2024: Plastic injection molding stands as a cornerstone in contemporary manufacturing, offering a revolutionary method to produce identical plastic parts with utmost precision. By injecting molten plastic into molds, it shapes parts mirroring the mold cavity. The cost-effectiveness and remarkable repeatability make this process an indispensable asset in various industries’ manufacturing endeavors.

Table of Contents

- 1 The Precision Dance of Plastic Injection Molding: Unveiling the Four Key Steps

- 2 A Palette of Possibilities: Materials for Plastic Injection Molding

- 3 Plastic Injection Molding: A Symphony of Applications

- 4 Mold Design: The Foundation of Excellence in Plastic Injection Molding

- 5 Conclusion of Plastic Injection Molding

The Precision Dance of Plastic Injection Molding: Unveiling the Four Key Steps

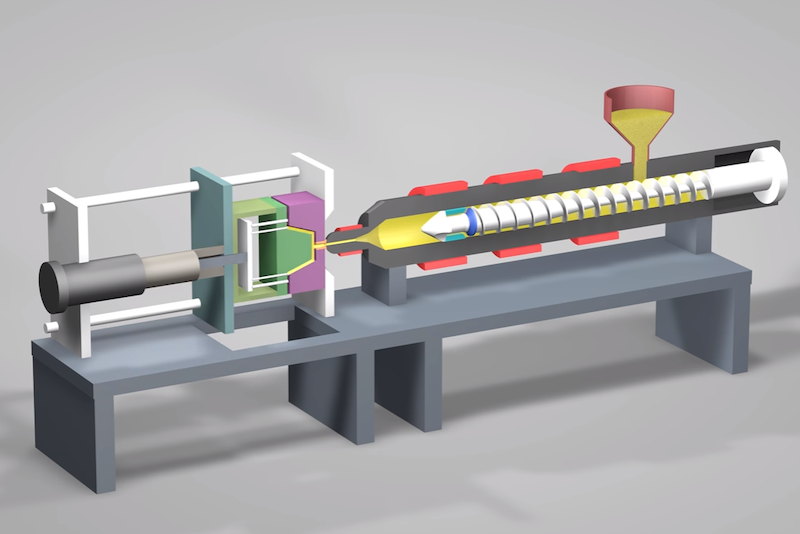

The artistry of plastic injection molding unfolds through a meticulously choreographed sequence of four pivotal steps. This captivating process showcases the seamless transformation of molten plastic into flawless, identical rapid prototypes and parts, executed with finesse and finesse, as the dance of clamping, injection, cooling, and ejection takes center stage.

Clamping – Forming the Stage

As the curtains rise, the first act commences with clamping, the union of the two mold halves, orchestrating the creation of a cavity resembling the envisioned part. This tightly bound stage is vital to contain the forthcoming molten plastic and facilitate impeccable molding performance.

Injection – Dynamic Fluidity

With the stage set, the spotlight shines on injection, the mesmerizing entry of molten plastic into the mold’s heart, fueled by high pressure. In an elegant fluidic motion, the plastic gracefully fills the cavity, taking shape in response to the mold’s design.

Cooling – Solidifying Symphony

As the fluid ballet unfolds, the mesmerizing cooling phase sweeps in, bestowing solidity upon the molten grace. With impeccable timing, the plastic cools and solidifies, intricately conforming to the mold’s contours, creating an enchanting symphony of shape and form.

Ejection – Applause of Completion

As the grand performance reaches its climax, the moment of triumphant ejection emerges. The two mold halves part ways, and the perfected creation emerges, gracefully bowing to the audience. The finished part is now free, ready to join its peers in the grand ensemble of production.

A Palette of Possibilities: Materials for Plastic Injection Molding

Within the realm of plastic molding lies a vibrant palette of materials, each with its unique allure. Embracing the spotlight, two remarkable categories take center stage: thermoplastic and thermosetting polymers, each infusing the art of rapid manufacturing with its distinct charm.

Thermoplastic Polymers

Gracing the stage as the stars of injection molding, thermoplastic polymers captivate with their remarkable adaptability. Their ability to soften and flow upon heating, coupled with ease of recycling, make them the go-to choice. From the flexible elegance of polyethylene to the versatile charisma of polypropylene, and the clear allure of polystyrene, thermoplastics bring endless possibilities to create intricate designs with flair.

Standing steadfast alongside their thermoplastic counterparts, thermosetting polymers boast unique strength and permanence. These materials undergo a transformative chemical change when heated, rendering them impervious to re-melting or reshaping. Often chosen for their heat resistance and dimensional stability, thermosetting polymers, like epoxy, phenolic, and melamine, shine when durability and resilience are paramount.

Mastering the Art: The Advantages of Plastic Injection Molding

Embracing the limelight, injection molding emerges as a preeminent maestro in the realm of manufacturing, adorned with a symphony of advantages that set it apart from other techniques. The grand performance showcases its brilliance in delivering uniformity, cost-effectiveness, swift high-volume production, and a sustainable touch through recyclability.

Uniformity: A Harmonious Melody

In the realm of precision, plastic injection molding orchestrates an enchanting melody of uniformity. Each part is born from the same mold, a testament to consistent dimensions and features, even amidst complex geometries. This symmetrical grace ensures flawless products, resonating with industries that demand exactitude.

Cost-Effectiveness: A Thrifty Overture

The overture of cost-effectiveness strikes a chord with plastic injection molding. As the production crescendos, the cost per part diminishes gracefully. With minimal labor and time expenses after initial setup, this technique enchants businesses with its prudent approach, inspiring grand productions at a fraction of the cost.

Swift High-Volume Production: A Flourishing Symphony

The symphony of swift high-volume production echoes the magic of plastic injection molding. Casting a spell on the stage, it delivers parts in rapid succession, ideal for the mass production of identical companions. Time-sensitive demands are met, and markets are flooded with virtuoso creations, crafted with agility and grace.

Plastic injection molding is Recyclable: A Sustainable Sonata

As the performance reaches a crescendo, sustainability takes the spotlight. Plastic injection molding embraces recyclability, a harmonious sonata that reduces waste and treads lightly on the planet(Recyclable Injection Molding Materials). With the ability to recycle scrap materials, this virtuous process champions eco-consciousness, conducting a greener world.

Plastic Injection Molding: A Symphony of Applications

Injection molding’s versatility conducts an orchestra of applications, showcasing its artistic prowess in crafting an array of products, from automotive components to toys, packaging, and consumer goods. Each act of this manufacturing symphony unveils products that harmonize form, function, and precision.

Automotive Marvels

Within the automotive domain, injection molding plays a leading role, sculpting essential parts with finesse. Bumpers, dashboards, and interior trim take shape in durable thermoplastic materials, combining impact resistance and aesthetics, creating an ensemble of durability and style.

Toys: Joyful Crescendo

Embracing the realm of play, plastic injection molding orchestrates an enchanting repertoire of toys. From vibrant action figures to versatile building blocks, the performance celebrates safety and creativity, delighting the young and kindling imagination.

Packaging Panache

The packaging industry finds its cadence with plastic injection molding, as it produces sleek containers, secure caps, and closures. Lightweight and recyclable thermoplastic materials elevate packaging aesthetics, harmonizing with eco-consciousness.

Consumer Goods: A Harmonious Ensemble

The symphony continues with an array of consumer goods that enrich daily life. From kitchenware to electronics casings, plastic injection molding crafts functional products that blend seamlessly into modern living.

Mold Design: The Foundation of Excellence in Plastic Injection Molding

The significance of mold design in the plastic injection molding process cannot be overstated. It serves as the foundational element that profoundly influences the quality, dimensions, and performance of the final product. A meticulously crafted mold ensures the smooth flow of molten plastic, minimizes defects, and enhances the structural integrity of the produced parts. With its pivotal role in shaping the product’s form, mold design and mold flow analysis stands as the key to achieving consistency, intricate detailing, and overall excellence in the result.

Conclusion of Plastic Injection Molding

Throughout this exploration, plastic injection molding has dazzled with its versatility, shaping automotive components, playful toys, sophisticated packaging, and consumer goods with utmost precision. As a fundamental pillar in modern manufacturing, this transformative process has conducted a symphony of products that redefine aesthetics, functionality, and sustainability across diverse industries. Its enduring significance as an artistic marvel continues to elevate the standards of production, leaving an indelible mark on the world of manufacturing.

Besides from injection molding, TEAM Rapid also offers rapid prototyping, die casting, and 3d printing to meet your project needs. Contact our team today to request a free quote now!