July 14, 2021 February 20, 2023

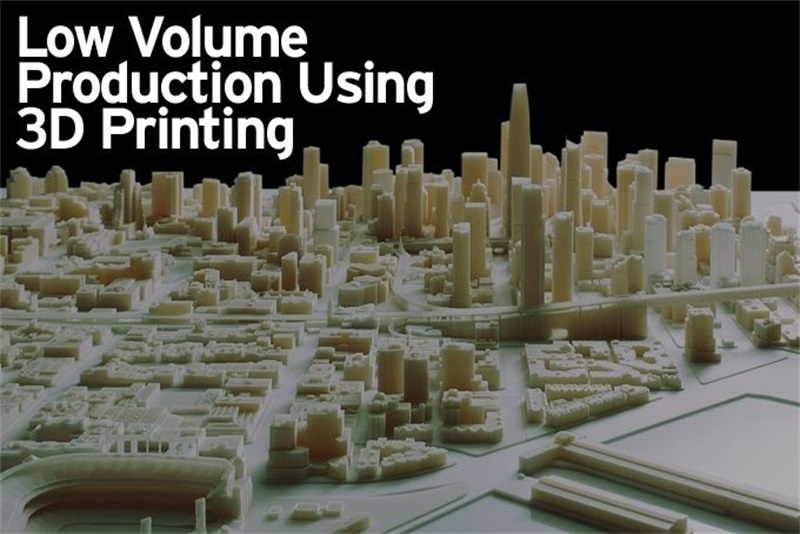

If you are a new manufacturer in 3D printing industry, we would suggest do not rush to buy the 3D printing machines as some 3D printers are too simple or lack of important features for your manufacturing requirements. 3D printing low volume production is used for rapid prototyping and actual manufacturing. 3D printing allows free …