Rapid prototyping is the fast method to fabricate a physical part, model or assembly by CAD design. The parts, models or assembly is usually made by additive manufacturing which is well known as 3D printing. There are two types of prototypes: high-fidelity prototypes and low fidelity prototypes. There are several rapid prototyping technologies. At Team Rapid, we will offer the best rapid prototyping technique for your products. Here, we will list the different types of rapid prototyping in 2024. We will also include the advantages and disadvantages of each type of rapid prototyping.

The four main type rapid prototyping are selective laser sintering (SLS), selective laser melting (SLM), stereo lithography (SLA), and fused deposition modeling (FDM). Each type has its own process and advantages.

Table of Contents

1, Selective Laser Sintering (SLS)

SLS can be used to create both metal and plastic prototypes. SLS uses a powder bed to build prototype layer by layer with a laser to heat and sinter the powdered material. SLS is a process that powdered/granular plastic or metal is joined by pressure and /or heat. The main advantage of SLS is it does not need supports as SLA does. With SLS, there is no special tools or dies needed to create the parts which will balance the cost of producing SLS parts. SLS part can be created within one days, so it is a perfect type of rapid prototyping to produce viable prototypes and parts with complex designs and single pieces. The strength of SLS parts is not as good as SLA parts. And the surface of SLS parts is rough and may need additional work to make it smooth.

2, Selective Laser Melting (SLM)

SLM process is referred to as powder bed fusion. It is ideal to create parts with high strength and complex. SLM parts are widely used in many different industries like aerospace, automotive, defense, and medical etc. SLM process uses a fine metal powder which is melted layer by layer to make parts using a high power laser or electron beam. There are many materials available in SLM which include titanium, aluminum, stainless steel and cobalt chrome alloys. SLM is one of the popular types of rapid prototyping as complex designs and internal aspects which reduce weight and increase strength are fast and efficiently achievable.

3, Stereo Lithography (SLA)

SLA is the fast and inexpensive type of rapid prototyping. It was the first successful method of 3D printing. SLA is a process that a bath of photosensitive liquid is used which is solidified layer by layer by UV light. SLA requires 3D CAD software to build the parts’ geometry and supports need to add structure to the parts. SLA can create extreme detail and a finished surface. SLA parts can be made quickly and sometime even in a less than one day. The main disadvantage of SLA is it has size limitation and the process is expensive.

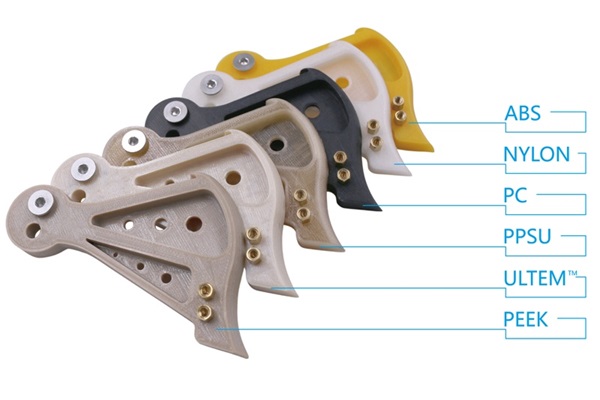

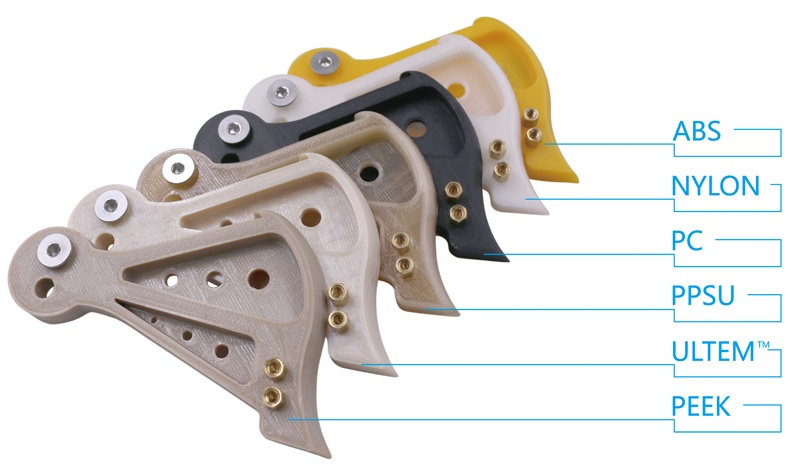

4, Fused Deposition Modeling (FDM)

FDM is an inexpensive and easy to use process. A spool of thermoplastic filament is used that is melted in a pressure nozzle housing before the resulting liquid plastic is deposited layer by layer according to a computer program. FDM is quick and cheap. FDM is an ideal type of rapid prototyping for product development.

Which Types of Rapid Prototyping is the right for your parts?

Choosing the right type of rapid prototyping depends on the parts design. It is very important to understand the advantage and disadvantages of each type of rapid prototyping when choosing the right type of rapid prototyping.

one to choose. SLA is accurate but it has limitation in available material, SLA needs supports and need to be cured after production. SLS does not need post curing. SLS has a wide range of material choices. SLS needs finishing and changing from different materials. FDM has no need for curing, range of materials. It is easier changeover. FDM takes longer time to make larger parts.

If you understand the process, advantage and disadvantages of each type of rapid prototyping, choosing the right type of rapid prototyping is easy. Your budget, material, size, and time requirement are the main factors to considering which type of rapid prototyping is best for your projects. Contact us today to learn more now!