The growing fascination with 3D printing technology has sparked detailed debates about manufacturing and prototype creation. At the heart of these discussions, there is an important question. Could rapid 3D printing surpass CNC milling as the favored technique for rapid prototype production? There are several benefits associated with each strategy, making this a complex problem. Let’s dive into this compelling subject, evaluating both sides and contemplating the advancements on the horizon for rapid prototyping.

Table of Contents

Discovering the Craft: CNC Machining versus Rapid 3D Printing

Envision CNC machining as the seasoned craftsperson in the workshop, diligently sculpting a piece from a solid chunk using an assortment of tools to manifest the intended design. Esteemed for its unmatched precision, CNC machining produces items with an accuracy that is simply astounding.

Contrastingly, 3D printing, the innovative frontier of additive manufacturing, materializes digital designs into physical forms by methodically stacking them layer by mesmerizing layer. Praised for its capacity to effortlessly generate intricately detailed shapes, it’s expanding the horizons of manufacturing possibilities.

The Face-Off

Diving into the nitty-gritty, CNC machining wins hands down in the durability and precision department. Its methodical, subtractive process ensures components can endure the toughest conditions and fit together perfectly. While rapid 3D printing is evolving rapidly, it’s still playing catch-up in producing parts with comparable toughness and exactness. It‘s also especially for items meant to withstand heavy use.

Yet, when it comes to embracing complexity and innovation, 3D printing takes the spotlight. It effortlessly crafts detailed internal structures that would challenge CNC machining, limited by the physical constraints of its tools.

Weighing Speed Against Cost

In the race to develop rapid prototypes or small batches swiftly and economically, rapid 3D printing often emerges as the victor. It eliminates the need for custom tooling, positioning itself as a more streamlined and cost-effective option. However, when the scale tips towards larger volumes, CNC machining becomes more financially viable. Thanks to the spread of its upfront costs over a greater number of units.

The Material Selection Saga

The battle of materials is another critical aspect of this discussion. A wider range of materials, such as sophisticated polymers and other metals are available with CNC milling. The area is where 3D printing is actively attempting to gain traction. In many cases, CNC machining is still the preferred method when the material’s qualities are crucial. So even if 3D printing is making remarkable advances in material science.

Envisioning the Future: Blending and Innovating

Predicting the trajectory of manufacturing technologies doesn’t involve choosing sides between CNC machining and rapid 3D printing. Instead, it’s about foreseeing a blended ecosystem where both play to their strengths to maximize project success.

With even greater flexibility and complexity in manufacturing possibilities promised, the innovation engine powering 3D printing is not slowing down. On the flip side, hybrid manufacturing is opening up new possibilities by merging the top advantages of both additive and subtractive rapid manufacturing techniques. They offer unmatched precision, efficiency, and artistic liberty.

Harmony Over Rivalry

Viewing these technologies as competitors misses the broader picture. Each shines in its own right and for different applications. Embracing the unique advantages of both paves the way for groundbreaking results in the future.

Looking ahead, rapid 3D printing is set to further cement its role in rapid prototyping. It is especially for designs that demand high levels of detail and customization in small volumes. On the other hand, the unbeatable precision, robustness, and extensive material options of CNC machining ensure it remains indispensable for creating durable components and handling large-scale production.

Reasons why CNC machining will continue to be used alongside or instead of Rapid 3D printing

In the world of making things, where new rapid 3D printing techniques are popping up left and right, the good old CNC machining method is standing strong, not just clinging to the past but holding its own as a crucial part of how we build and design today. When you take a closer look at how these two methods work together, you’ll see that CNC machining has some special tricks up its sleeve, especially when things get really specific, like picking the perfect material, hitting the bullseye with precision, or figuring out the best way to make a bunch of something without breaking the bank.

Take the world of airplanes, industrial robot components, and rockets, for example. Here, picking the material for a part isn’t just about how strong or light it is. It’s about finding something that can handle extreme temperatures, resist getting tired out from too much use, and play nice with special coatings that make it even better. CNC machining is a star in these situations, able to work with tough materials like titanium and Inconel that are a must-have for anything flying high in the sky.

Then there’s the high-stakes game of making things super precise, like in medical devices or tiny electronics. In these worlds, being off by even a whisper can mean a device doesn’t work as it should. CNC machining shines here, making parts with the kind of precision that makes sure everything fits and works perfectly, every single time.

As for making a lot of something, rapid 3D printing is fantastic when you’re just starting out or when every piece is one-of-a-kind. But when you need to make more of something, CNC machining can often do it faster and cheaper, especially as you make more and more. Plus, while 3D printing is often praised for not wasting materials, CNC machining can sometimes be the greener choice when you look at how much energy each method uses, especially for making metal parts.

And let’s not forget about the human touch. CNC machining isn’t just about following instructions from a computer. It’s about the skill of the people running the machines, their knowledge of materials. Their knack for getting everything just right. This connection to craftsmanship brings a special something to CNC-made parts, a quality that goes beyond numbers and specs, adding a layer of trust and reliability to the mix.

So, while the buzz around 3D printing isn’t going anywhere anytime soon, CNC machining will continue to be a key player, especially when the job calls for that perfect mix of materials, precision, cost-effectiveness, and that human touch.

Fundamentally, the development of industrial processes isn’t about one approach winning out over another. It’s more about using both of their strengths to form a potent coalition. We’re not just seeing changes with every advancement in CNC machining and rapid 3D printing; we’re also participating in a revolution that’s bringing efficiency, creativity, and innovation to the fields of design and production. We’re heading toward a future where the potential for quick prototyping is endless, enhancing our reality with discoveries that awe and excite, by valuing their cooperation over rivalry.

Leverage high-quality CNC machining and rapid 3D printing services from Team Rapid today

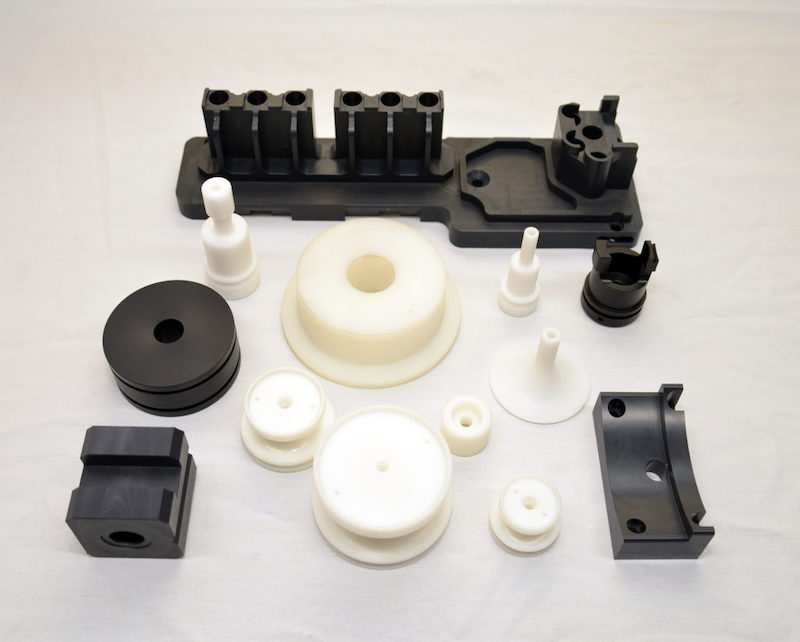

We offer a variety of CNC and 3D printing services and are capable of handling high-volume demands. Below, you’ll find a succinct case study that showcases our expertise. This should demonstrate just how efficient we are at what we do. And it should showcase what we might be able to do for you. Collaborating with an air technology leader, TEAM Rapid developed a vibration-minimizing prototype of a particular type.

The client valued the swift, cost-effective solution that could withstand high pressures and temperatures, completed in 10-25 days. For expert CNC machining and rapid 3D printing services, reach out to TEAM Rapid at [email protected].