Within the manufacturing landscape, injection molding stands as a pivotal technique for the mass production of plastic parts. This intricate process, both captivating and complex, holds significant sway over multiple industries. Delving into its mechanics, particularly the elusive cycle time uncovers pathways to enhanced production efficiency and fiscal advantages. This exposition embarks on a comprehensive exploration of the enigmatic cycle time within the realm of injection molding.

Table of Contents

- 1 Mastering Injection Molding: Unveiling the Process and Cycle Time Dynamics

- 2 Unraveling the Dynamics: Cycle Time in Injection Molding

- 3 Unveiling the Choreography: Factors Shaping Injection Molding’s Cycle Time

- 4 Part Design And cycle time

- 5 Refining the Cadence: Enhancing Cycle Time in Injection Molding

- 6 Save the Molding Costs by Reducing the Cycle Time

- 7 Conclusion of injection molding cycle time

- 8 Contact Us

- 9 Injection Molding Cycle Time – FAQs

Mastering Injection Molding: Unveiling the Process and Cycle Time Dynamics

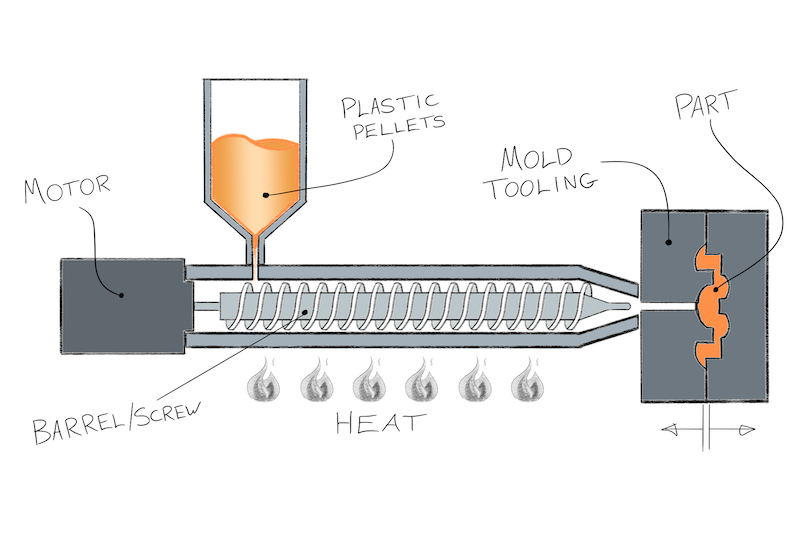

In the realm of manufacturing, injection molding reigns supreme as the go-to method for crafting parts on a grand scale. This captivating dance of creation involves injecting liquefied material into a mold, where it transforms from fluid to solid, birthing the desired component. This versatile technique finds its canvas in an array of materials, from metals to glasses, and even the beloved thermoplastic and thermosetting polymers. The journey of plastic molding unfolds through several distinct stages, each playing a crucial role in crafting perfection:

Clamping

The mold halves join hands, embracing the magic about to unfold.

Injection

Heat coerces the polymer into liquid surrender, and it eagerly fills the mold’s embrace.

Cooling

Patience takes form as the molten polymer morphs into its solid self, honoring the mold’s contours.

Ejection

The masterpiece emerges from its cocoon, ready to dazzle the world, often with finishing touches to enhance its allure.

In this intricate ballet, where every move matters, the cycle time emerges as the maestro, orchestrating the rhythm of efficiency. This enigmatic duration encapsulates the full swing of the injection molding pendulum – clamping, injecting, cooling, and finally, ejection. Efficiency hinges on the art of synchronizing these steps, and the cycle time’s heartbeat is the pulse of productivity. In essence, comprehending this cycle time symphony unlocks the door to injection molding’s mastery, where science, art, and precision unite in a harmonious production crescendo.

Unraveling the Dynamics: Cycle Time in Injection Molding

Cycle time in injection molding is akin to the heartbeat of the process. It encompasses the full span of a single journey through the molding routine. From the initial clasp of the mold’s embrace to the final closure before the next endeavor begins, it envelops the pivotal phases of injection, cooling, and ejection.

Fueling the Rhythm of Efficiency

Cycle time is the compass guiding the course of injection molding’s efficiency. It’s the timekeeper, the pacer, and the conductor all in one. A compressed cycle isn’t just a testament to speed; it’s the linchpin of production rates. With a shorter cycle time, parts multiply, productivity soars and the manufacturing arena hums with vibrant life.

The Dance of Quality and Pace

But, this journey isn’t just about racing against the clock. Quality waltzes in tandem with speed. Forging exquisite parts requires time for cooling, allowing the material to solidify perfectly. Rushing this delicate process could birth defects and imperfections, tarnishing the grace of the final creation.

Balancing the Budget by adjusting Cycle time

Cost efficiency also shares the stage with cycle. A swift cycle means less energy spent per part, nudging operational costs to a graceful low. The symphony of optimization plays out as manufacturer’s finesse the cycle time, seeking the sweet spot where quality, productivity, and budgetary harmony intersect.

Unveiling the Choreography: Factors Shaping Injection Molding’s Cycle Time

The grandeur of the rapid tooling and mold’s design holds sway over the tempo. Complexity might extend the cycle, granting time for intricate forms to solidify flawlessly.

Material Properties

Materials enter the stage with their unique traits. Swift solidification materials might bow to a quicker cycle time, while others, more leisurely, contribute their rhythm.

Molding Conditions

In this orchestra of creation, molding conditions take center stage. Injection speed, back pressure, and melt temperature become the conductors, orchestrating the harmony of speed and quality.

Machine Capabilities

The machine’s capabilities perform as supporting actors. The strength of its clasp, the force of injection—it all influences the cadence of completion.

Part Design And cycle time

Part design whispers its melody. Thin walls waltz to a quicker tune, their swift cooling reducing the cycle’s duration. Each factor plays its note, composing the symphony of cycle time. But this composition extends beyond the stage, impacting the broader production picture.

Balancing Efficiency and Output by adjusting cycle time

Imagine a scenario where a rapid-cooling material propels a swifter cycle. Yet, if haste leads to a surge in faulty pieces, efficiency falters. Likewise, an intricate mold design might extend the cycle, yet its intricate allure elevates the end product’s value. In this delicate dance, where speed, quality, and yield perform together, each factor plays a part. A material’s cool elegance, a mold’s elaborate embrace—they mold not only the part but also the process’s rhythm.

An Orchestra of Optimization

The symphony of cycle time reveals that it’s not just about speed. It’s about the interplay, the harmony between diverse elements. Mold, material, conditions—they step in unison to craft efficiency’s melody.

Refining the Cadence: Enhancing Cycle Time in Injection Molding

Optimizing cycle time in injection molding entails an amalgamation of calculated strategies:

Material Selection

The choice of material carries substantial weight. Opting for materials with expedited cooling properties can orchestrate a swifter cycle. Nevertheless, this must harmonize with the material’s compatibility for the intended part application.

Process Parameter Optimization

A symphony of adjustments is at play. Fine-tuning molding conditions, encompassing injection speed, back pressure, and melt temperature, compose the melody of cycle time. Often, this symphony involves a meticulous process of trial and refinement to arrive at a harmonious tempo.

Machine Maintenance

Regular maintenance of the injection molding machine directs the ensemble’s consistency. Ensuring the machine operates at peak efficiency orchestrates seamless transitions within the cycle.

Leveraging Technology

The integration of advanced methodologies, such as computer-aided engineering (CAE), ushers in an era of innovation. This technology orchestrates intricate simulations, harmonizing the composition of potential time reduction.

Harvesting the Benefits

Optimizing cycle time echoes a well-coordinated symphony; its benefits resonate in multifaceted chords. The crescendo of productivity reverberates as more parts pirouette through time. Simultaneously, a harmonious note of cost-effectiveness is struck, curtailing energy consumption per part. However, the underlying axiom remains steadfast: the quality of the final piece must never waver.

A Harmonious Convergence

In this meticulously orchestrated symphony of optimization, no instrument plays in solitude. Mold design, mold flow analysis, material choice, parameter calibration, and technological integration—all contribute to the tempo of the cycle. The aspiration is a magnum opus—efficient, economically viable, yet unwavering in quality. The symphony of cycle time spins a tale where innovation and precision twirl hand in hand, ultimately crafting a virtuoso performance.

Save the Molding Costs by Reducing the Cycle Time

It is one of the most effective ways to cut per-part cost by reducing injection molding cycle time, especially for medium- to high-volume production. Below is a practical table, factory-proven guide, organized by the stages that dominate cycle time.

| Area | Optimization Method | What to Do | Why It Reduces Cycle Time | Cost Level | Typical Cycle Time Reduction |

|---|---|---|---|---|---|

| Cooling System | Conformal cooling | Use 3D-printed cooling channels that follow part geometry | Improves heat removal efficiency | Medium–High | 20–40% |

| Cooling System | Optimize cooling channel layout | Place channels closer to cavity, balance circuits | Eliminates hot spots and uneven cooling | Medium | 15–30% |

| Cooling System | Turbulent water flow | Increase flow rate (Re > 4000) | Enhances heat transfer | Low | 5–15% |

| Cooling System | High-conductivity inserts | Use BeCu or aluminum inserts | Faster heat dissipation | Medium | 10–25% |

| Part Design | Reduce wall thickness | Thin non-critical sections | Thinner walls cool faster | Low | 15–30% |

| Part Design | Uniform wall thickness | Avoid thick-to-thin transitions | Prevents over-cooling and sink | Low | 10–20% |

| Part Design | Use ribs instead of thick walls | Replace mass with structural ribs | Maintains strength with less material | Low | 10–20% |

| Material Selection | Lower melt-temperature resin | Switch to faster-cooling polymers (PP, PE, ABS) | Shortens cooling and packing time | Low–Medium | 10–25% |

| Material Selection | Higher thermal conductivity resin | Select filled or optimized grades | Improves heat transfer | Medium | 5–15% |

| Process Parameters | Optimize cooling time | Set cooling just above ejection temp | Eliminates over-cooling | None | 5–15% |

| Process Parameters | Reduce packing time | Perform gate freeze study | Avoids unnecessary hold time | None | 5–10% |

| Process Parameters | Lower melt temperature | Use minimum stable melt temp | Faster solidification | None | 3–8% |

| Mold Construction | Reduce mold open/close stroke | Minimize daylight and eject distance | Shortens non-productive time | Medium | 5–10% |

| Mold Construction | Replace hydraulic actions | Use mechanical or electric slides | Faster, more consistent movements | Medium–High | 5–15% |

| Mold Construction | Improve venting | Add vents or vacuum venting | Faster filling and packing | Low–Medium | 3–8% |

| Ejection System | Increase draft angles | ≥1–2° minimum | Easier, faster ejection | Low | 3–10% |

| Ejection System | Use air or stripper ejection | Assist part release | Prevents sticking delays | Low–Medium | 3–8% |

| Mold Strategy | Multi-cavity molds | Produce multiple parts per cycle | Lowers cost per part without longer cycle | High | Cost per part ↓ 30–70% |

| Automation | Robotic part removal | Remove parts immediately at mold open | Eliminates operator delay | Medium | 5–10% |

| Quality Control | Reduce scrap rate | Stabilize process, monitor pressure | Prevents wasted cycles | Low–Medium | Indirect but significant |

Conclusion of injection molding cycle time

In drawing the final curtain on this discourse, a mosaic of strategies and factors comes into view, all converging on the pivotal theme of optimizing cycle time. From meticulous mold design to calculated material choices, every element partakes in the orchestration. Recognizing and fine-tuning this choreography isn’t just a technical endeavor; it’s a harmonious mastery that aligns productivity, efficiency, and quality in a resounding crescendo.

Contact Us

Want to learn more about injection molding cycle time or want support with your plastic parts production? TEAM RAPID is here to help you with, our experienced team can help you to optimize your design and suggest the best manufacturing parameters for molding, we can help from from prototype tooling to low-volume injection molding and beyond.

📧 Email: [email protected]

📞 Phone: +86-760-8850-8730

Whether you’re exploring ways to reduce cycle time, improve part quality, or get a free quote for your project, we’ll provide fast, expert guidance — just send us your part files or inquiry today! Besides from injection molding, TEAM Rapid also offers rapid prototyping, 3d printing services, and die casting to meet your projects needs. Contact our team today to request a free quote now!

Injection Molding Cycle Time – FAQs

1. What is considered a “good” cycle time in injection molding?

As a general guideline:

- Small, thin-wall plastic parts: 15–30 seconds

- Medium-size parts with standard wall thickness: 30–60 seconds

- Thick-wall or engineering plastic parts (PC, Nylon, etc.): 60–120 seconds or longer

Cooling time typically accounts for 50–70% of the total cycle, so parts with thicker walls or higher melt temperatures naturally require longer cycles.

2. Which stage of the injection molding cycle takes the longest?

Cooling time

It is usually the longest stage, often accounting for 50–70% of the total cycle time. This is why mold cooling design, material selection, and wall thickness have the greatest impact on cycle time reduction.

3. How does wall thickness affect injection molding cycle time?

Cycle time increases exponentially with wall thickness. Thicker walls retain heat longer and require extended cooling. Reducing wall thickness by even 10–20% can significantly shorten cycle time without affecting part strength if ribs or gussets are used correctly.