Have you ever been curious about the process behind the creation of the sleek? No matter metallic parts of your favorite tech gadgets or the durable frames of essential machinery. These elements typically originate from a critical and fascinating phase in product innovation known as sheet metal prototyping. This indispensable stage functions as a crucial conduit, transforming initial design ideas into concrete, operational entities. But what entails sheet metal prototyping, and why is it so integral to the process of product development? Let’s dive into a thorough exploration of this subject in converting novel ideas into functional solutions.

Table of Contents

- 1 Looking into Sheet Metal Prototyping

- 2 The Value of Sheet Metal Prototyping in Product Development

- 2.1 Risk Mitigation

- 2.2 And here’s the cool part about Sheet Metal prototyping

- 2.3 Cost Reduction

- 2.4 Accelerated Market Launch

- 2.5 Stakeholder Involvement

- 2.6 Choosing the Perfect Mix of Materials and Craftsmanship in sheet metal prototyping

- 2.7 Design Tailoring and Flexibility

- 2.8 Market Insight by sheet metal prototyping

- 2.9 Regulatory Assurance

- 3 Unlock high-value sheet metal prototyping services with Team Rapid Tooling today

- 4 Conclusion

Looking into Sheet Metal Prototyping

Sheet metal prototyping is like the artistry behind the scenes. Metal sheets get a total makeover into the shapes and forms needed for the next big thing. They are parts of a gadget or the whole enchilada. Think of it as using a mix of cool moves—cutting, bending sheet metal, punching, and piecing together. To whip up prototypes that look and feel just like what you imagined the final product would be. Prototypes are more than just attractive faces; they serve as the dress rehearsal for the big event, giving an idea of the design’s feel, functionality, and readiness for a stylish runway debut.

Selecting the material is like picking out the ideal dress for a banquet. Aluminum, steel, brass, copper, and titanium are among your standard materials. Each adds a special twist to the combination with its strength, power, conductivity, and allure. Making sure the finished product fulfills its purpose well. It also makes a statement that captivates everyone focusing on what attracts the eye.

The Value of Sheet Metal Prototyping in Product Development

Far from being just another manufacturing step, sheet metal prototyping is a foundational pillar supporting innovation and efficiency in product development. Its significance can be highlighted through several aspects:

Risk Mitigation

Implementing rapid prototyping at the outset of the design process allows a business to detect and rectify possible defects, dramatically diminishing the risk of expensive errors when the product goes into mass production. Let’s say a cellphone maker spots a glitch with the battery size while they’re still in the prototype stage. This is their golden chance to tweak things before they start churning out millions of phones and dodge a massive recall headache.

When it comes to a product that can take a beating, is easy to use, and delivers a top-notch experience. Prototyping is key. Take a furniture company, for example. They might whip up a prototype of a brand-new chair to get a feel for how comfortable and sturdy it is, ensuring it fits perfectly in both the living room and the office.

And here’s the cool part about Sheet Metal prototyping

it’s like a treasure trove of insights that can seriously amp up a product’s performance. It makes a breeze to use, and give it a look that turns heads. A producer of kitchen gadgets, for instance, may refine the design of a blender’s handle. It is based on following feedback from sheet metal fabrication prototype tests to guarantee a more comfortable usage experience.

Cost Reduction

Early detection of design issues through prototyping prevents the need for costly modifications during the later stages of production or post-production. An automobile manufacturer, for example, might prototype a new dashboard configuration and find that altering the placement of certain controls not only reduces manufacturing expenses but also does not detract from the product’s functionality, avoiding expensive changes during mass production.

Accelerated Market Launch

Sheet metal prototype enhances the pace of the design and testing processes. It can lead to a swifter introduction of the product to the market. For example, a technology firm could swiftly prototype and assess a new computer model, allowing for quick adjustments and an expedited launch, potentially outpacing competitors.

Stakeholder Involvement

Prototypes serve as physical examples that significantly improve engagement with stakeholders. A burgeoning drone enterprise could showcase a prototype in presentations to investors to vividly demonstrate the product’s concept and functionality, promoting clearer feedback and facilitating investment decisions.

Choosing the Perfect Mix of Materials and Craftsmanship in sheet metal prototyping

The magic happens during the prototyping phase, where the quest to discover the ultimate blend of durability, resistance to the elements, and featherlight characteristics for the adventure-bound begins. Imagine a company that dreams up outdoor gear. They could be creating an innovative tent, experimenting with various materials to strike that perfect balance. It’s like a culinary experiment, where they mix and match ingredients. Aiming for a recipe that will stand up to the wilds for those who tread the trails.

Design Tailoring and Flexibility

The adaptability of sheet metal prototyping allows for the accommodation of unique and sophisticated design requirements. A boutique motorcycle shop could employ prototyping to craft a bespoke fuel tank that meets a client’s specific needs.

Market Insight by sheet metal prototyping

Prototyping for market testing offers valuable feedback on a product’s design and practicality. Companies that build prototypes are focusing on wearable technology might use prototypes of a new activity tracker in focus groups. Feedback on its appearance, features, and user interface, informing adjustments are important before final production.

Regulatory Assurance

Prototypes are necessary in some industries to go through regulatory assessments and receive approvals. Imagine a company that’s all about creating medical gadgets is working on a shiny new surgical tool. Before this tool can make its grand entrance into hospitals and clinics. They’ve got to whip up a prototype and give it a thorough check-up. They’re making sure it ticks all the boxes for safety and quality standards, kind of like getting a seal of approval before it steps into the operating room.

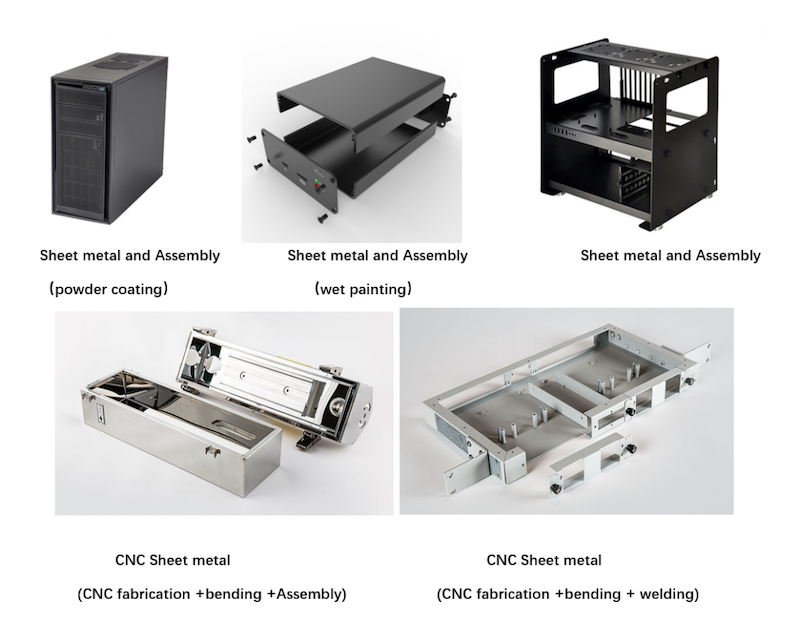

Unlock high-value sheet metal prototyping services with Team Rapid Tooling today

We provide a wide range of sheet metal prototyping services all at a large scale. Below is a brief case study showcasing our capabilities. A global leader in air technology partnered with TEAM Rapid for a prototype to protect components with minimal vibration. The client appreciated the fast and cost-effective proposal for a durable, high-pressure, and temperature-resistant mold. Utilizing their expertise, TEAM Rapid efficiently completed the process, including CNC machining, EDM machining, and sheet metal fabrication, within 10-25 days. For expert sheet metal prototyping services, contact TEAM Rapid at [email protected]

Conclusion

When it comes to bringing fresh products to life, sheet metal prototyping plays a pivotal role in sparking innovation, boosting efficiency, and paving the way for market triumphs. It makes thorough testing, design enhancements, and risk management easier, resulting in products that are affordable, functional, and in line with market trends and customer expectations. In the dynamic field of product development, sheet metal prototyping exemplifies the transformative journey from visionary concepts to tangible, impactful products. From cutting-edge technology gadgets to essential industrial equipment, the path from idea to realization is made viable through the detailed and transformative process of sheet metal prototyping.