In the manufacturing industry, galvanized sheet metal is a common sheet metal type. You will be told by steelmakers or steel manufacturers that galvanization provides the best protection from corrosion. In fact, there are many interesting things that you can know from galvanized sheet metal.

Table of Contents

What is galvanization?

Galvanization is a manufacturing process that applies zinc coating to steel to prevent it from rusting. The zinc coating protects the metal base. It acts like a barrier to the corrosive elements. So, it offers a sacrificial nature that offers high-quality and long last sheet metal fabrication parts.

Galvanized sheet metal is a steel or iron product with a protective zinc coating to prevent rusting. Galvanized offers corrosion protection, durability in harsh conditions, a long lifespan, availability, versatility and sustainability, and formability. The versatility makes galvanized sheet metal has a wide range of applications. It is beneficial to use galvanized steel. Before using galvanized steel, it is important to understand the principle of galvanization works.

How to galvanized sheet metal?

1, Electrogalvanizing

Electro galvanizing is a process when a layer of zinc is boned to stainless steel by electroplating when a fabricator runs a current of electricity by a saline and zinc solution with a zinc anode. During the electro galvanizing process, the polarized electrical device is a steel conductor. Electro galvanizing provides a lower thickness deposit for comparable to increase performance compared to hot-dip galvanizing.

2, Hot-dip galvanizing

Hot-dip galvanizing is a popular way to galvanized sheet metal. It submerges metal in molten zinc to protect the metal. Hot-dip galvanizing happens in below three ways:

A. When the zinc coating is intact, it prevents corrosive substance from reaching the steel or iron

B. Hot-dip galvanizing acts as a sacrificial anode. Galvanic cathodic protection protects buried or submerged metal from corrosion, and the exposed steel or iron is protected by the remaining zinc.

C. The zinc protects its base metal by corroding before iron.

Hot-dip galvanizing prevents iron or steel from being exposed to nature which protects it from corrosion and oxidation. Hot-dip galvanizing is economical. It is performed in minutes and covers the areas which are hard to reach.

3, Metallic/thermal spraying for Galvanized Steel metal

Metallic spraying is a process to cover sheet metal parts with a metallic coating by a spray of molten particles. The molten particle does not heat the surface as the heat of a particle is proportional to its size.

4, Flame and arc spraying

Flame and arc spraying are sub-methods to add anti-corrosion layers and thermal barriers. Spraying increases durability, wear resistance, and modified electrical properties, and protects them from being damaged.

5, Sherardizing

Sherardizing is also known as vapor or dry galvanization. Sherardizing involves heating steel up to 932 degrees in a closed rotating drum which contains metallic zinc dust and inert filler like sand.

If the temperature is above 572 degrees Fahrenheit, the zinc dust evaporates and diffuses into the steel substrate to form a diffusion bond.

Sherardizing is great for small sheet metal parts and products which need a coating of the inner surface because the product should be smaller than the rotating drum. No hydrogen is involved in this sheet metal technique. So, hydrogen embrittlement is excluded.

If you are ready to inquire about galvanized sheet metal for your projects, contact our sales specialists at TEAM Rapid today. If you want to learn more about sheet metal products, continue to read below.

How does galvanization provide protection of base metal?

Binding the steel and zinc together permanently to give a rust-resistant version of the base metal is the basic principle of galvanization. As mentioned, there are various galvanization types, each with its unique principles.

Galvanization works on the following principles:

1, The zinc coating prevents corrosive substances like acid from reaching the base metal

2, Zinc sacrifices its anode more readily compared to the base metal when the coating is scratched. So, it offers full protection from rusting.

3, Zinc corrodes quicker than base metal. This activity is a good way to protect the base metal as the purpose is to allow zinc to rust before the metal for enough protection.

An effective galvanization process depends on pretreatment and post-treatment. If the pretreatment is inefficient, it will not allow the molten zinc to reach the steel for a great galvanized film. If the post-treatment process is not efficient, it will compromise the appearance of the galvanized film which reduce the value of components.

Different types of galvanizations

There are many different galvanization types to protect products from corrosion. Each type has its performance and characteristics.

1, Hot-dip galvanization for galvanized sheet metal

Hot-dip galvanization is the widely used galvanization method. It involves the dipping of the steel in molten zinc. The molten zinc maintains a temperature of 460℃. When the base metal is cleaned chemically, the residual oxides are eliminated. Between the zinc and the intended metal, a metallurgical bond starts to form. When pulling the metal from the bath, the zinc mixes with oxygen from the atmosphere to form zinc oxide. Reacting with carbon dioxide, the zinc oxide form zinc carbonate. The zinc carbonate creates the coating on the base metal. There is a pattern like crystalline on the surface of galvanized metal. Hot dip galvanization is a simple and economical method.

2, Electro galvanization

Instead of using a molten zinc bath, electro galvanization uses an electrical current in an electrolyte solution to transfer the zinc ions into the metal. It is precise and uniforms coating thickness.

3, Galvannealing

Combined with the hot-dip galvanization and annealing, galvanizing creates galvanized steel with some special coating. Both hot-dipping and annealing happen immediately. So, if you want to create parts with a matte gray finish, galvanizing creates galvanized sheet metal that can withstand welding and is conducive to paint adhesion.

4, Pre-galvanization

Pre-galvanization is similar to hot-dip galvanizing. Pre-galvanization performs at a steel mill on materials that have specific shapes. Pre-galvanized metal sheets are rolled by a clean agent to prime the material for galvanization fast.

Applications of galvanized sheet metal

There is a wide range of applications of galvanized sheet metal. It helps to create part of both small and large machines via rapid manufacturing. Galvanized steel can build parts that are able to withstand harsh conditions.

1, Automotive industry

Dating back many years, galvanized steel is used in the automotive industry. Zinc-coated bodies on automobiles are commonly used in car manufacturing. The rust-resistant nature of galvanized sheet metal makes it a great tool in the market as it offers anti-rust warranties to customers.

2, Telecommunication industry

It is not an easy job to maintain phone lines. It needs the toughest and most reliable materials. Galvanized sheet metal provides phone wiring and equipment boxes with its uses. So, the danger of injury is decreased and maintenance cost is reduced.

3, Electric equipment

Just look at the electric appliance, you may notice the unique feature of casting. Most castings use galvanized steel material. In fact, some interior parts of electric equipment are made from galvanized sheet metal materials.

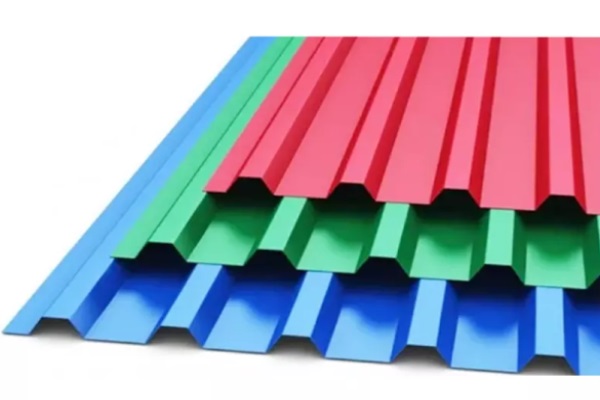

4, Building and construction industry

As galvanized sheet metal has great sturdiness and durability. It is popular in the building and construction industry. Galvanized sheet metal is widely used in various commercial and residential projects. Galvanized sheet metal is also a good choice for aesthetics. It offers modern architectural design. It is an ideal material for both small and large construction works.

Advantages of galvanized sheet metal

A galvanized sheet metal is corrosion-resistant. It is tough and long live. It is suitable for a wide range of applications.

1, galvanized sheet metal is Durable

The galvanized steel provides durable corrosion protection. With a zinc coating, the steel structure is protected for a century. The thickness of the coating meets the needed corrosion performance in many applications.

2, Reliable coating

The coating on the steel is consistent and specified. Galvanized steel provides reliable protection from corrosion. The process is replicable because of the natural metallurgical reaction. The resultant galvanized costing provides protection to the steel for a long time.

3, galvanized sheet metal is Cost-effective

The two main factors that affect the cost of steel protection are the initial cost and the lifetime cost of protection. Galvanization provides a high-performance cost so there is no need to paint the steel for a long time. As galvanization costs are constant, painting costs are increasing over the years. The initial cost of galvanized sheet metal is low and the steel can be used immediately when delivered.

4, Quick turnaround

Here at TEAM Rapid, we can get your steel galvanized in a short period. It will not cost us too much time to galvanize the steel. When the steelwork is ready, we will complete the jobs in 24 hours. The preparation is thorough but it does not take too much time. Our process is straightforward and quick.

5, galvanized sheet metal is Complete coverage

The bond between steel and steel is strong. The coating can last for generations. It increases the strength of the steel and there is superior coverage. This makes sure that the galvanized sheet metal is protected and they are vulnerable.

Conclusion

Galvanized metal offers a wide range of advantages which are ranging from corrosion resistance to durability. Galvanized sheet metal is applicable in many industries. If you want sheet metal material with the best rust protection, galvanized sheet metal is an ideal option. Here at TEAM Rapid, we provide cost-effective and on-demand sheet metal prototyping services. We create high-quality low volume prototypes and high-volume productions. Simply upload your design file and requirements to get an instant free quote today. We offer professional DFM analysis. We have a one-time delivery and outstanding manufacturing capabilities. We always offer the most competitive price.