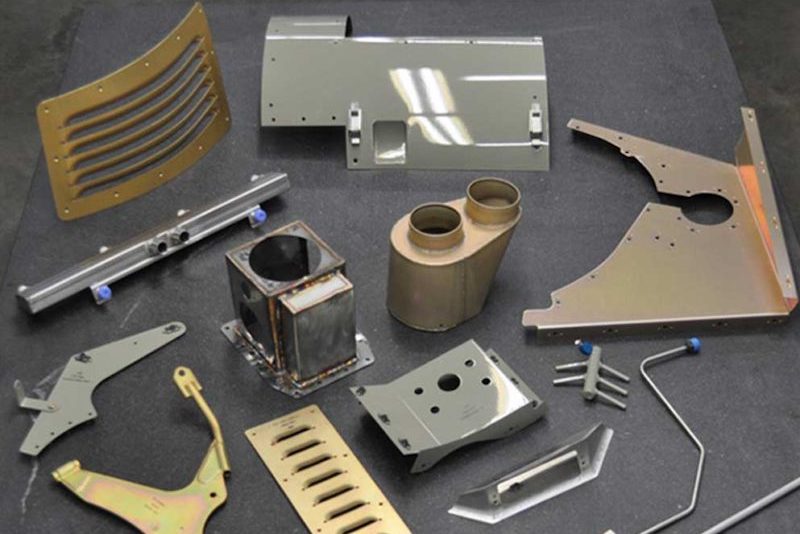

You can process metal sheets and create custom objects with metal sheet fabrications. This manufacturing process gives you the flexibility you need to produce varying components. This article will delve deeper into the industries and applications that use sheet metal fabrication.

Table of Contents

List of Industries and Applications for Sheet Metal Fabrication

Sheet metal fabrication is spreading far and wide in various industrial applications today. This production method is always in high demand. Here’s the list of industries and applications for sheet metal fabrications:

Sheet Metal Fabrication in Railroad

The railroad industry needs custom sheet metal components for the rails and other objects. The trains and cars also need constant supplies of sheet metal components. The railroad companies need different sheet metal specifications depending on their train operations and terrains.

Aerospace

The aerospace industry needs sheet metal components to help lighten the load of their aircraft. Aerospace companies can create durable, lightweight, and cost-effective sheet metal components for their products. Aircraft wings are the most common sheet metal components for the aerospace industry. Sheet metals can also be usable for various structural aspects of the airplane.

Sheet Metal fabrication in Automotive

In the automotive industry, sheet metal forming is commonplace to create vehicle bodies. It provides a lightweight yet durable body structure for the vehicle. Vehicle body panels and frames are other automotive part manufacturing that use sheet metal fabrication.

Farming

The farming industry needs sheet metals for producing various harvesting tools. Livestock management also uses sheet metals for their equipment, such as milking and feeding machines. Want to make a greenhouse? You will also need to rely on sheet metal fabrication for that.

Military

Specific sheet metals become the primary materials for creating military vehicles. The military industry will need to use more durable sheet metals for their armored trucks. Military planes also use sheet metal fabrication for their components, such as wings and cockpit areas. The same also goes for military tanks.

Oil and Gas

The oil and gas industry always needs durable custom sheet metal components capable of withstanding various environmental conditions. Precision sheet metals are in high demand in the oil and gas industry, with different requirements for each territorial need. Sheet metals are also usable for creating structural objects for the oil and gas industry.

Medical

In the medical industry, precision is everything. You will need different sheet metals to create surgical and medical tools. Scalpels and clamps are commonplace surgical tools that need sheet metal fabrication to produce. Hospital beds and other medical devices equipment also need sheet metal structures to make.

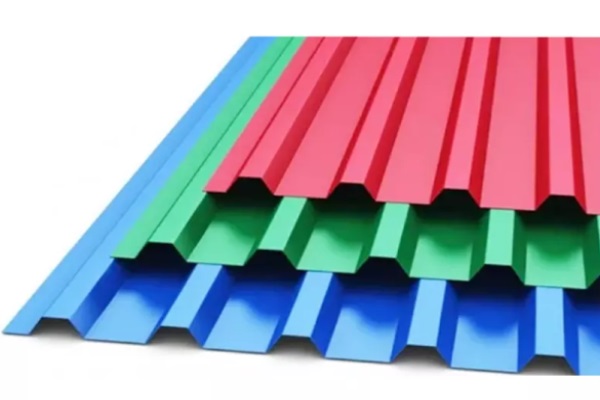

Construction

The basic structures of any construction or building often use sheet metals in their production. Rooftops and building partitions also use sheet metal fabrication to make. It uses the cladding technique to put them in place around the building. You can also use sheet metals for regular and emergency staircases in various buildings.

Telecommunications

The telecom industry uses sheet metal components intensively, such as for cellular towers. Telecommunication equipment, racks, and panels also use sheet metals to function. Many tools for networking and cellular devices use both small-scale and large-scale sheet metal fabrication to produce.

Electronics

Electronic devices and components use thin metal sheets to ensure the best features for them. Sheet metals in the electronics industry have a wide range of applications. PC enclosures, circuit boards, and connectors use sheet metals at different specifications. Electronics will not work well without the use of sheet metal fabrication.

Food Services

Some food containers use sheet metals to keep the foods safe to consume for a long time. Canned foods also use sheet metal fabrication to produce the cans, allowing you to store the foods safely. The food industry also uses metal sheets for food storage and cooling equipment.

Prototyping with Sheet Metal Fabrication

Sheet metal prototyping is commonplace to test the sheet metal components before mass producing them. It is an essential link in the entire sheet metal fabrication process. You must go through various stages of rapid prototyping before the final production. Here are some stages of sheet metal prototyping that are applicable in any industry:

Design of sheet metal fabrication

The design stage in sheet metal prototyping allows you to play with different ideas and put them into your production plan. You will use the 3D design software to create sheet metal prototype variations for your manufacturing project. You can create as many designs as possible at this stage.

Sheet Metal Fabrication

Next, you can pick the design you want to produce as a prototype. Then, you can start the sheet metal fabrication process. The sheet metal fabrication will include forming, folding, welding, and other related techniques. This process follows the design blueprint to the letter to produce the required prototype.

Feature Testing

Completing the prototype fabrication will not be the end of your production phase. You will need to test each feature of the sheet metal prototype one by one. You will also need to check the integrity of the components for the assembly process. This phase will help you find any issues with the sheet metal components.

Revision

Next comes the revision process for the sheet metal prototype. You will need to gather the data and feedback from the testers regarding the prototype you make. Then, fix any issues by creating a revised design for the prototype and rapid manufacturing. You will need to do this repeatedly until you resolve all problems.

Sheet Meta Fabrication Production

You can go with the final production phase after resolving all problems with your prototype revision. The end product of the sheet metal components will be usable in real-world applications in your respective industry.

Conclusion

Sheet metal fabrication has plenty of applications in different industries. You can make different sheet metal components with different industrial specifications. Varying requirements will be applicable for different usage scenarios based on various aspects. These aspects include environmental conditions, terrains, usage periods, health and safety, and more.

Sheet Metal Fabrication with Team Rapid Tooling

Team Rapid Tooling provides customizable sheet metal fabrication services to fulfill every requirement you have for your industry. You can determine your sheet metal specifications, and we can work to complete it in a few weeks. We also offer other manufacturing-related services at https://www.teamrapidtooling.com/. and contact us.