There are various types of plastic materials used in manufacturing processes nowadays. Manufacturers use these plastic materials to create various sheet metalwork parts, components, rapid prototypes, and completed products in various industries. Thermosets and thermoplastics are manufacturers’manufacturers’ most common plastic materials in their production cycles.

What are thermosets and thermoplastics, and what are their differences? This guide will teach you the definitions and differences between thermosets and thermoplastics.

Table of Contents

What are Thermosets?

Thermosets, often called thermosetting polymers, are plastic materials with rigid and durable characteristics, which you can shape once. You can’t reshape or remold the thermoset plastics after it takes the initial form. This is one of the most common materials you can use to create sturdy plastic molded products in various industries, including home appliances, automotive, overmolding electronics, and more.

Creating products from thermosets follows the same process as when using any other plastic materials, which is done using heat treatment. However, you can only apply heat to the thermoset plastic materials once, and after that, you can’t change the form or shape of the completed products with the further heat treatment process.

What are Thermoplastics?

Thermoplastics are another type of plastic material with the opposite characteristics of thermosets. Thermoplastics have flexible and elastic properties, unlike thermosets, which are rigid and durable. So this is the plastic material suitable for creating various flexible products, such as cables, electric insulators, clear plastic wheels, and many others.

With thermoplastics, you can heat the primary material to get the form or shape you want, and the end product will have flexible and elastic properties. Thermoplastics also have a low melting point, so you can melt the molded thermoplastic products and return them to their previous liquid state. You can also reshape or recycle the materials later.

The Differences between Thermosets and Thermoplastics

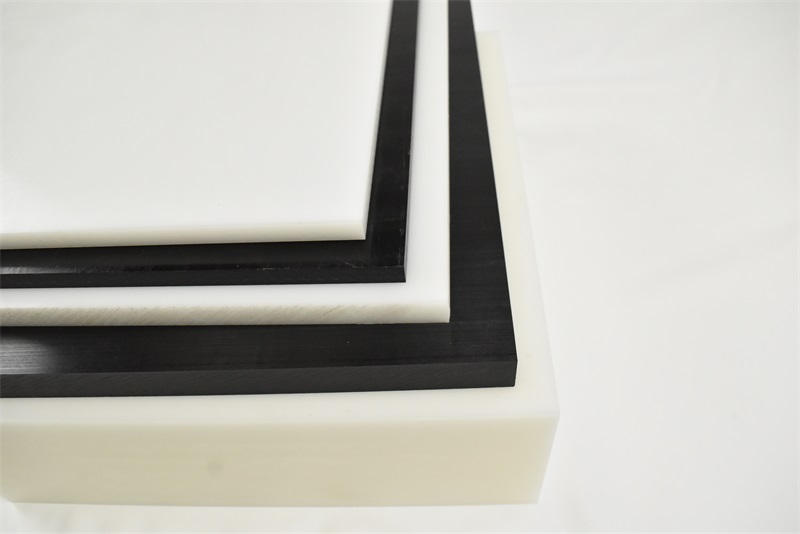

Thermosets and thermoplastics have opposite characteristics, despite being in the same plastic material category. You will need to use thermoset plastic materials to build hard shells and insert molding housings, giving you tough and durable end products. However, you will need to use thermoplastic materials to create elastic and rubbery hardware parts and components. Here are the differences between thermosets and thermoplastics:

●Malleability and recyclability.

Thermosets are rigid plastic materials that are not malleable and recyclable when exposed to high temperatures. Meanwhile, thermoplastics are elastic materials that are malleable and recyclable when exposed to high temperatures.

●Basic characteristics of Thermosets and Thermoplastics.

Thermosets are durable and sturdy, so that you can use them as the basic materials for shells, housings, or casings. Meanwhile, thermoplastics are elastic materials that have poor durability compared to thermosets.

●Melting point of thermosets and Thermoplastics.

Thermosets have a very high melting point, as it is resistant to high temperatures after the initial forming. In contrast, thermoplastics have a low melting point, which is susceptible to melting when exposed to high temperatures.

●Weight.

Thermoset materials are heavier than thermoplastic materials because of their sturdiness and durability. Meanwhile, thermoplastic materials have a lightweight characteristic because of their elastic properties.

●Resistance.

Thermosets are resistant to corrosion and water damage, whereas thermoplastic materials have excellent impact resistance, detergent resistance, and chemical resistance.

Thermoset Pros and Cons

Pros

●Tough and durable material with excellent mechanical properties.

●It has high resistance to high temperatures, with excellent dimensional stability.

●You can apply various high-quality aesthetics as the surface finishes for the thermoset materials.

●It has excellent resistance to water damage and corrosion.

●Lower tooling and rapid manufacturing costs; you can also produce the end products faster using thermoset materials.

Cons

●You cannot reshape, reheat, recycle or remodel thermosets once it reaches their initial forming stage.

●It has a high material rigidity, which can cause cracks or damage when you use it for intensive physical activities.

●Thermosets also have bad thermal conductivity, which is why you should know you shouldn’t use these materials for heat dissipation.

●It will take quite a lot of time and effort to create a surface finish for this plastic material.

Thermoplastic Pros and Cons

Pros

●Thermoplastics are easy to recycle, remold, and reshaped.

●It is a flexible material that you can use for applications that require high flexibility, such as cables and electrical insulators.

●It has a high level of impact resistance, along with excellent detergent and chemical resistance.

●This material is also resistant to corrosion and has excellent slip enhancement.

●The thermoplastic materials are lightweight and flexible, and you can use them in high-volume injection molding services production.

Cons

●It will have an unstable form when you heat this material.

●This material will have much more expensive production and tooling costs than thermosets.

●Thermoplastics are also vulnerable to cracking or creep when exposed to too much stress and material stretches.

●It also has a low melting point, meaning it won’t withstand high temperatures for too long.

Thermosets and Thermoplastics, Which one is Suitable for your Projects

Both thermosets and thermoplastics have their uses, so they complement each other. Depending on the industrial applications you are working on, you might need to use both materials to create various parts and components for your product assembly process.

For instance, in the automotive industry, thermosets and thermoplastics are useful for creating various vehicle parts. You might use thermoset materials to create durable dashboard shells, whereas you might need to use thermoplastic materials to create the wheels for the vehicle.

It’sIt’s also the same in other industrial applications, such as electronic products. You will need to use thermoset materials to create the housing or casing for the electronic products, and you will need to use thermoplastic materials to create the cables and electric insulator components.

Conclusion of Thermosets and thermoplastics

Both thermosets and thermoplastics are important plastic materials used in various manufacturing processes to produce various parts, components, and prototypes in various industries. Thermosets have rigid and durable characteristics, whereas thermoplastics have malleable characteristics.

You can use both thermoset and thermoplastic materials in high-volume production processes. These materials offer much more affordable tooling and production costs when compared to other molding materials.

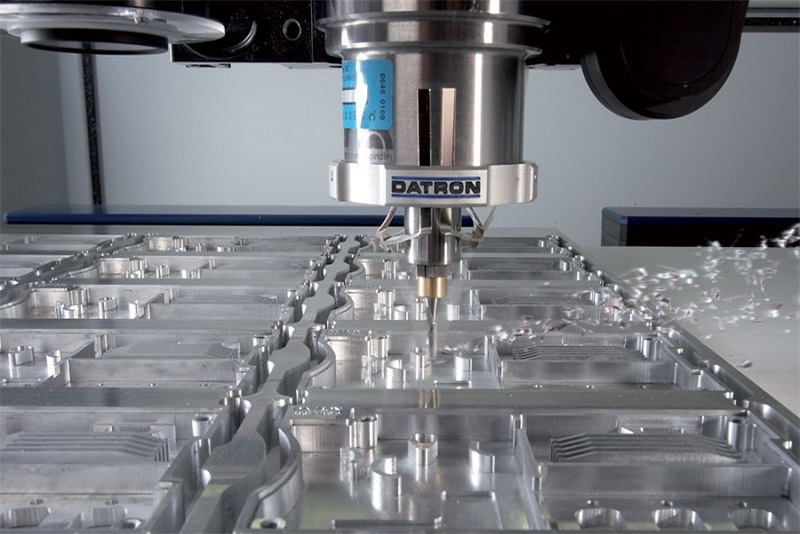

TEAM Rapid is one of the best manufacturers who offer injection molding services, CNC machining services for your prototypes to volume custom parts demand, contact our team today to learn more about us.