Clear plastic moulding, a prevalent method in manufacturing, holds significant environmental significance. In response to the urgent need for sustainability, embarking on a journey to discover eco-friendly solutions within this industry is imperative. This article explores sustainable practices for clear plastic moulding, emphasizing their crucial role in preserving our environment.

Table of Contents

The Current State of Clear Plastic Moulding

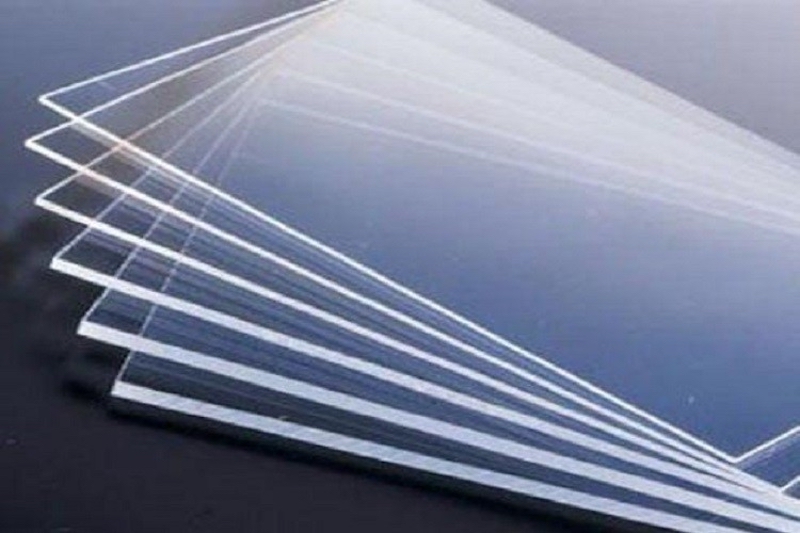

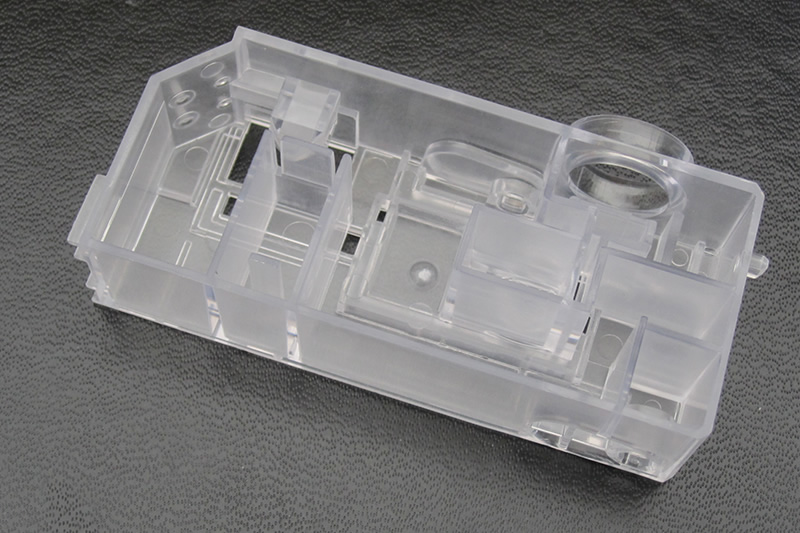

Clear plastic moulding

A fundamental aspect of modern rapid manufacturing, employs diverse techniques, each imprinting a distinct environmental mark. Injection molding, a prevalent method, injects molten plastic into molds, shaping intricate designs efficiently. Yet, this process often hinges on non-renewable resources, contributing to environmental apprehensions.

Thermoforming

Another widely adopted method, heats plastic sheets to a pliable state before plastic molding them into desired forms. While allowing for design versatility, the energy-intensive heating phase raises questions about overall sustainability.

Blow molding

Employed for crafting hollow plastic items, entails inflating heated plastic into a mold / rapid tooling. Despite its efficiency in mass production, the energy demands during heating and cooling pose challenges for true eco-friendliness.

The environmental impact extends beyond resource consumption. Disposing of waste generated during molding poses a significant concern, with non-biodegradable plastics risking pollution and ecological imbalance if not managed responsibly.

In response, innovative approaches are emerging. Companies increasingly adopt recycled and biodegradable plastics, aiming to alleviate the environmental toll of traditional molding. Advances in energy-efficient technologies reshape the landscape, minimizing the carbon footprint in clear plastic moulding.

Fostering sustainability requires collaborative efforts. Industry stakeholders must prioritize research and development, exploring alternative materials and refining processes for eco-friendly objectives. Embracing these changes positions the clear plastic moulding sector as a trailblazer for a more sustainable and environmentally conscious future.

The Importance of Sustainability in Plastic Moulding

Sustainability stands as a critical linchpin in the realm of plastic molding, underscoring its pivotal role in ensuring the industry’s enduring viability. In the current climate of heightened environmental awareness, the imperative to integrate eco-friendly practices into plastic molding processes is indisputable. Disregarding sustainability not only imperils the environment but also exposes the industry to profound risks.

In an era where climate change looms large, the adoption of sustainable practices in plastic injection molding becomes an ethical obligation that cannot be understated. Conventional plastic production methods, reliant on non-renewable resources and energy-intensive processes, contribute significantly to carbon emissions and environmental degradation. As consumers increasingly prioritize environmentally conscious products, companies failing to align with sustainable practices risk alienating their customer base and losing market share.

Beyond consumer preferences, regulatory bodies are progressively tightening environmental standards. Disregarding sustainability in plastic molding may result in non-compliance with rigorous regulations, exposing companies to legal ramifications and financial penalties. The industry’s trajectory hinges on its capacity to adapt and adhere to evolving environmental benchmarks, making sustainability not just an ethical mandate but a strategic imperative.

Furthermore, the repercussions of environmental neglect extend beyond corporate concerns to impact ecosystems and human health. Unsustainable plastic molding practices contribute to the pollution of air, water, and soil, precipitating a global crisis. Plastic waste accumulation in landfills and oceans jeopardizes biodiversity, marine life, and human populations alike.

In light of these challenges, embracing sustainability emerges not as a discretionary measure but as an intrinsic survival strategy for the plastic molding industry. The potential ramifications of disregarding this imperative encompass not only environmental concerns but also economic and reputational risks. Companies that proactively integrate sustainable practices into their operations or even low volume manufacturing services contribute not only to a healthier planet but also position themselves as vanguards in an industry navigating the intricate intersection of innovation and environmental responsibility.

Eco-Friendly Solutions for Clear Plastic Moulding

Eco-friendly solutions are gaining prominence in the clear plastic molding industry as a strategic response to mitigate its environmental impact. The adoption of these solutions is crucial for the industry’s sustainability. Now, let us explore essential eco-friendly measures that are reshaping the landscape:

Recycling and Waste Reduction

Lean manufacturing programs are being implemented to curtail waste generation and recycle excess plastic from the molding process. When executed effectively, this approach can eradicate plastic waste generation.

Energy from Waste

Technological advancements in mold technology and plant efficiency have substantially reduced power consumption. Energy-from-waste technology not only slashes molding costs but also contributes to making facilities landfill-free, marking a notable leap in environmental responsibility.

Use of Biopolymer Plastic Material

Companies are incorporating eco-friendly solutions like biopolymer plastic material into their products. This dual-pronged approach delivers an environmentally conscious product while concurrently reducing costs for customers.

These initiatives represent a pivotal stride in rendering clear plastic moulding more sustainable. Yet, it is imperative to acknowledge that continuous research and development remain imperative for refining existing methods and uncovering innovative solutions. The journey toward a greener, more sustainable plastic molding industry is an ongoing one, underscoring the industry’s commitment to evolving practices in harmony with environmental responsibility.

The Future of Sustainable Clear Plastic Moulding

The future of sustainable clear plastic molding charts a promising course, marked by a profound shift towards environmentally conscious practices. Adopting biodegradable resins and intensifying recycling efforts hold substantial potential to significantly reduce the industry’s ecological footprint. This strategic evolution not only aligns with heightened consumer environmental awareness but also positions manufacturers to meet stringent regulatory standards, ensuring enduring relevance and sustainability.

As companies increasingly embrace lean manufacturing and leverage energy-from-waste technologies, a notable surge in operational efficiency is anticipated, heralding a paradigm shift in energy consumption and waste management. The industry’s trajectory towards incorporating biopolymer plastic materials in products signifies a dual advantage of environmental conscientiousness and economic viability.

This commitment to sustainability not only augurs well for the industry’s public image but also carries the potential for economic advantages. Companies at the forefront of these initiatives are likely to gain a competitive edge by appealing to environmentally conscious consumers, thereby enhancing their market standing.

Conclusion

The imperative shift towards sustainable practices in clear plastic moulding is undeniable. From the adoption of biodegradable resins to robust recycling initiatives, the industry is poised for a transformative evolution. This commitment to eco-friendly solutions not only meets consumer expectations but also guarantees long-term viability, reaffirming the industry’s dedication to environmental responsibility.

Besides from injection molding, TEAM Rapid also offers rapid prototyping, CNC machining, and die casting for your project needs. Contact us today to request a free quote now!