Some stainless steel materials have certain properties that are better than the others, such as having more chromium content and fewer iron elements. With stainless steel passivation, you can level up the stainless steel grade by adding more versatility and durability to it. Yes, it’s a simple process, but it brings significant differences when you use it.

Table of Contents

Benefits of Passivation

The passivation of stainless steel involves a process of improving various properties of the stainless steel materials, along with providing you with many other benefits. The benefits of passivation for stainless steel include better machinability, better corrosion resistance, better surface aesthetics, and creating a purer form of stainless steel.

Here are the benefits of passivation:

●Better level of machinability.

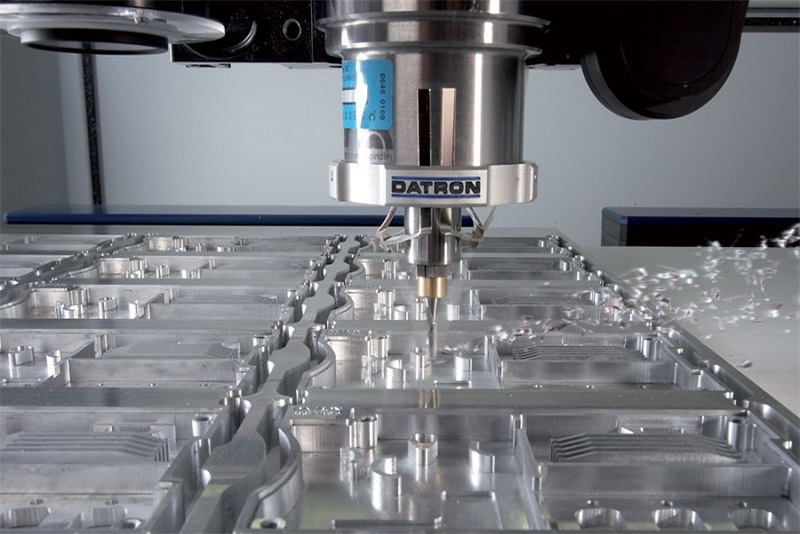

By passivating, you will make the stainless steel much easier to machine using the CNC machining-related techniques. With a greater level of machinability, cutting or drilling the stainless steel materials will not be much of a problem during the machining process. It makes for the ideal material work piece for your CNC prototyping activities.

●Better level of corrosion resistance.

Regular stainless steel materials are still not quite free from corrosion. By passivating the stainless steel, you can add a new layer of corrosion-resistance properties, making it much more resistant to corrosion.

●Purer form of stainless steel.

The regular stainless steel might still contain elements that can cause corrosion in the metal itself, such as iron. When you passivate stainless steel, you will further reduce the iron elements from the surface of the stainless steel metal. Also, you will add more chromium elements to protect the stainless steel further from corrosion, making it the purer form of stainless steel.

●Much better surface aesthetics.

With passivation, you can also improve the aesthetics of the stainless steel surface. Most regular stainless steel will still look dull on the surface, whereas the passivated stainless steel will look shinier and better aesthetically on the surface. The passivated stainless steel will look much better when you put them outdoors and as decorations for various buildings.

●Increasing the stainless steel grade quality.

Passivated stainless steel will become graded at a higher grade level, as it contains more chromium content on the surface. It can become a base material for various CNC prototyping activities, which can help produce higher-quality rapid prototypes or product samples.

How About Passivation Stainless Steel’s Durability and Versatility?

The passivation process of stainless steel is actually an optional process you can apply to the stainless steel material or alloy. Stainless steel itself is already corrosion-resistant, with better durability and versatility compared to the iron alloys or regular steel. However, the passivation process can improve the stainless steel properties even further, making it to become a higher grade of stainless steel.

Passivation can help improve the durability of stainless steel because it can accommodate the creation of more chromium layers around the stainless steel surface. This chromium layer addition can help increase the overall durability of the stainless steel material, along with improving its corrosion-resistance property.

Also, passivation can help improve the versatility of stainless steel(including die casting stainless steel), meaning that you can make the stainless steel more adaptive to various types of situations. This versatility improvement can help make the stainless steel even more long-lasting, and you can use this material for even more applications in various environmental conditions. It is all thanks to the reduction of iron elements and the increase of chromium elements on the stainless steel surface during the passivation process.

Brief Process Explanation of Stainless Steel

The process of passivation involves degreasing and immersing the stainless steel alloy into a special bath chamber. This process should be very straightforward and should complete quite fast, as it doesn’t involve any complicated steps to do.

Here’s the brief process explanation of Passivation Process:

- Degreasing and rinsing process.

The first step is degreasing, a process of removing impurities from the stainless steel surface, such as undesired contaminants. Degreasing uses a special chamber where you boil the stainless steel metal to remove all its contaminants. After that, you will need to rinse the stainless steel metal using the steam produced from the degreasing chamber.

- Passivation process in the bath chamber.

After the degreasing process is complete, you can then perform the passivation process, also in a special passivation bath chamber. You will need to immerse the stainless steel metal in the bath chamber containing citric acid or nitric acid to start the passivation process. In this process, the stainless steel surface will get some changes in their properties, including improved durability and versatility.

- Rinsing and drying process after passivation.

After completing the passivation process, you can rinse the stainless steel metal to remove and clean all acidic elements from the metal surface. Water is a viable cleaner to carry out the rinsing process. Once the stainless less metal becomes clean and dry, it means that it has completely been passivated.

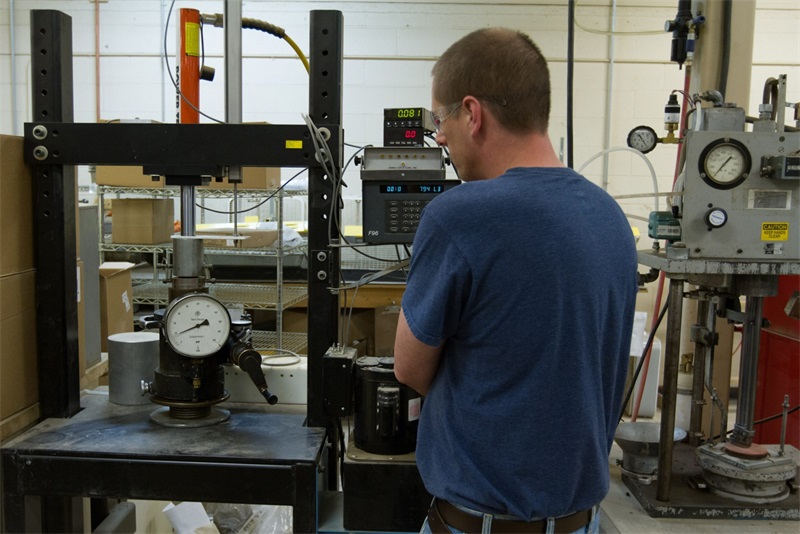

- Testing process.

You can test the properties of the passivated stainless steel to see if the new properties have been added, such as better corrosion-resistance and improved durability. After completing the testing process, you can use the passivated stainless steel for your manufacturing process.

The passivation process is quite simple to do, and it doesn’t require complicated steps or a big budget to perform. Little preparations are enough to help you go through the passivation process with no problems.

Conclusion – Improving Stainless Steel Durability and Versatility with Passivation

If the regular stainless steel doesn’t look too good for you, then passivation can help you improve the overall quality of the regular stainless steel in a simple way. With passivation, you can add more durability and versatility of the stainless steel metal you have, allowing you to use it for more long-term applications. The durability and versatility after passivated can also help you with increasing the overall value of the stainless steel metal, making it possible for you to make more profits from the products you are making with it.

TEAM Rapid offers a series of steel and post finish to meet your projects needs. We can make your custom parts by rapid manufacturing, die casting, and injection molding in any volume. Contact our team today to request a free quote now.