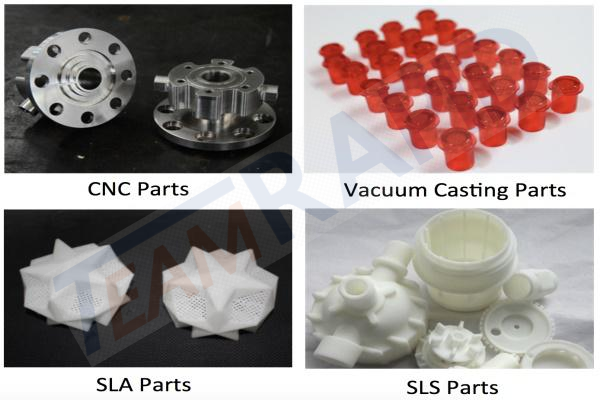

There are many ways to perform low-volume manufacturing. Such as CNC machining, 3D printing, rapid tooling and vacuum casting. Low volume manufacturing is a bridge from prototype to mass production. TEAM Rapid is a leading manufacturer that offers low-volume manufacturing services. Our experienced experts ensure high quality and repeatability of each part. We are able to provide cost-effective and suitable suggestions for design, materials, production process and manufacturability.

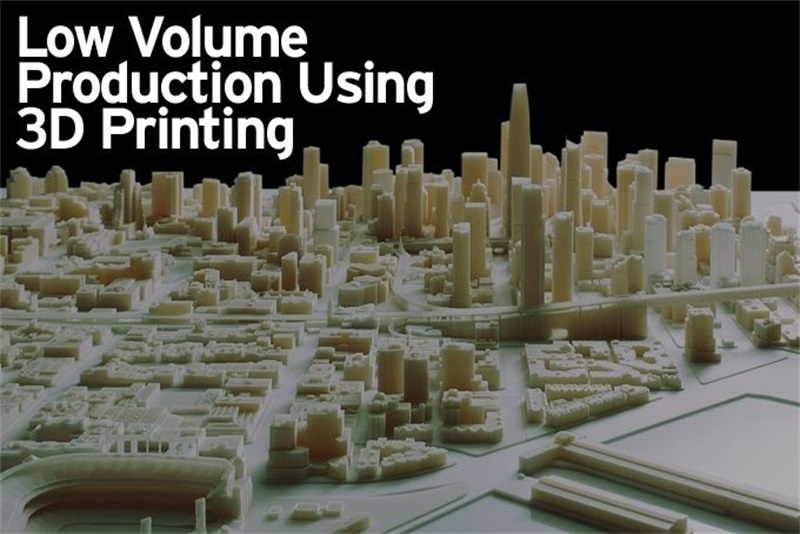

Today, people want more customized products. Flexible innovation and fast time to market are important to manufacturing. Low volume manufacturing is suitable for production quantity of 100 to 100k units. Low volume manufacturing reduce risk, allows more flexible design and fast product launch time. Compared to large volume production which needs high initial investment, low volume manufacturing offers chance to save production cost. Low volume manufacturing methods benefit customers, manufacturers and stakeholders from design to manufacturing.

Low-volume manufactuing allows many benefits. Before running into mass production, manufacturers need to spend money in expensive production mold investing. Manufacturers can verify design, assembly and manufacturability by building low volume product runs. Design will be optimized and improved after the initial trial run. Mold cost and design cost are playing a key role in project budget. Low Volume Manufacturing more cost effective compared to mass production because of its speed and short cycle time. Before running into mass production, producing hundreds or thousands of parts as pre-production trial is a useful step. It will narrow the gap between prototype and production. Functional, shape matching test and design can be verified quickly. Potential problems could be found and fixed before mass production. Low-volume production also reduces the time to markets.

Application of low volume production includes production-level part to match functional prototypes with final parts; pre-production part for test validation; high quality customized parts; fast part with limited budget needs etc.

Depending on industries and parts are going to be manufactured, pat can be produced using rapid tools or independent manufacturing technologies like 3D printing, CNC machining or vacuum casting.

Low Volume production Service minimizes the risk of your projects. Its fast design validation leads to early revenue funding, providing funds for improved design. For more information on low-volume services, contact us at [email protected] today.