Custom Plastic Injection Molding Services

At TEAM Rapid, we specialize in high-quality plastic injection molding services for customers across the USA, Europe, and beyond. Whether you need rapid prototyping, low-volume production, or full-scale manufacturing, we offer cost-effective and fast-turnaround solutions tailored to your unique project requirements. With state-of-the-art equipment and ISO-certified quality systems, we deliver precision-molded plastic parts with tight tolerances and excellent repeatability—perfect for medical devices, automotive components, consumer products, and industrial equipment.

Our Injection Molding Services

Rapid Prototype Injection Molding

Speed up your development cycle with prototype molds and pre-production testing. We help you evaluate design, material choice, and part performance before investing in full tooling.

Low-Volume & Bridge Production

Perfect for quantities between 100 and 10,000 units. Our low-volume injection molding allows you to go to market quickly while reducing costs compared to traditional tooling.

Overmolding & Insert Molding

We mold multiple materials or integrate metal inserts into plastic parts—ideal for tools, grips, connectors, and multi-functional components.

Multi-Shot / Two-Shot Molding

Improve part strength, function, and aesthetics with multi-material molding. Combine soft and rigid materials in a single process.

Thin-Wall & Medical Injection Molding

Specializing in thin-wall molding and cleanroom molding for healthcare and medical device components, we offer compliant solutions for highly regulated industries.

In these years, we help lots of customers to launch the market successfully starts from prototype tooling to mass production. We are pride to be their reliable injection molding supplier. Here are the comments from our customers, please check.

Plastic Injection Molding Process

Plastic injection molding is a highly efficient and cost-effective manufacturing method used to produce plastic parts in both low and high volumes.

The process begins by heating plastic pellets until they melt, then injecting the molten plastic into a precision-engineered mold cavity. Once the plastic cools and solidifies, the part is ejected, and the cycle repeats—often hundreds or thousands of times—making it ideal for mass production. Since the same mold is reused throughout the production run, the initial mold cost is spread across all parts, significantly reducing the cost per unit to just a few dollars—or even less for high-volume orders. Injection molding delivers parts with excellent dimensional accuracy and consistent quality from the first piece to the last. Compared to CNC machining or 3D printing, injection molding offers a wider variety of materials, color options, surface finishes, and cosmetic details, giving manufacturers greater flexibility in both function and appearance.

Workflow of Plastic Injection Molding Process |

|

| Step1: |

The molding plastic resin is usually in raw pellets, and after drying to the right moisture content. Pigments or master batch colorants are needed if necessary to get the correct color for design. |

| Step2: |

Pouring the pellets into the hopper of molding machine. The pellets will be heated and transported to the mold by a reciprocating screw inside the barrel of the machine. |

|

Step3: |

The barrel heats and mix the pellets until fully molten, forming the liquid resin. |

|

Step4: |

The resin is injected into the mold cavity(the heated mold closes automatically) through a injection molding gate under great pressure. |

| Step5: |

It takes a short whole to cool down the mold, and solidify the part inside. |

| Step6: |

The part is ejected after the mold opens, and to begin a new cycle |

Process Animation |

|

TEAM Rapid is a plastic injection molding company that provides on-demand prototypes, low-volume molding, and extensive volume production molding. We mold the plastic parts you need without design compromises at the correct price point. Our professional engineering team offers consultation on every injection molding quote and will efficiently move your projects from design to production.

Types Of Injection Molding Services At TEAM Rapid

TEAM Rapid is one of the best injection molding manufacturers in China; we work with various types of custom molding services to meet your low to high-volume needs

| Clear Plastic Molding | Insert Molding | |||

|

|

|

|

|

|

Exceptional transparency and highly versatile process, catering to industries where clarity and meticulous detail are paramount. |

Enhanced durability and seamless integration of multiple materials allow for the customization of parts by molding plastic around pre-placed inserts. |

Improved grip & aesthetics and efficient multi-material integration make it possible to mold a material layer over an existing part with additional functionality & design appeal. |

Ensure the accurate creation of high-quality threaded components, essential for the seamless assembly of parts and exact specifications. |

Unparalleled flexibility, heat resistance, and biocompatibility make them ideal for industries requiring materials that can withstand extreme conditions while maintaining integrity and performance. |

Injection Molding Applications Across Industries | TEAM RAPID

At TEAM Rapid, we specialize in delivering custom injection molding solutions for a wide range of industrial applications. With over a decade of manufacturing experience, we have partnered with global clients in the medical, automotive, consumer electronics, and industrial sectors to produce high-precision molded components that meet demanding quality and performance standards.

Injection molding is one of the most versatile manufacturing processes available today. It allows for mass production of complex plastic partswith tight tolerances, excellent surface finishes, and repeatable quality. Our expertise covers multiple industries and applications including:

Medical & Healthcare Devices

From housings and connectors to sterile, biocompatible components, injection molding ensures precision and cleanliness for life-critical products.

Consumer Products & Electronics

We produce durable, aesthetic plastic enclosures, buttons, and accessories used in appliances, wearables, and gadgets—combining function and design flexibility.

Automotive & Transportation

Lightweight, high-strength components such as clips, panels, and brackets help reduce vehicle weight and improve efficiency.

Industrial & Mechanical Equipment

Custom molded gears, housings, and mechanical parts offer superior durability and consistent performance in demanding environments.

Packaging & Home Goods

From cosmetic containers to reusable household items, injection molding offers low-cost, scalable production for large volumes.

Why Choose TEAM RAPID's Injection Molding Services

There are many plastic injection molding companies. Why should you choose TEAM Rapid's services and injection mold in China? Here are the reasons:

-

Extensive Experience– Over 10 years serving global clients with complex projects

-

Tailored Solutions– Each mold design is optimized for your product’s function and application

-

Fast Turnaround– Rapid prototyping and bridge tooling to accelerate your time-to-market

-

Material Expertise– Wide selection including ABS, PC, PA, POM, PP, and engineering plastics

-

ISO 9001:2015 Certified Quality– Rigorous inspection ensures your parts meet exact specifications

Our engineers understand that every industry has unique requirements. We combine technical insight with advanced manufacturing capability to deliver parts that meet your mechanical, aesthetic, and cost targets.

Flows of Our Injection Molding Progress

TEAM Rapids offers a one-stop plastic injection molding service that starts from inquiry to engineering supports, tool building, and injection molded parts delivery. In the past ten years, we have helped more than 500 customers to develop their parts successfully.

Injection Molding Capabilities and Options at TEAM RAPID

| Category | Details / Standards | Description & Applications | Key Benefits |

|---|---|---|---|

| Hard Plastics | ABS, ASA, PC, PMMA, PP, HDPE, POM, Nylon, Nylon+GF | Durable engineering plastics used for high-strength, heat-resistant, and structural components. | Excellent rigidity, dimensional stability, and chemical resistance. |

| Soft Plastics | TPE (various hardness), TPU (various hardness) | Used for flexible parts, grips, gaskets, and overmolding projects. | Superior flexibility, resilience, and ergonomic comfort. |

| Special Property Materials | UV-resistant, chemical-resistant, abrasion-resistant, impact-resistant, transparent, flexible | Custom compounds tailored for specific environments and performance needs. | Enhanced durability, performance, and visual appeal. |

| Material Supply & Certification | Data Sheet / COC / COA available | Reliable and traceable raw material supply chain ensures stable production quality. | Compliance with international standards and batch traceability. |

| Surface Finish – Polished | SPI (Society of the Plastics Industry) | Creates smooth or glossy surfaces suitable for optical or cosmetic parts. | High aesthetic quality and easy cleaning. |

| Surface Finish – Textured | VDI 3400 Series | Produces matte or spark textures for industrial and consumer applications. | Reduces glare, improves grip, hides flow marks. |

| Surface Finish – Patterned | Mold-Tech Equivalent | Adds decorative or functional surface patterns per customer request. | Custom texture options for branding or functionality. |

| Coloring – Low Volume | Pigment added directly into hopper | Cost-effective for prototypes and small batch runs. | Fast turnaround and lower material waste. |

| Coloring – High Volume | Pre-compounded custom material | Ensures precise color matching across large-scale production. | Consistent color tone and mechanical properties. |

| Coloring – Very High Volume | Masterbatch colorant | Ideal for mass production requiring strict color control. | Economical and repeatable for long-term manufacturing. |

| Dimensional Tolerance | Follows DIN 16742 unless specified | Precision manufacturing for stable and consistent part dimensions. | Reliable part fitment and interchangeability. |

| Visual Quality Standard | Defined by part visibility & application | Inspection criteria tailored to customer requirements. | Ensures both functional and aesthetic expectations are met. |

| Design Optimization | Mold flow & DFM analysis | Engineers evaluate potential issues like shrinkage, warping, or stress before production. | Reduced defects, faster lead time, and cost savings. |

| Additional Services | Thermoforming, Thermosetting, Overmolding, Insert Molding | Full-service injection molding capabilities for various industries. | One-stop solution from prototype to production. |

Contact TEAM RAPID today to discuss your project needs. Our technical specialists can help you select the ideal plastic material, surface finish, and molding process fro your application. Upload your drawings now for a free, no-obligation quote!

Post-Finish Services for Injection Molded Parts

At TEAM RAPID, we don’t just produce high-quality injection molded parts — we also provide a full range of post-finishing and surface treatment services to make your parts production-ready. Whether you need a glossy cosmetic surface, matte industrial finish, or custom color coating, our finishing solutions ensure your parts look professional and perform perfectly.

Why Post-Finishing Matters

Post-finishing plays a key role in the appearance, durability, and function of injection molded parts. After molding, surfaces may show tool marks, weld lines, or uneven gloss levels. Applying the right surface finish improves aesthetics, enhances wear resistance, and ensures better adhesion for paints, coatings, or labels. Choosing the right finish can also improve grip, texture, or branding value — helping your products stand out in the market.

Available Post Surface Finishes & Treatments at TEAM RAPID

TEAM RAPID offers a wide variety of injection molding surface finishes to meet your design, function, and cost requirements:

| Finish Type | Description | Benefits / Applications |

|---|---|---|

| Polishing & Texturing (SPI, VDI, Mold-Tech) | From mirror polish to matte or textured surfaces, depending on design and function. | Ideal for cosmetic parts, consumer products, and functional housings requiring smooth or uniform texture. |

| Painting / Coating / EMI Shielding | Spray painting, powder coating, or conductive coatings for protection or appearance. | Adds color, durability, and UV/chemical resistance while supporting branding needs. |

| Pad Printing / Laser Marking / Silk Screen | Adds logos, symbols, or identification directly on molded surfaces. | Great for branding, part labeling, and custom graphics. |

| Heat Staking / Metal Inserts | Adds metal inserts or threaded features after molding. | Improves structural strength and assembly performance. |

| Ultrasonic Welding / Assembly | Joins molded components securely after production. | Ideal for sealed enclosures, electronic housings, and multi-part assemblies. |

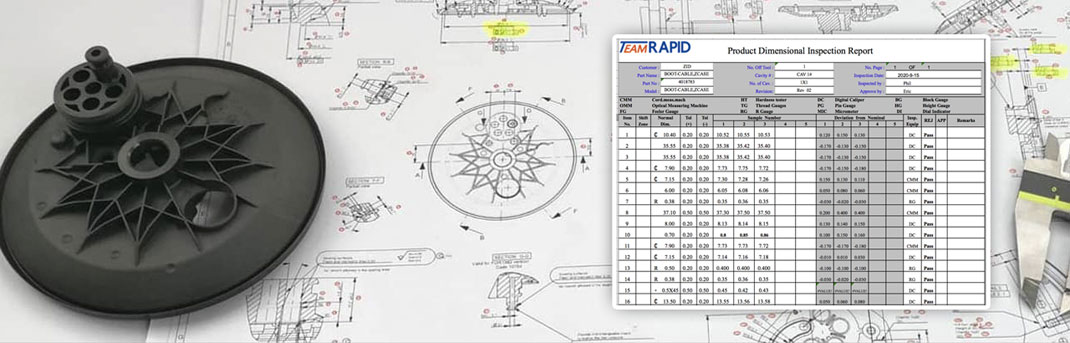

Quality Assurance: Report! Report! Report!

Injection molding services have always been one of our core services. Our company has advanced injection molding and testing equipment to provide stable, qualified parts. Contact us at [email protected] to learn more about our services.

Happy Customers - Trusted by Global Brand

At TEAM RAPID, we take pride in helping our clients turn ideas into real, high-quality plastic parts.Here’s what our customers around the world are saying about their injection molding experience with us:

“Outstanding Fit and Finish”

“The parts look very good and fit together perfectly. Thank you very much for the excellent work!”

— Manuel, Germany

“Reliable Partner for Global Manufacturing”

“Although there are many horror stories about manufacturing in China, my experience with TEAM Rapid has been outstanding.

Jason Zhu and Eric Chen have my unconditional trust. They are invaluable product development partners.”

— Larry Bell, USA

“High-Quality Rapid Manufacturing”

“I opened the package today and was very impressed with the quality of your work.

The attention to detail is incredible. I look forward to doing more projects with you soon. Thank you!”

— MB, Germany

High Mix Low-Volume Injection Molding at TEAM Rapid

TEAM Rapid is one of the best molding companies that offer complete services, from design concepts and prototyping to mass production. Our team of experts is always ready to guide you, including ideas, design, creation, soft plastic molds prototyping, production, testing, inspection, and shipping. Contact us now for your new High-Mix, Low-Volume Manufacturing project. Besides the services above, we also offer our customers custom silicone molds, silicone molding, injection blow molding, and DIY injection molding supports. You are looking for a manufacturer who offers plastic injection molding near me. You can try our fast delivery first.

Customized Injection Molding Cost - Overview

When it comes to custom injection molding, there is no universal price. Every project is unique, and the final cost depends on your specific part design, production volume, and quality requirements. At TEAM RAPID, we provide transparent pricing based on your needs — helping you balance cost, speed, and performance.

The total cost of custom injection molding can be divided into two main parts:

- The injection molding production cost(material, labor, machine time, finishing, etc.)

- The mold or tooling cost, which covers design and fabrication of the injection mold itself.

1. Injection Molding Production Cost

The cost of the full injection molding operation depends on the services you choose — from prototyping to mass production. This includes raw materials, molding cycles, post-processing, and inspection. At the end of production, you’ll receive high-quality molded parts that meet your exact specifications. Any optional after-sales services, such as product modifications, part redesign, or repeat production runs, may involve additional charges.

Key factors that affect production cost:

- Type and volume of materials used

- Cycle time and part complexity

- Number of cavities per mold

- Finishing and secondary processes (e.g., polishing, texturing, or painting)

2. Injection Mold Cost / Rapid Tooling Cost

The injection mold(or tooling) represents the initial investment in your production. This cost is typically separated from the part production cost and is payable after you approve the final mold design.

The mold cost varies depending on:

- The complexity of your part geometry

- The type of steel or aluminum used for the mold

- The expected production volume (prototype vs. high-volume)

Whether you choose rapid tooling or conventional mold manufacturing

Rapid tooling provides a faster, lower-cost solution for small runs or prototype validation, while traditional tooling offers maximum durability for long-term production.

3. Factors Affecting Custom Injection Molding Cost

Several important aspects influence the overall cost of your project:

| Factor | Description |

|---|---|

| Design Readiness & Complexity | A complete 3D model and DFM-friendly design help reduce revisions and costs. |

| Material Selection | Choice of plastic resin (ABS, PC, POM, Nylon, etc.) affects both part performance and cost. |

| Manufacturing Method | Rapid tooling is faster and cheaper for small runs, while conventional molds suit mass production. |

| Mold Design & Features | Multi-cavity molds, complex geometry, or tight tolerances increase tooling cost. |

| Lead Time Requirements | Urgent projects may require premium expedited production services. |

| Post-Processing & Branding | Finishing options such as pad printing, painting, or laser engraving can add cost. |

DIY Injection Molding vs. Outsourcing Services

When it comes to producing plastic parts, you have two main options:DIY injection molding or partnering with a professional injection molding service provider. Each approach has its advantages and limitations. Understanding the differences can help you make the best choice for your product development or production needs.

DIY Injection Molding

DIY injection molding allows individuals or small teams to produce parts in-house using small bench top machines or simple molding tools.

Advantages:

- Lower initial investment– Small machines and molds are relatively inexpensive.

- Hands-on learning– Ideal for prototyping or experimentation.

- Quick iteration– You can test designs immediately without waiting for a manufacturer.

Limitations:

- Part size and complexity– DIY machines are usually limited to small, simple parts.

- Material options– Limited to a few types of thermoplastics; specialized materials may not be available.

- Quality and consistency– Dimensional tolerances, surface finishes, and repeatability are hard to control.

- Time-consuming– Setting up molds, heating, and troubleshooting can slow down production.

DIY injection molding is best for hobbyists, small-scale prototypes, or educational purposes.

Outsourcing to Injection Molding Services

Outsourcing your injection molding needs to a professional provider, like TEAM RAPID, gives you access to industrial-grade equipment, expert engineering, and high-quality materials.

Advantages:

- High precision and consistency– Parts are manufactured to tight tolerances with professional inspection.

- Wide material selection– Hard plastics (ABS, PC, POM) and soft materials (TPE, TPU) with specialty properties.

- Scalability– Suitable for both low-volume prototypes and high-volume production runs.

- Advanced finishing options– Polishing, texturing, painting, pad printing, and assembly are all possible.

- Engineering support– Experts assist with DFM (Design for Manufacturability), mold design, and process optimization.

Limitations:

- Higher initial cost– Requires mold tooling investment, although cost is amortized over production volume.

- Lead time– Custom molds and production schedules may take days or weeks, depending on complexity.

Outsourcing is ideal for companies seeking professional quality, scalability, and reliability.

Which Option Is Right for You?

- Choose DIY injection molding if you are experimenting with designs, making small prototypes, or learning about the process.

- Choose outsourcing with a professional manufacturer like TEAM RAPID if you need high-quality, scalable, and reliable injection molded parts for business, industrial, or commercial applications.

At TEAM Rapid, we combine rapid tooling, professional engineering, and flexible production options to deliver injection molded parts that meet your exact specifications.

Frequently Asked Questions

What Is Injection Molding?

Injection molding is a forming process by injecting molten material into a mold to produce parts in small volumes to 1,000,000 +. It can be performed with various materials such as elastomers, glasses, confections, thermoplastic, thermosetting polymers, and metals(for which the process is known as die casting).

What Is Plastic Injection Molding?

Plastic injection molding is a branch of injection molding. It is a cost-effective and reliable method to produce solid and plastic parts and products in any volume. The process involves high pressure to force a molten liquid polymer into a hollow mold. It is removed from the mold when the polymer is cooled and solidified, and the cycle repeats. Every repeated process is called a shot. The more shots mean the more number parts you have gotten.

How Much Does injection Molding Cost?

Injection molding costs can be $100 or far more than $100,000. Part material, part size, order size, part complexity, mold cavity numbers, molding cycle time, labor cost etc are the factors that affect the costs. Injection molding can be cheap over the long run, but the unit part price is high to set up for a small volume. We usually suggest that clients go ahead with injection molding for quantities over 500+ needs, as it is cheap injection molding at that volume.

How Does Injection Molding Work(How Injection Molding Works)?

There are several steps for injection molding:

1. Get ready for the mold and injection material.

2. Pull up the mold and locate it on the injection machine.

3. Clamping.

4. Injection.

5. Dwelling and cooling.

6. Ejection.

7. Trim the gate if needed.

How to Make Injection Molds?

There are several steps to make injection molds:

1. Mold design.

2. Order steel and mold base.

3. Steel inspection.

4. Rough CNC process.

5. Heat treatment.

6. Fine CNC process.

7. Electrodes machining.

8. EDM & Wire EDM.

9. Polishing/Texture.

10. Mold components inspection.

11. Fitting & Assembly.

12. Mold trial.

Some steps can be parallel processed, such as we can do mold CNC machining and electrode machining in the meanwhile by two different machines. For prototype mold or bridge mold, heat treatment can be eliminated due to the less volume.

How Much Do Injection Molds Cost?

The mold cost ranges from 1000 USD to 100,000+ USD, which depends on the material, size, structure, complexity etc.

A simple, small, single-cavity open and closed steel mold can cost as little as 1000 USD.

A complex, large, multi-cavity, multi-sliders steel mold can cost upwards of 20,000 USD to 100,000+ USD.