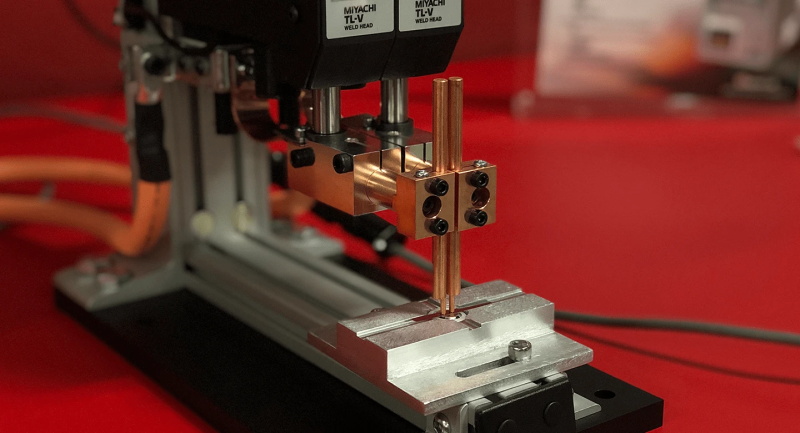

Spot welding, also called spot resistance welding, is a welding process you can use to weld different sheet metal materials by electric currents. This welding process uses the heat resistance of the sheet metal materials against the electric currents from the spot welder to generate heat on the surface of the metals. This way, you can weld the sheet metal parts together. The spot welder equipment uses two copper alloy electrodes to perform this process. In this guide, you can learn about this welding, including its process, applications, and primary advantages.

Table of Contents

What Makes Spot Welding Unique?

There are various types of welding methods you can use in the manufacturing process. Spot welding is one of them. However, the welding has its own uniqueness when compared to the other welding methods you can use in manufacturing. This uniqueness often becomes the reason manufacturers prefer to use it in their production and rapid manufacturing process. Here are some important points that make this welding unique:

●Heat resistance technology.

Spot welding uses heat resistance technology to join two different sheet metals together. It works by creating electric currents on the welding electrodes, which trigger the heat resistance on the metal surface. It is what makes this process different from other welding processes.

●Safety factor.

This welding is also safer than the other welding processes, as it uses electric currents only at certain spots on the sheet metal surface.

●Ease of use.

Different from the process such as CNC turning and insert molding, Anyone can use the spot welder equipment, so manufacturers don’t need to hire specialized professionals to get the job done

●Spot welding has a Faster production cycle.

The welding process is fast, and it is often faster than the other welding methods. This is the reason manufacturers use this welding in rapid prototyping service and to speed up their production cycles.

Spot Welding Process Explanation

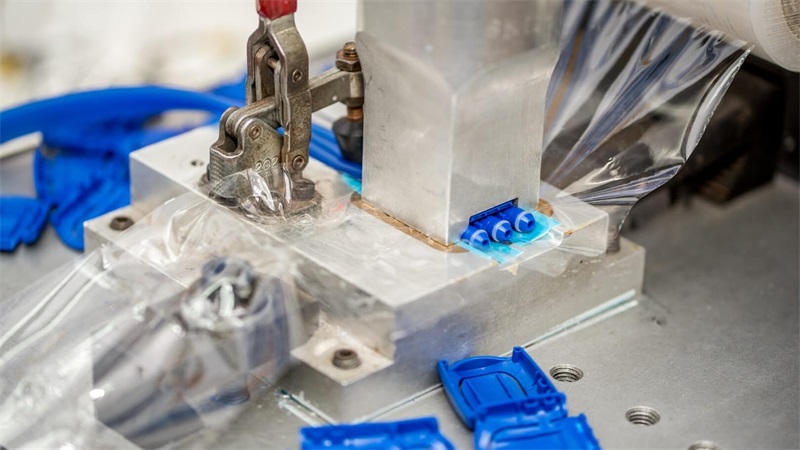

It is a simple welding process. For you to use this process in manufacturing, you will need to prepare the spot welder equipment. The spot welder equipment has the copper alloy electrodes you will use as the primary welding tool. You will need to create the electric currents around the electrodes, so you can use the electric currents to weld the sheet metal materials at certain spots. After charging the electrodes with electric currents, you will need to point to the specific spot on the sheet material surface you would like to weld. The heat resistance of the sheet metal materials on that spot will create the heat necessary for the welding process. Thus, the sheet materials will get fastened by the heat resistance, and you can continue the process by welding different spots on the sheet metal materials.

Spot Welding Applications

It is quite a common welding method used in various manufacturing industries. It has a wide range of applications, meaning that you can use spot welding for various types of manufacturing processes. For instance, spot welding has common applications in the automotive industry, and in die casting for industrial component. Here are some applications of this welding in today’s manufacturing processes

●Sheet metal fastening.

It is a common method used by manufacturers for fastening various sheet metal materials together. With this method, you can fasten the sheet metals much faster than regular welding, and the result you will get will also be better. You can rely on this welding if you want to join different sheet metals for the best mechanical strength

●Boxes and cases.

Another use of this welding is in the fastening of boxes and cases, such as the ones made from aluminum and other metals. It will be easier for you to join the boxes and cases together using this welding instead of the regular welding methods.

●Automotive and aerospace.

It can provide a much more reliable fastening method for various automotive and aerospace parts. Thus, you can make the metal parts from the automotive and aerospace industries much stronger when you use spot welding to join them together

●Consumer electronics.

Not only in aerospace and automotive industries, but spot welding is also useful to fasten various sheet metals in consumer electronics. You can get much cleaner results when you use the process to join the metals in various consumer electronic products.

●Rapid metal prototyping.

Because of how fast it is to apply to this welding, you can use this method in sheet metal prototype and other rapid metal prototyping. Manufacturers can increase their production output by using this welding instead of the more time-consuming regular welding methods.

Primary Advantages of Spot Welding

In manufacturing, this welding has become the preferred method for manufacturers to weld certain metal sheet materials. It is easy to do, and it also doesn’t cost a lot of money for manufacturers to perform this process. Thus, the welding can give plenty of advantages to manufacturers to increase their production efficiency. Here are some primary advantages of spot welding in manufacturing:

●Affordable manufacturing costs by spot welding.

First, spot welding is a simple welding process anyone can do, meaning that you don’t need to hire specialized professionals just to perform this process. Also, it doesn’t require you to add various extra materials in the welding process, making it an affordable tool in manufacturing.

●Great for lightweight metal sheets.

It is suitable for lightweight metal sheets, such as aluminum and copper, while causing no burns on the material surface. With the other traditional welding or fastening processes, you might damage the materials when trying to join them. However, with this welding, you can do it with no problem.

●Great workmanship.

The fastening process done using spot welding will create uniform joints, which look good on the material surface. You don’t need to worry about making untidy joints on the material surface when you use spot welding.

●Compatibility with various metal materials.

You can use this welding for various metal sheet materials, whereas you can’t do the same using regular welding methods. This compatibility with various metal materials is something that makes spot welding the preferable welding method for many manufacturers. It can also increase production efficiency and speed up production cycles.

Conclusion

Spot welding is a simple welding process that uses heat resistance technology, which allows manufacturers to apply the welding process on various sheet metal materials. It has a wide range of applications, and it allows manufacturers to speed up their production cycles.

With the various advantages of spot welding, manufacturers can also work with much more efficiency in their production process, allowing them to get better production results while minimizing the costs of production. Are you looking for this welding, plastic injection molding service as well as other manufacturing services? Contact us to request a free quote now!