Fasteners are several parts of the machine. Fasteners can be big or small. Fasteners are joined in different ways based on their role and position in a machine. The fastener is used to describe a wide range of tools, there is a range of types of fasteners. The purpose to use fastening is to mechanically adhere to the items. Simply, fasteners are used to hold parts together mechanically. Some people may think glue can do the same job effectively. This helps to expand the initial definition. Hardware fasteners help to hold the parts together mechanically.

There are wide classifications of types of fasteners. Fasteners can be classified into permanent and non-permanent fasteners. Fasteners are considered to be joints that are non-permanent. That means two separate parts can be connected with a fastener. When the part is apart, it will not suffer any form of damage. A rivet is an exception; a rivet is a permanent fastener. Using the fasteners with formed thread correctly can offer a reliable hold on the parts. You can be sure that your parts are subject to a high level of stress. They are versatile and useful for a wide range of types of fastening.

The fastening process is to hold different parts of a machine together. Fasteners are important in creating several items. For example, if you do a DIY project, it is possible to use fasteners to complete your job. Fasteners help to hold the parts in place while avoiding excess vibration and pressure. There are many different types of fasteners which include nuts, bolts, screws, keys, washers, rivets, anchors, studs, inserts, rings, pins, and more. Today, we will discuss the different types of fastening and their subtypes. We will also share some tips on how to choose suitable fasteners for your jobs.

Table of Contents

Common types of fasteners

There are many different types of mechanical fasteners. There are many subtypes available of those types of fasteners to choose from. Here are the most common types of fasteners:

Bolts

Bolts are used to hole unthreaded parts together. They are the most common type of fasteners, and there are many different types of bolts can be chosen and used.

Screws

Screws are versatile fasteners. Screws have durable holding power. The structure of the screws is similar to the bolts. Unlike bolts, screws do not need anything to keep them in place.

Nuts

A nut has an internal thread that works with a bolt to hold the object together.

Washers

Like an annulus, washers are small and in circular shape. Washers work together with nuts and bolts. They serve important fastening functions.

Rivets

Rivets are permanent fasteners that secure different types of components.

Different types of fasteners

There are many different types of fastening. Each of them works for specific types of applications. To choose the correct types of fasteners, understanding the unique uses of each type is a must as this helps you to know which fasteners to use for your application.

Types of bolts

Bolts are the common fastener to hold unthreaded parts together. There are many different types of bolts can be chosen and used, a bolt has external threads on one of its ends. There is also a hexagonal head on the other end. To fasten the required part together, a bold work together to a nut. In some projects, a part with a threaded hole replaces the nut. This minimizes the parts used. Bolds are the most commonly used type of fastening. Here at TEAM Rapid, there are several types of bolts for applications. For example:

1, Types of Fasteners – Hex-head bolts

Hex-head bolts have heads in a hexagon shape. The six sides of bolts offer a good granularity of angles from which people can approach the bolt. When you want to fasten the bolts to a spot that is difficult to reach, this is important. Hex-dead bolts are used in machining as they assemble and dissemble easily.

2, Types of Fasteners – Double end bolts

Double-end bolts have a similar look as threaded rods. There is a thread at the end of double-ended bolts. So, double-end bolts can work with a nut at one or both ends.

3, Types of Fasteners – Eye bolts

There is a loop at one end of an eye bolt and a thread at the other end of an eye bolt. Depending on the machine size and design, the work of the loop is different.

4, Types of Fasteners – Carriage bolts

Carriage bolts have a convex metal head, square necks, and threads. Carriage bolts can fasten the wood materials. By using pressure, carriage bolts can fit into a square neck into a wood piece easily. So, carriage bolts have self-locking potential.

5, Types of Fasteners – Socket head bolts

Socket head bolts are also called Allen bolts. There are cylindrical heads and hexagonal hold on the socket head bolts. Socket head bolts can fasten to components by an Allen wrench.

6, Types of Fasteners – U – Bolts

U-bolts have a shape like horseshoes. Then a bent section of U – Bolts don’t have a thread. U-bolts have threads on the straight end all the way. When it comes to holding tubes and pipes without holes, U-bolt is an ideal option.

Types of Fasteners: Fastening screw

The screw type has a similar structure as bolts. The thread starts from the tip. Their heads can be in different shapes. A screw needs internal threads to hold objects together. Bolts can maintain grip between unthreaded parts with nuts.

Screws are self-threading. Screws can make thread into the parts during installation which can avoid the need for the previous tapping. There are several designs for screws available. Each of them has its usefulness.

1, Types of Fasteners: Self-drilling screws

Self-drilling screws are also called self-tapping screws. They build internal threads in installation. There are threaded shafts from the tip to the head. Self-drilling screws create space in the parts during turning easily.

2, Types of Fasteners: Sheet metal screws

Sheet metal screws have a sharp cutting thread that can cut sheet metal, wood, or plastic. Their shank is threaded with a notched point which allows chip removal.

3, Types of Fasteners: Machine screws

Machine screws are commonly used in machinery works. Similar to sheet metal screws, machine screws are installed into pre-drilled holes. It is unnecessary to make a hole during installation.

6, Types of Fasteners: Hex lag screws

Hex lag screws are large wood screws that help heavy-duty applications in machinery and wood operations.

7, Types of Fasteners: Deck screws

Deck screws allow installation into wood materials easily. The stripping effects can be eliminated by the square drive and bugle head.

8, Types of Fasteners: Wood screws

There is threading with smooth shanks in wood screws. Wood screws slide through the wood and pull the board together easily.

Types of Fasteners: Nuts

A nut works together with a bolt of the same size. Nut offer improved grip and increased torque to users. There are various types of nuts which include the following:

1, Cap nuts

Cap nuts have closed ends which are like a dome. The closed end makes sure the bolt-nut connection is protected. It also offers a good finish to the object.

2, Castle nuts

Castle nuts have notches at their ends. This allows the insertion of pins through notches. If low torque is required, castle nuts are the best used.

3, Types of Fasteners – Weld nuts

Weld nuts fasten object parts in hard-to-reach areas. They need welding onto the surface of the object.

4, Hex nuts

Hex nuts are the common types of nuts. They are low cost and can be assembled by using a wrench easily.

Type of washer

Washers are used with nuts and bolts. They are placed under joints, nuts, and axle bearing. Washers can reduce friction and eliminate leakages and isolate different components. A washer can avoid the loosening of objects because of vibration.

1, Plain washers

The plain washer isolates parts from nuts and bolts. They protect the surface of the object. They increase the surface area and distribute the load on the material.

2, Spring washers Types of Fasteners

Spring washers are in circular shape with a bit of modification. They make joints more elastic

3, Locking washers

Locking washers lock nuts and bolts even if there is friction or vibration. Most people like using sprint washers.

4, Dock washers

Dock washers are heavy-duty washers that build docks. Dock washers are useful in heavy-duty construction if thick washers are needed.

Types of Fastener: rivets

Rivets are popular types of fastening. Rivets secure a wide range of materials and offer support against shearing force. Rivets are lightweight. A rivet has a head on the end to support axial loads. To install rivets, it is necessary to use threads. Rivets are preferred in the aerospace industry. The types of rivets include:

1, POP rivets

POP rivets have a hat and a mandrel. POP rivets can be open-end, closed-end, and countersunk.

2, Multi-grip rivets

When the installed materials have variation, a multi-grip rivet is an ideal option. The multi-grip rivets expand to the needed size and hold the objects together.

3, Tri-fold rivets

Tri-fold rivets have three cuts in their hats. The hat folds outwards and provides strength and handing power.

4, Large flange rivets

Large flange rivets have larger washers on their hats. These connect the materials efficiently and quickly.

How to choose suitable Types of fasteners?

1, Understand the application

Choosing the fasteners depends on the requirement of the application. Before making decisions, you need to consider if the fasteners fit the application. The design of the fasteners is important. You may need a long flange bolt to hold components of your parts. Leaving some thread of the fasteners out is also a consideration. This makes sense that the safety of the material. In some cases, you may need more than one type of fastening. In this case, you must find an experienced expert like TEAM Rapid to make decisions.

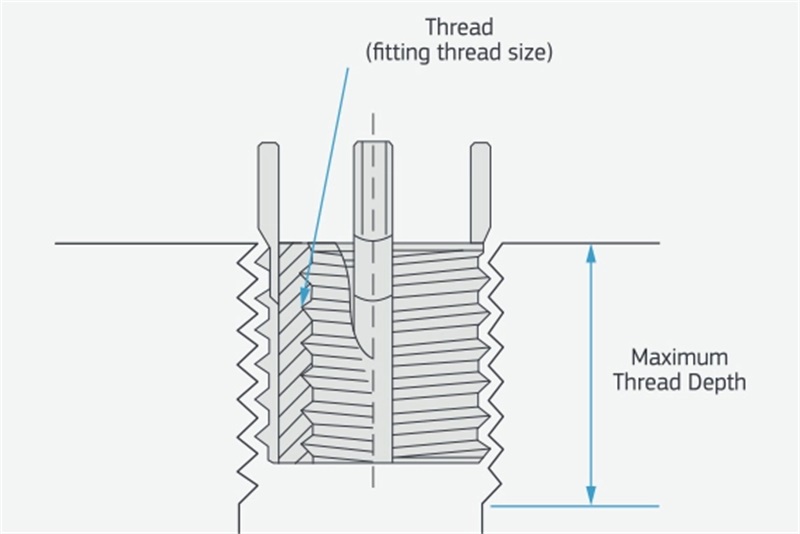

2, Select the correct thread Types of Fasteners

Thread selection is also an important thing when choosing types of fastening. Threads are an important part of an application. Thread can be UNF, UNC, and eight-thread. UNC ensures the quick assembly of components. Fine thread needs a longer time to assemble. A coarse thread provides better thread engagement. They also make sure of a secure connection. Choosing the thread to provide the best load-handing capabilities is what you need to do.

3, Consider the materials for construction

Many different materials are used in creating mechanical fasteners. Carbon steel is the most used material as it is strong and workable. Alloy steel and stainless steel are also common materials used to make fasteners. They are strong but brittle. Stainless steel has specific properties for special use. Bronze, brass, and aluminum are also used as well. They are corrosion-resistant. The best types of fasteners are made with hard material to eliminate stripping or galling.

4, Think about the type of exposure to the fastener

Before making the decision to choose a fastener, the temperature which will expose the fastener is a consideration. Extreme temperature changes may lead to expansion and contraction of fastened joins which will create a loose connection. The vibration is also an important consideration. Here at TEAM Rapid, choosing suitable fasteners for your projects is easy. Our experienced experts have the expertise and rich knowledge of fastening. Contact us today.

Conclusion

Here at TEAM Rapid, we offer a wide range of high-quality rapid manufacturing fasteners. For your project and applications, you can trust us to find a fastener that meets your needs. At TEAM Rapid, our experts provide you with guidance that helps you to find the right types of fastening for your projects. We offer excellent services, and fast turnaround at a competitive cost. Contact us today to get a free instant quote.