Blow molding and injection molding are the two common molding methods used in today’s manufacturing industry. Blow molding or injection molding, which one is right for my projects? In this guide, you will learn about the difference between them.

Table of Contents

What is Blow Molding?

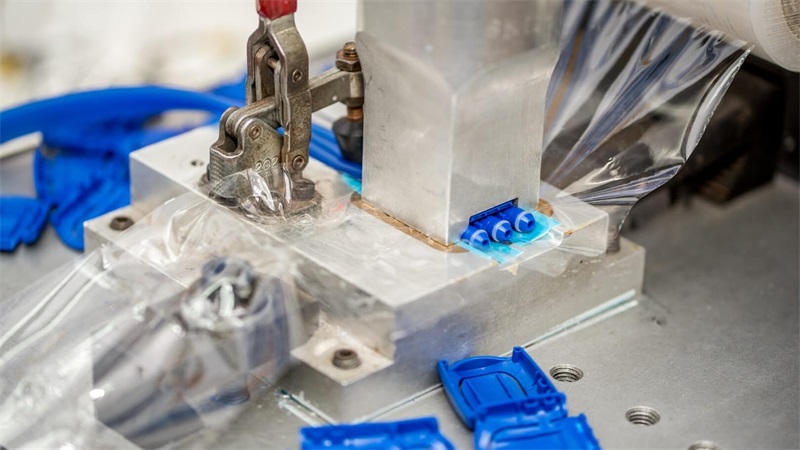

Blow molding is the manufacturing process that involves blowing air inside the molten plastic tube to create certain hollow shapes. Manufacturers often use this process to create plastic bottles and other containers. There are three types of blow molding in manufacturing: extrusion, injection, and injection stretch blow molding.

●Extrusion blow molding.

In this process, the melted plastic material will extrude into a container called a parison or hollow tube. The parison will enter the metal mold and get blown to create a hollow shape according to the product design. Then, it will need to cool down before you can eject the product from the extrusion blow molding equipment.

●Injection blow molding.

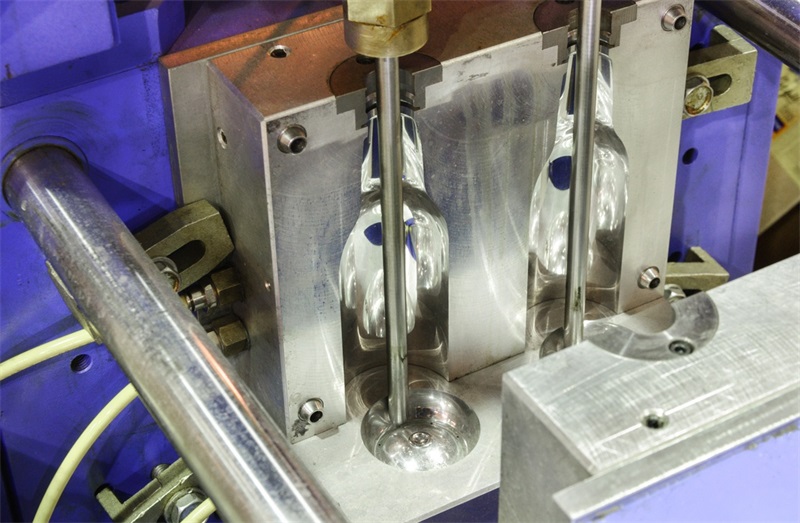

This is the blow molding method used to create large-quantity hollow glasses or plastic objects. Often, manufacturers use this process to create small bottles in the medical industry. It works like the extrusion blow molding method, with the only difference being that it uses injection molding at the start of the process.

●Injection stretch blow molding.

Injection stretch blow molding, as the name suggests, is the blow molding method that includes injection, reheating, and stretch blow phases in its process. First, you will need to mold the plastic material in the preform shape (or melted and heated form). Then, by using the reheat stretch blow equipment, you can create the hollow part inside the plastic material by stretch-blowing it and producing the object you want to get, such as bottles and containers.

What is Injection Molding?

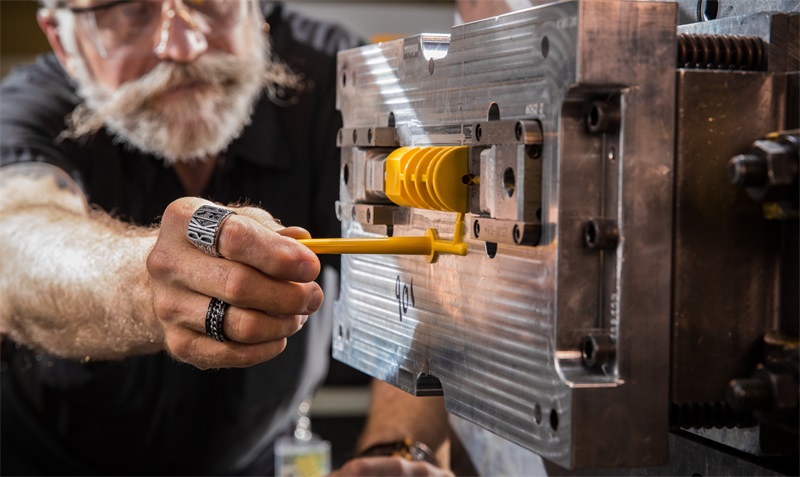

Injection molding can be a rapid manufacturing process that allows you to produce prototypes, parts, and components in large quantities. It works by melting the plastic material and pouring it into the mold cavity so that the melted plastic will follow the shape of the mold. Then, you will need to cool the plastic material down before you can eject and use it further in your production process.

The most common materials for plastic injection molding service are thermoplastics and thermosetting polymers. However, there are other materials you can use, such as glasses, metals, elastomers, and confections.

Blow Molding Advantages

Blow molding has its advantages. However, this method will only limit you to creating a hollow shape on melted thermoplastic materials. This is the primary method manufacturers will use to create plastic bottles and containers. You can’t use blow molding for any other purpose other than to create hollow shapes within thermoplastic materials.

●Creating hollow shapes for various objects.

Blow molding is the primary molding process you can use to create hollow shapes for various objects. No matter how small or how big the object is, you can create a hollow shape in it by using the blow molding process.

●Several blow molding methods to use.

There are various blow molding methods you can use, such as extrusion, injection, and injection stretch blow molding, which you can use for different purposes. For instance, you can use the injection blow molding process to produce small medicinal bottles in large quantities.

●Fast production cycles.

The entire process of blow molding is quite fast to complete, from the melting process, extrusion process, blowing process, and cooling process, to the ejection process. So, you can produce high quantities of plastic bottles in a short amount of time with the blow molding method.

●Cheap tooling costs.

The tooling costs for the blow molding method are also cheaper to make, along with the costs for the dies. With an easier way to create the tools for the blow molding method, you can prepare the production phase much faster, which helps with increasing your production efficiency for the long term.

●Complex design requirements.

Some bottles or containers might have unique or intricate designs. The good news is that blow molding can handle some complicated designs for your plastic bottles or containers. You can combine blow molding with injection molding to produce the complex shapes you want to create for your product.

Injection Molding Advantages

Injection molding is a common molding method used in a wide range of industries. Manufacturers often use this method to create plastic parts, insert molding prototypes, or components in fast production cycles and large quantities.

●Reliability and repeatability.

The injection molding process is reliable, which means you can rely on its result again and again, no matter how often you do it. It can produce similar results for your prototypes, overmolding parts, and components, which also means that you can repeat the process for large volumes of production.

●Compatible with complex geometry designs.

Injection molding is also compatible with complex geometry designs, allowing you to create prototypes, parts, and components with complex shapes or designs. You just need to create suitable molds for your complex shape designs, and you are ready to go.

●A wide range of materials and colors.

You can use a wide range of materials and colors with injection molding. So, it’s not limited to just plastic materials. You can also use other materials, such as metals and glasses, in your injection molding process. You can also use different colors for the prototypes, parts, and components you create with this process.

●High efficiency with less material waste.

Injection molding doesn’t generate much material waste. In fact, you can reuse the material waste generated by the injection molding process, which will bring higher efficiency to your production.

Which One is Better – Blow Molding or Injection Molding?

Both these 2 moldings have their own purposes, so you can’t say which one is better. In fact, these two methods can complement each other in the manufacturing process. You can use injection molding at the start of the blow molding process to create complex shape designs for your plastic bottles or containers.

So, these two methods can go hand in hand in the manufacturing process, helping the manufacturers to speed up their overall production cycles while improving the quality of their products.

Conclusion

Blow molding and injection molding have their differences, but these methods can also complement each other. You can use injection molding to create the basic shell for the container product, and then use blow molding to create a hollow shape in it.

These two molding methods are an important part of today’s manufacturing industry. TEAM Rapid offers a series of rapid manufacturing methods such as rapid prototyping services, CNC turning, 3d printing services online, injection molding, etc for your needs. Contact us today to learn more now!