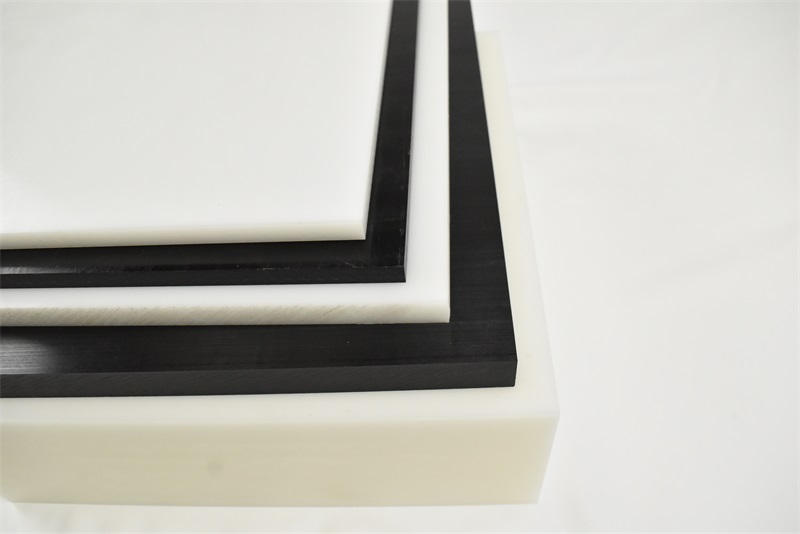

Delrin plastics are common thermoplastic materials used by manufacturers to create durable parts and components with excellent dimensional stability and various resistances. Manufacturers can use the the plastic materials as the basic materials in extrusion, injection molding, and CNC machining processes. This guide will help you understand more about the the plastic characteristics and applications.

Table of Contents

What are Delrin Plastics?

What is Delrin? Delrin is a brand name for the synthetic plastic polymer material called Polyoxymethylene (POM) or acetal, which you can use as a basic material for injection molding and other manufacturing processes. This is also a type of thermoplastic material that you can use in various applications, such as in construction, medical, automotive, packaging, fashion, and many other industries.

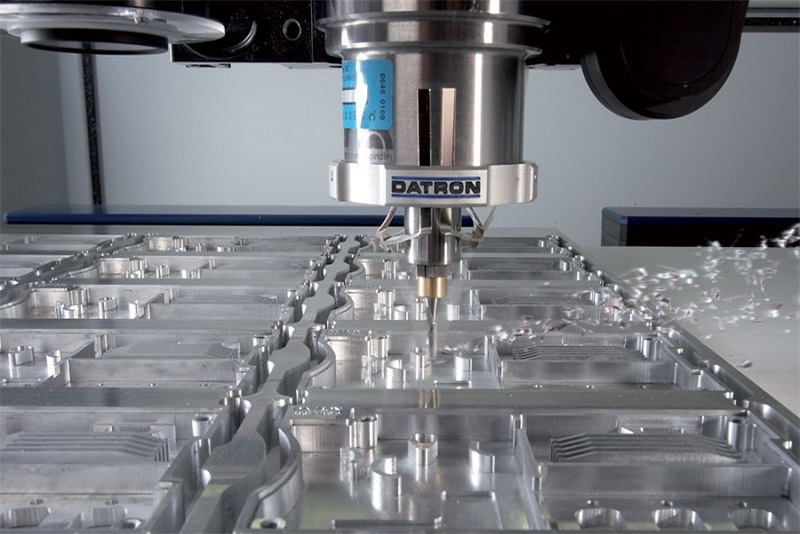

You can produce various rapid manufacturing parts and components by applying pressure and heat on the Delrin materials, such as during the extrusion and injection molding process. You can also use this material for CNC machining by first turning the Delrin materials into bars and sheet by using the extrusion process.

What is Delrin, and The Characteristics of Delrin Plastics

Delrin plastics have various characteristics that make them suitable to use for various applications. This plastic material is durable, and it also has an excellent dimensional stability to keep it in its original shape for long-term use. Here are the characteristics of Delrin plastics:

●Delrin plastics have Excellent dimensional stability.

Delrin has excellent dimensional stability, meaning that you can keep the shape of the rapid prototypes, parts and components intact, despite the environmental conditions. It is resistant to damage, and it is long-lasting.

●delrin plastics have Excellent hardness and durability.

The resulting parts and components made from Delrin plastics will also have the best hardness and durability when you compare it with other types of plastic materials. It is difficult to melt or deform after you complete the fabrication process of this material.

●delrin plastics have Low friction.

The plastics also have a low coefficient for friction, meaning that it is easier for you to use this material to create parts and components that will work well with other components. This is also the reason this material is best to use for making mechanical gears by CNC milling.

●Delrin plastics have Moisture resistance and low water absorption.

With Delrin plastics, you don’t need to worry about the parts and components getting faulty because of moisture or water damage. This material is moisture resistant, and it has a low water absorption level, meaning that the parts and components you make with this material will still work well in a humid environment. The material is suitable for mass production especially by injection molding services.

●Delrin plastics have Wear and chemical resistance.

Another excellent characteristic of Delrin plastics is that it also has resistances against wear and various chemicals. So, the parts and components made from this material will last for a long period, and you can use it even in a chemical-intensive environment.

Pros and Cons of Delrin Plastics

Pros

●You can create parts and components for various devices and equipment with Delrin plastics, which can work well with other components in the same system.

●Parts and components made with Delrin plastic materials are long-lasting, durable, and lightweight.

●Components created with the Delrin plastic materials can also withstand various chemicals, wear and tear, moisture, water leak, and other environmental damages.

●This material has excellent dimensional stability, which means you don’t need to worry about your parts and components getting deformed or becoming out of shape with regular use.

●You can use Delrin plastics to create both small and big parts and components in a wide range of industries.

Cons

●You cannot bond Delrin plastics with other materials.

●Delrin plastics also have low resistance against acids.

●The Delrin plastic materials can be very flammable, and it will be difficult to extinguish the flame with the regular fire extinguisher.

●Delrin plastics cannot withstand heavy abrasions, which means you can’t use this material in heavy construction.

Delrin Plastics Applications

You can use Delrin plastics as the base material for variousparts and components in a wide range of industries. The most common applications of Delrin plastics are for the mechanical gears and minor components, which you can use to work with other components in a wide range of devices and equipment. There are still plenty of other applications of Delrin plastics. Here are various Delrin plastic applications:

●Mechanical gears.

This is perhaps the most common use of Delrin plastic materials in industrial applications. You can use Delrin plastics to produce mechanical gears for vehicle engines, hardware parts for electrical equipment, nuts and bolts, and other components.

●Electronic parts.

There are various electronic parts that also use Delrin as the basic materials to create minor components, which will work together in various electronic devices, such as smartphones, tablets, computers, laptops, and others.

●Model toys.

You can also use Delrin plastics to produce various model toys used as merchandise for various popular brands, both for kids and adults. Manufacturers use Delrin plastic materials to create model toys in various shapes and sizes, which include vehicle model toys, railroad parts, character model toys, and more. Model toys that use Delrin plastic materials will often have more durable parts, which is great for long-term use.

●Medical equipment in Delrin plastics .

Some medical equipment also uses Delrin plastic materials as the basic materials for its components, such as for inhalers and insulin pens. The Delrin plastic materials are best to use for certain medical equipment because of their resistance to a wide range of chemicals and other environmental conditions.

●Furniture in delrin plastics.

Some furniture components, such as hinges, lock mechanisms, and sliding gears, use Delrin plastics as the basic materials for their production. Delrin plastics can also help keep the furniture lightweight, which is great if you want to have minimalist furniture at home.

●Others in delrin platics.

You can also use Delrin plastics in other applications, such as packaging, sports accessories, food-related equipment, zippers in clothing, and many others. The applications of Delrin plastic materials will keep on expanding.

Conclusion

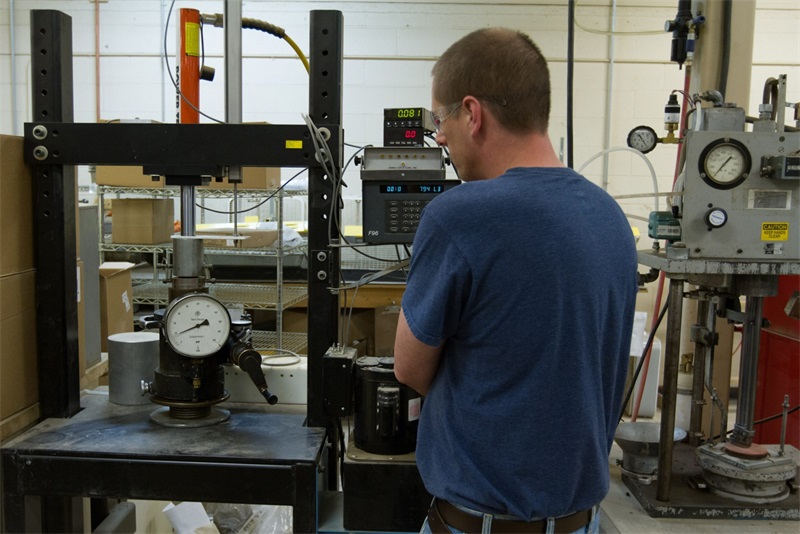

Delrin plastics are thermoplastic materials you can use in the plastic molding and extrusion processes to create various parts and components in various devices and equipment. You can also use this plastic material in the CNC machining process for a more precise fabrication of your parts and components.

The Delrin plastic materials have unique characteristics that make them preferable to use as the basic materials for gears and other components in a wide range of industries, which include automotive, medical, construction, consumer electronics, and many more.

TEAM Rapid has helped many customers to make their Delrin prototypes and plastic parts successfully. We offer a series of manufacturing services such as CNC machining(CNC turning), injection molding(insert molding and overmolding), 3d print services etc to meet your needs of Delrin manufacturing. Contact us today to get a free quote now!