing benefits (time and cost reductions) be realized through CNC fast prototyping?

At lower labor levels, CNC rapid prototyping has several advantages, such as time and cost reduction. Computer machines can automate manufacturing processes, eliminating the need for human intervention and reducing labor costs. Also, the accuracy and speed with which CNC machines can produce sophisticated products provide a shorter time to market, and less repeat production. The ability to rapidly prototype products and products for manufacturers is capable of programming while avoiding expensive mechanical modifications and rework. Considering all the potential savings through early detection of defects, rapid CNC prototyping facilitates simple rapid manufacturing, allowing businesses to get things off to a fast and inexpensive start.

2. How does CNC rapid prototyping ensure high-quality products for low production volumes?

CNC rapid prototyping uses advanced computer-controlled machinery to ensure high-quality production for low-quality materials. These machines provide precise control over the manufacturing process, resulting in consistent and accurate production of parts and products. Using computer-aided design (CAD) software, manufacturers can create detailed and complex drawings, which can be translated into precise instructions for CNC machining. This ensures that every product meets the information and tolerance requirements. In addition, CNC machines can process a wide range of materials, including metal and plastic composites, for material selection flexibility for low-volume production and low volume manufacturing services. CNC rapid prototyping enables manufacturers to always reach desired quality standards, ensuring customer satisfaction and reducing the risk of end product defects or failures

3. Which factors should be taken into account while selecting CNC quick prototyping for small-scale manufacturing?

There are several important factors to consider when choosing CNC rapid prototyping for low-volume production. First, it is important to determine the accuracy required and the complexity of the design. CNC machines are suitable for applications requiring durability and accuracy because they are efficient in producing complex and accurate parts. Second, material selection is important because CNC machines can work with a variety of materials, each with certain characteristics and limitations. When selecting materials, manufacturers must balance factors including availability, durability, and cost against material requirements. Other important factors include funding, timeline and scope. It is crucial to select a CNC quick prototyping service provider with features that are reasonably priced to make sure the solution selected satisfies the project's unique needs.

4. How does CNC rapid prototyping enable low-volume production customization and flexibility?

CNC rapid prototyping provides customization and flexibility options ideal for low-volume production. With the ability to quickly and precisely manufacture parts and components, manufacturers can easily adapt to customer requests or tailor programs to specific needs CNC machines can deliver materials types that have been used, allowing manufacturers to choose products that are more suited to their clients and aesthetics. Additionally, CNC machines can create complex geometries and sophisticated shapes, enabling unique customized products that would be difficult to achieve using traditional manufacturing methods CNC rapid prototyping with ease is also extended to systematic analysis and iteration. Designers can easily manipulate digital models, allowing for rapid prototyping and testing of design iterations, resulting in a customized final product.

5. How does CNC rapid prototyping reduce low-volume production?

CNC rapid prototyping significantly reduces downstream waste in manufacturing due to its precisely controlled manufacturing process. Unlike traditional manufacturing processes, CNC machines eliminate this dependence on digital design, resulting in less waste. The accuracy and precision of CNC machines ensure that only the necessary quantities of material are removed, reducing scrap and minimizing overall waste. Furthermore, CNC allows rapid prototyping for complex designs and complex geometries that generally require fewer resources compared to traditional manufacturing processes. The ability to f also reduces the chances of defective or unsatisfactory production and reduces waste. Again, CNC rapid prototyping provides a sustainable approach to low production, reducing environmental footprint and promoting the efficient use of materials.

6. What are the limitations of CNC rapid prototyping for low-volume production?

There are several restrictions to take into account, even though CNC rapid prototyping has many benefits for low-volume production. First, the size of CNC machines is limited, both in terms of the machine's overall dimensions and the volume of work it can accomplish. Larger components could need different processing methods or specialized machinery. Second, large-scale production demands might not be met by the manufacturing speed of CNC machines. When mass production is not the primary goal and accuracy, personalization, and flexibility are prioritized, CNC rapid prototyping works well in low-volume production. Finally, scalability in tiny or low-cost projects may be limited by the exorbitant cost of CNC equipment and related software. Producers who find that these factors significantly restrict their minimum volume requirements should take these limitations into account and explore other options.

7. How does CNC rapid prototyping contribute to faster time to market for low-volume production?

Low-end manufacturing's time-to-market is accelerated in large part by CNC quick prototyping. Traditional manufacturing techniques can include costly and time-consuming mold or machinery processes. However, CNC machines do not require injection molding or rapid tooling because they can produce parts and components straight from digital models. This enables producers to quickly develop and test items, find flaws or opportunities for improvement, and make the required changes before going into production. The speed at which a system may be swiftly replicated and real-world testing carried out greatly shortens the time required for product development and optimization. Furthermore, businesses can quickly adapt to shifting consumer or market demands thanks to CNC rapid prototyping, giving them a competitive edge in terms of quicker time to market and lower production quantities.

8. How does CNC rapid prototyping increase low-volume production design flexibility?

Low manufacturing rates using CNC rapid prototyping maximizes the freedom of design, enabling the creation of complex systems that would be difficult to manufacture with traditional manufacturing processes CNC machines can produce geometry that accurately simulate the complex materials, producing high-quality materials that conform to desired structural specifications. Because CNC machines can create parts from composite, metal, and plastic materials. This allows producers to select the ideal materials for their goods based on both aesthetic and functional needs. Additionally, CNC rapid prototyping makes design iterations and optimizations easier. To ensure that the finished product meets specifications and design specifications, manufacturers can quickly adopt digital systems and create prototypes for testing and certification.

9. How does CNC rapid prototyping reduce the risks associated with low-volume production?

CNC rapid prototyping provides a cost-effective and efficient way to control processes and ensure quality, reducing the risks associated with low volumes. Rapid prototyping is so accurate that manufacturers can quickly identify design flaws or design problems, reducing the risk of faulty or substandard products Ability to test and certify prototypes rapidly enables necessary and efficient changes, reduces the chances of expensive rework or recalls or can quickly respond to change customer needs, the risk of being left behind by competitors reduced Using accelerated CNC prototyping, manufacturers can reduce the risk associated with low productivity, ensuring product quality, customer satisfaction and overall business success.

10. How does CNC rapid prototyping improve the cost-effectiveness of lean manufacturing?

CNC rapid prototyping improves cost-effectiveness in low-volume production with a variety of materials. First, eliminating molds or manufacturing tools reduces upfront costs, making rapid CNC prototyping uneconomical for manufacturing processes with low materials. Second, the ability to produce prototypes quickly and accurately allows manufacturers to quickly identify and address design deficiencies, avoiding major changes or rework during the production phase. Manufacturing costs are reduced, and the risk of product failure or recall is reduced. Additionally, CNC rapid prototyping reduces waste, as the process eliminates the dependence on digital design, resulting in less waste. This helps to reduce costs in terms of resources and associated costs. By streamlining the process and reducing the risk of errors or rework, CNC rapid prototyping provides a cost-effective solution for simple manufacturing.

Contact TEAM Rapid

TEAM Rapid offers CNC Prototyping to meet your low volume production needs. No matter 1 part or 10,000 parts we can offer the best solution for you. Want to know more about us? Contact our team at [email protected] today and get a free quote!