Clear plastic molding, a pivotal force in shaping automotive interior design, seamlessly marries aesthetics with functionality. Its transparency and versatility usher in unique design possibilities, making it an integral aspect of modern vehicles. This exploration delves into its applications, benefits, and the anticipated future trends within the dynamic realm of the automotive industry.

Table of Contents

- 1 Understanding Clear Plastic Molding Materials for Automotive Interior Design

- 2 Application of Clear Plastic Molding in Automotive Interior Design

- 3 Advantages of Using Clear Plastic Molding in Automotive Interior Design

- 4 Future Trends in Clear Plastic Molding for Automotive Interior Design

- 5 Conclusion

Understanding Clear Plastic Molding Materials for Automotive Interior Design

Clear plastic molding stands as a pivotal manufacturing process employed to craft components with a transparent or clear finish. This intricate technique involves injecting molten plastic into a mold, a method that, when cooled and ejected, yields a clear plastic part. The transparency of the final product hinges on both the type of plastic selected and the intricacies of the manufacturing process.

Polycarbonate (PC)

Recognized for its robustness and longevity, frequently finds application in automotive contexts due to its resilience against impacts and the resultant clear finish.

Polyethylene Terephthalate (PET),

A clear, sturdy, and lightweight plastic, enjoys widespread use, particularly in packaging applications.

Acrylic (PMMA)

Commonly known as Plexiglas, mirrors the clarity of glass while boasting enhanced durability and reduced weight. Within automotive interiors, it often graces elements like instrument panels.

Polyvinyl Chloride (PVC)

Typically opaque or white, can be rendered clear and exhibits versatility across various applications.

Polystyrene (PS)

A firm and transparent plastic, finds its niche in applications requiring visibility, such as car light covers.

Each of these plastics brings forth distinct advantages, rendering them suitable for diverse applications within the realm of automotive interior design. The careful selection of the appropriate clear plastic ensures optimal performance and aesthetics, contributing to the seamless fusion of form and function.

Application of Clear Plastic Molding in Automotive Interior Design

Clear plastic injection molding has ushered in a new era in automotive interior design, seamlessly blending aesthetics, durability, and versatility. This transformative technique empowers designers to craft intricate shapes and designs, pushing the boundaries of what can be achieved with alternative materials.

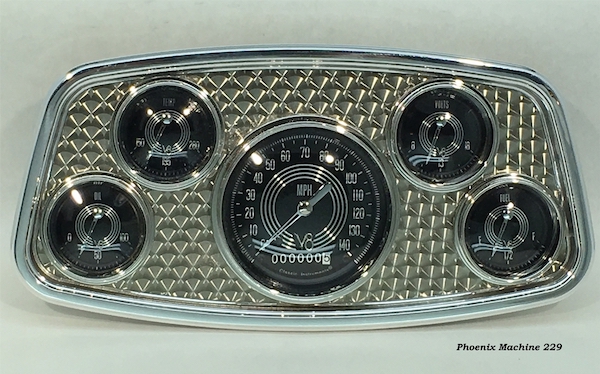

A prime example of clear plastic molding’s influence on automotive interiors lies in the crafting of instrument panels. These panels, often fashioned from clear acrylic or polycarbonate, serve as homes for a vehicle’s gauges and indicators. The transparent nature not only facilitates easy reading of displayed information but also elevates the vehicle’s overall aesthetic appeal.

Control buttons and switches, vital components overmolding demanding durability and clear labeling, also benefit from clear plastic molding. This method enables the integration of symbols and labels directly into the button or switch, ensuring resilience against wear and tear for long-lasting functionality.

Clear plastic molding finds application in the production of lighting components. Tail lights, indicator lights, and interior ambient lighting all embrace clear plastic elements, effectively diffusing light and enhancing the vehicle’s safety features.

Clear plastic molding plays a crucial role in shaping storage compartments and cup holders. The transparent plastic not only imparts a sleek and modern aesthetic but also facilitates easy cleaning and maintenance, adding practicality to the design.

Advantages of Using Clear Plastic Molding in Automotive Interior Design

Clear plastic molding stands as a transformative force in automotive interior design. Delivering a host of advantages that profoundly enhance the aesthetics, safety, and functionality of the car interior.

The foremost benefit lies in the realm of aesthetics, where clear plastic molding facilitates the creation of designs characterized by sleek modernity. The transparent nature of the material adds an element of sophistication. Permitting the integration of intricate shapes and textures that may pose challenges with alternative materials.

Safety

In the pursuit of safety, clear plastic molding plays a pivotal role by improving visibility in critical components. Instrument panels and control buttons, crafted through this method. Offering unobstructed views, ensuring drivers can access information without compromising attention to the road.

Durability

Durability is a paramount consideration, and clear plastic molding excels in this domain. Components subject to frequent interaction, such as control buttons, benefit from the resilience of clear plastic, maintaining both clarity and functionality over extended periods.

The versatility of design stands out as a notable advantage. Clear plastic molding allows for the creation of complex shapes and forms, empowering designers to innovate and push the boundaries of both aesthetics and functionality.

The transparency inherent in clear plastic enhances functionality within the car interior. Components like lighting elements benefit from efficient light diffusion, contributing to the overall atmosphere and, crucially, safety by improving visibility inside and outside the vehicle.

Weight Reduction

Weight reduction emerges as a less apparent yet impactful advantage. Clear plastic, being lighter than certain alternative materials, contributes to overall weight savings in the vehicle, potentially enhancing fuel efficiency and performance.

Ease of maintenance is a practical boon, particularly in components like storage compartments and cup holders. The smooth surface of clear plastic is effortlessly cleaned, ensuring these frequently used elements remain pristine with minimal effort.

Cost-effectiveness in Automotive Interior Design

Cost-effectiveness completes the list of advantages. Clear plastic molding offers an efficient and economical rapid manufacturing process, leading to overall cost savings in the production of automotive interior components.

Future Trends in Clear Plastic Molding for Automotive Interior Design

The trajectory of transparent plastic molding in automotive interior design points to a dynamic future. It features innovative trends that will reshape the aesthetic and functional dimensions of automotive interiors.

Smart Surfaces

A forthcoming trend envisions the incorporation of smart surfaces through clear plastic molding. These surfaces are anticipated to host touch-sensitive controls and interactive displays, transforming conventional components like dashboards and control panels into dynamic and user-friendly interfaces.

Sustainable Materials

The growing emphasis on sustainability is expected to drive the adoption of environmentally conscious materials in clear plastic molding. The industry is likely to explore and implement recyclable and biodegradable plastics, aligning automotive interiors with broader environmental considerations.

Advanced Lighting Integration

Another prominent trend on the horizon involves the seamless integration of advanced lighting technologies within clear plastic components. Ambient lighting, illuminated controls, and programmable LED accents are poised to enhance both the visual appeal and functional aspects of automotive interiors.

3D Printing Applications in Automotive Interior Design

The integration of 3D printing into clear plastic molding is gaining momentum as an innovative approach. This method allows for intricate and customizable designs, ushering in a level of personalization in automotive interiors previously considered unattainable.

Haptic Feedback

Clear plastic molding is anticipated to incorporate haptic feedback technology, adding a tactile dimension to touch-sensitive surfaces. This innovation aims to enrich the user experience by providing physical feedback, simulating the tactile feel of traditional buttons on otherwise flat surfaces.

Integration of Augmented Reality (AR)

Clear plastic components are poised to serve as mediums for augmented reality displays shortly. For instance, windshields could incorporate AR elements, offering real-time information and elevating the driving experience through clear plastic molding applications.

Conclusion

Clear plastic molding stands as a transformative influence in automotive interior design, seamlessly harmonizing aesthetics, safety, and functionality. Innovations such as smart surfaces and sustainable materials further underscore its significance. As trends progress, clear plastic molding is poised to redefine the future of automotive interiors, promising a dynamic and sophisticated driving experience.

TEAM Rapid offers rapid prototyping, injection molding, CNC machining, and die casting to meet your projects needs. Contact our team today to request a free quote now!