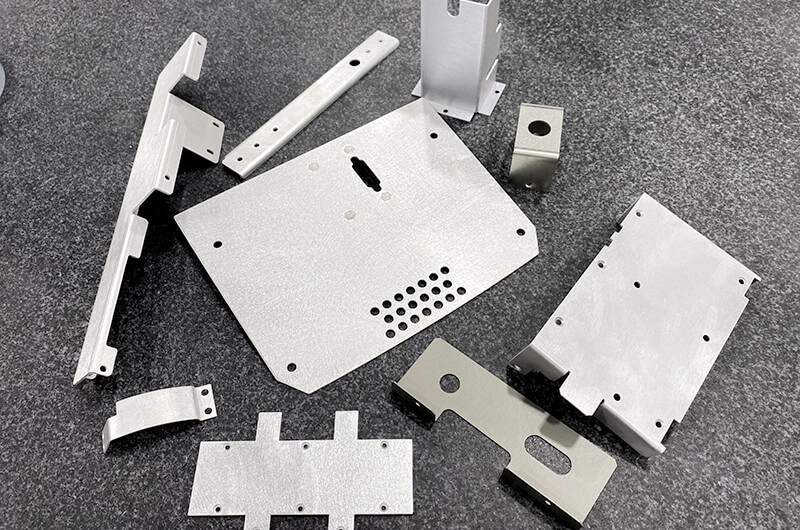

Building product samples for your industrial application will be much easier with sheet metal prototyping. It can provide you with various benefits in your manufacturing project. You can use different sheet metal materials to get the job done. It gives you the utmost flexibility in the design process to work on your project based on your production requirements.

Table of Contents

Let’s delve deeper into the benefits of sheet metal prototyping in the design process.

Product Testing

Sheet metal prototyping allows for continuous testing during the design process. The continued testing process will serve the purpose of perfecting the end product. You can find various product flaws during the continued testing process during different types of metals selection and sheet metal prototyping. It will serve as your evaluation in making your final product usable for the customers.

Without continuous testing, your final product will be full of errors and flaws when you release it to the market.

Design Process: Aesthetic Improvements

Another benefit of sheet metal prototyping in your design is the aesthetic aspects of your final product. Rapid prototypes carry a rough design idea about your final product. It might be usable like the final product. But it is not the final product itself. You can use the sheet metal prototypes to assess the aesthetic aspects of your final product before launching it.

You can apply various improvements to the aesthetic aspects with surface polishing, painting, and more.

Feature Additions

Adding and removing features from your final product will be easier with sheet metal prototyping. Sometimes, it’s best to simplify your product design by discarding certain features from the product. Want to improve the product quality? You can add more features to the product with sheet metal fabrication.

Including extra features or discarding old features can bring you various new insights about the product. You can build your final product to perfection in this way.

Design Process: Mechanical Improvements

Do you think that your prototype might be too weak mechanically? You can improve the mechanical aspects of your product using the sheet metal prototype. For instance, you can replace some materials with a more durable one. It can improve the technical specifications of your final product.

Mechanical improvements can also add new characteristics to your final product. It can benefit your product for the long term.

Improve Cost Effectiveness

Customizing your product via sheet metal prototyping can also help improve the cost-effectiveness factor of it. Sometimes, you need to test the material aspects of the product to find the most affordable solution. The goal is to replace the materials with cheaper ones without removing any of their functionality.

You will get the best product specifications that fit your budget better. A cheaper production cost means a more affordable product price for your customers.

Design Process: Eliminate Any Potential Issues

Building prototypes gives you a big idea about your final product. Sheet metal prototypes are almost identical to the final product. However, you can use the prototypes to find out about any potential issues that might happen. Finding potential issues will help prevent problems with the final product before launch.

Sheet metal prototyping allows you to eliminate potential issues during the product testing phase. You can find the solutions to these issues before releasing the final product. It can help save you a lot of money dealing with customer complaints later.

Prevent Any Costly Mistakes

Product defects and deformations can cost companies a lot of money to fix. A poor decision in product design will lead to various mistakes in manufacturing. It is one reason sheet metal prototyping becomes essential in your production cycle. It allows you to prevent any costly manufacturing mistakes before producing the final product.

Investing in sheet metal prototyping means securing your manufacturing production for the final product. It will minimize any chance of defects and deformations in your final product. Also, it will boost your production success rate.

Design Process: Improve the Quality of the Final Product

The success of your final product depends on its overall quality. The product’s capability and features also play a role in the product’s success. Sheet metal prototyping can provide an avenue for improving your product’s quality. You can launch the final product with all its best features and functionality.

You can create various iterations of the final product and test them for the best functionality. Pick a winner from these samples and put it into mass production.

A Higher Potential for Success in the Market

The more improved your product, the better the market will accept it. Product research costs a lot of money. You don’t want to end up with a failed product that the market will reject. Sheet metal prototyping helps you to build a successful product that the market will receive.

You can improve your product over time based on the user feedback you receive during the sheet metal prototyping process. It’s the best way to create a successful product for your target market.

Build a More Reliable Assembly for the Final Product

Sheet metal prototyping can also help perfect the assembly process for the final product. Unreliable assembly chains can lead to product defects and various other problems. Perfecting the assembly process is one way to build a more durable product.

You can test your assembly line and find any potential issues with sheet metal prototyping. Then, you can formulate the best rapid manufacturing solution for that.

Conclusion of Sheet Metal Prototyping in Design Process

Sheet metal prototyping is a beneficial production process you can’t live without. In manufacturing, you can use sheet metal prototyping to create product samples that can help improve your final product quality. It is also essential for the quality-checking aspect of your final product. With sheet metal prototyping, you can release the best version of your product to the market. You can also build the best user experience for the customers.

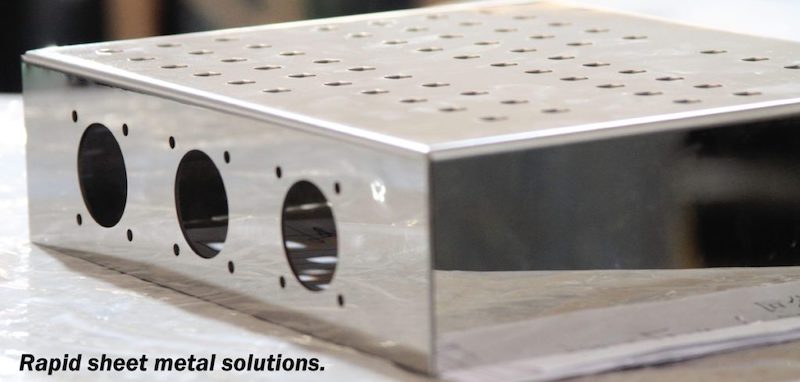

Sheet Metal Prototyping with Team Rapid

At Team Rapid Tooling, we provide various manufacturing solutions for clients worldwide. We are a professional custom-manufacturing company that can work on custom manufacturing projects. We can work to satisfy your project requirements in sheet metal prototyping and sheet metal forming. Contact us to discuss your project requirements.