Pressure Die Casting Services at Any Volume, Global Delivery

At TEAM RAPID we specialize in high-precision pressure die casting services, designed to meet the needs of manufacturers across North America and Europe. With a full spectrum of capability—from aluminum and zinc alloys to finished, ready-to-assemble components—we help you scale from prototypes to high-volume production with speed and efficiency.

What We Offer

- Comprehensive pressure die casting from tooling to finished part, based on decades of industry experience

-

Aluminum die casting: lightweight, high strength, excellent conductivity and corrosion resistance — suited for automotive, aerospace, LED lighting and beyond

-

Zinc die casting: excellent surface finish, high ductility and impact resistance — ideal when aesthetics and fine detail matter

-

Global supply chain and logistics support, ensuring delivery from Asia to the US/European markets without bottlenecks

-

Options for low-volume runs as well as full mass production, giving you flexibility at every stage of your product lifecycle

What Is Pressure Die Casting

Pressure die casting is an advanced metal manufacturing process that uses high pressure to inject molten metal into a precisely machined steel mold, known as a die. The result is a high-strength, dimensionally accurate metal part with an excellent surface finish and repeatable consistency. This process is ideal for mass production of aluminum, zinc, and magnesium components used across the automotive, electronics, aerospace, and industrial sectors.

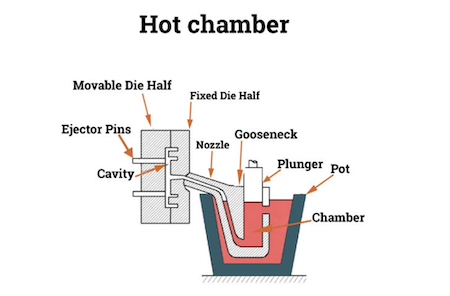

Depending on the type of metal, production speed, and required part quality, there are two main types of pressure die casting processes—hot chamber and cold chamber die casting. Each method offers distinct advantages, making it suitable for different alloys, applications, and performance requirements.

1. Hot Chamber Die Casting

Hot chamber die casting is the most common process for casting low-melting-point metals, such as zinc, magnesium, and certain lead-based alloys. In this process, the injection system (gooseneck) is submerged in the molten metal, allowing the metal to be injected directly into the die cavity quickly and efficiently.

How It Works

How It Works

-

The molten metal is held in an integrated furnace attached to the machine.

-

A piston forces the metal through the gooseneck and nozzle into the die cavity.

-

The molten metal solidifies under pressure, forming a precise, durable part.

-

The die opens, and ejector pins release the finished casting.

Advantages

-

Fast cycle times:Shorter casting cycles (2–5 seconds) enable high production rates.

-

Excellent surface quality:Produces smooth surfaces suitable for plating or painting.

-

Long tool life:Lower temperatures reduce wear on the die and injection components.

-

Cost-effective:Ideal for small-to-medium parts in large quantities.

Common Alloys

-

Zinc (Zamak 3, Zamak 5)

-

Magnesium (AZ91D)

-

Lead and tin alloys

Typical Applications

-

Electrical components

-

Decorative fittings

-

Automotive interior parts

-

Precision connectors and enclosures

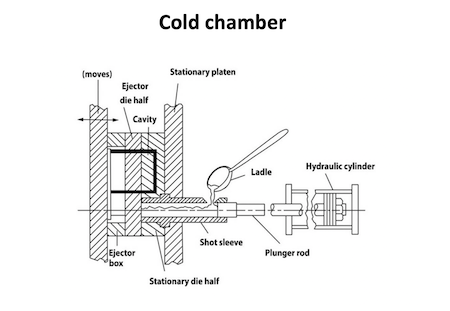

2. Cold Chamber Die Casting

Cold chamber die casting is used for high-melting-point metals such as aluminum, copper, and magnesium alloys that would otherwise damage a submerged injection system. In this process, the molten metal is poured into a separate shot chamber before being injected into the die under high pressure.

How It Works

How It Works

-

Molten metal is ladled into the shot chamber from an external furnace.

-

A hydraulic piston injects the metal into the steel die at high pressure (typically 10,000–25,000 psi).

-

The metal rapidly cools and solidifies within the mold.

-

The die opens, and the solidified casting is ejected for trimming and finishing.

Advantages

-

Handles high-melting-point alloys:Ideal for aluminum and copper components.

-

Strong and durable parts:Excellent mechanical properties and dimensional accuracy.

-

Corrosion-resistant results:Aluminum and magnesium alloys are lightweight and strong.

-

Flexible production:Suitable for both low and high-volume manufacturing.

Common Alloys

-

Aluminum (A380, ADC12, A360)

-

Copper and brass

-

Magnesium (AM60B, AZ91)

Typical Applications

-

Automotive engine and transmission housings

-

Aerospace components

-

Heat sinks and lighting housings

-

Structural brackets and enclosures

Choosing the Right Type of Pressure Die Casting

The choice between hot chamber and cold chamber die casting depends on factors such as:

| Factor | Hot Chamber | Cold Chamber |

|---|---|---|

| Melting Point of Alloy | Low (zinc, magnesium) | High (aluminum, copper) |

| Cycle Time | Shorter | Longer |

| Part Strength | Moderate | High |

| Tool Life | Longer | Shorter due to higher temperature |

| Application | Small intricate parts | Large structural components |

Selecting the right process ensures optimal part quality, production efficiency, and cost-effectiveness.

Why High Pressure Die Casting in China

Choosing high pressure die casting (HPDC) in China gives manufacturers around the world access to advanced technology, skilled engineering talent, and highly competitive production costs. Over the last two decades, China has become a global hub for high pressure die casting, delivering millions of precision-engineered aluminum and zinc components to customers across industries such as automotive, aerospace, medical devices, and electronics.

1. Advanced Manufacturing Capabilities

China’s die casting industry has made huge progress in both technology and quality control. Modern factories now operate with fully automated HPDC machines ranging from 250 to 6,000 tons, capable of producing small intricate components to large structural castings for electric vehicles.

Key technological advantages include:

-

Vacuum die casting systems for low porosity and improved mechanical properties.

-

Robotic automation for injection, trimming, and part handling.

-

Computer-aided mold design and simulation software(CAD/CAE) for improved accuracy.

-

CNC machining centers for precision finishing and tight tolerance control.

These advancements allow Chinese suppliers to produce high-performance, lightweight, and complex metal parts that meet international standards.

2. Cost Efficiency and Scalability

One of the biggest reasons global companies choose HPDC in China is cost efficiency. With optimized production lines, lower labor costs, and integrated supply chains, Chinese foundries offer significant savings compared to Western suppliers — without sacrificing quality.

In addition, China provides flexibility across all production volumes:

-

Low-volume die casting for prototypes and pilot runs.

-

Mass production for global OEM and Tier-1 suppliers.

-

Tooling and mold production in-house to reduce lead time and cost.

This scalability makes China ideal for companies seeking both speed and cost control.

3. Strong Supply Chain and Material Availability

China has developed one of the world’s most complete metal manufacturing ecosystems, with easy access to raw materials such as aluminum, zinc, and magnesium alloys. Foundries work closely with local toolmakers, surface finishing specialists, and logistics providers, forming a seamless production network.

This integrated supply chain ensures:

-

Shorter lead times from tooling to final delivery.

-

Consistent material quality through standardized alloy grades (e.g., ADC12, A380).

-

Efficient global shipping via established export channels to the USA and Europe.

4. High Quality and International Standards

Modern Chinese die casting companies follow strict quality assurance systems such as ISO 9001, IATF 16949, and ISO 14001. Many plants are equipped withCMM inspection,X-ray flaw detection, and pressure testing equipment to ensure every part meets the design and performance requirements. Continuous quality monitoring throughout the production process allows Chinese HPDC suppliers to meet the expectations of automotive, aerospace, and industrial clients worldwide.

5. Innovation and Lightweight Design Leadership

Driven by the electric vehicle (EV)and green energy industries, Chinese die casting factories are investing heavily in lightweight design and mega casting technologies. These allow production of large, one-piece aluminum components — such as EV chassis and battery housings — that reduce vehicle weight and improve energy efficiency. By adopting AI-based process control, smart data monitoring, and recycled aluminum alloys, China’s HPDC industry is moving toward sustainable and intelligent manufacturing, making it an ideal long-term partner for international customers.

6. Partnering with TEAM RAPID

As one of the leading high pressure die casting suppliers in China,TEAM RAPID provides complete one-stop solutions— from tool design and rapid prototyping toCNC finishing and assembly. We work closely with clients in the USA and Europe to deliver custom aluminum and zinc die cast parts that meet tight deadlines, strict tolerances, and global quality standards.

Our strengths include:

-

Skilled engineering team with decades of HPDC experience

-

In-house tooling and rapid prototyping development

-

Strong quality control and inspection system

-

Fast lead times and cost-effective solutions for global clients

Whether you’re launching a new product or scaling up production, TEAM RAPID helps you transform your ideas into precision metal components with unmatched speed, reliability, and value.

High Pressure Die Casting Capabilities at TEAM RAPID

At TEAM RAPID, we specialize in both hot chamber and cold chamber high pressure die casting for aluminum and zinc alloys. With advanced equipment, in-house tooling, and precision machining, we deliver high-quality parts that meet international standards. See our capabilities below:

|

Died Casting Mold |

Died Casted Parts |

Post Machining |

Surface Finishes |

||||

| Mold Material: | H13; SKD61; | Part Material: |

1. ADC10; ADC12; A360; A380; A413; A356; LM20; LM24 2. Zinc alloy 3#, 5#, 8# |

Machining Capability: | 3 axis/4 axis/5 axis CNC Machines |

Polishing; Sand blasting; Powder Coating; e-coating; Plating; Anodizing; Painting; Galvanized |

|

| Cavity: | Single or Multiple | Casting Tolerance: | IT4 to IT6 | Machining Process: | CNC Milling; CNC Turning; CNC Taping | ||

| Mold Lifetime: | 50K Shots | Unit Weight: | 5g to 10KG | Machining Tolerance: | +/-0.005 to 0.001mm; ISO 2768f | ||

| Mold Lead Time: | 2 to 4+ weeks | Dimension: | <=1200mm | Dimension: | <=1100mm | ||

| Small order is accepted; Weekly report; Full inspection before shipment; After sales services | |||||||

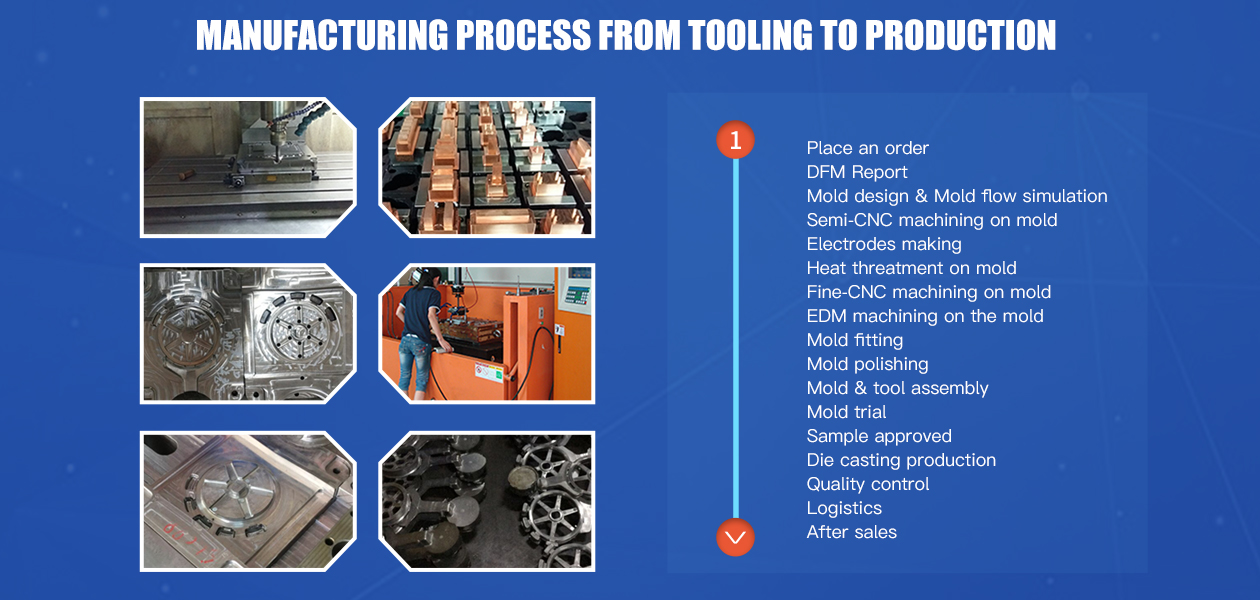

Working Flows from Ordering to Delivery:

Aluminum Die Casting

Aluminum die casting is one of the most efficient and precise metal manufacturing processes used today. It involves forcing molten aluminum alloy into a hardened steel mold under high pressure to produce strong, lightweight, and dimensionally accurate components. This method allows manufacturers to create parts with complex shapes, thin walls, and excellent surface finishes — ideal for both functional and aesthetic applications.

Aluminum die casting is one of the most efficient and precise metal manufacturing processes used today. It involves forcing molten aluminum alloy into a hardened steel mold under high pressure to produce strong, lightweight, and dimensionally accurate components. This method allows manufacturers to create parts with complex shapes, thin walls, and excellent surface finishes — ideal for both functional and aesthetic applications.

Why Choose Aluminum Die Casting

Aluminum is one of the most popular materials for die casting because it offers an outstanding balance of strength, weight, and performance.

-

Lightweight and durable:Aluminum parts are up to 70% lighter than steel while maintaining excellent mechanical strength.

-

Corrosion and heat resistant:Perfect for outdoor and high-temperature environments.

-

Excellent conductivity:Ideal for electronic housings and heat dissipation applications.

-

Smooth finish and complex geometry:Enables high-precision parts with fine details and minimal machining.

Zinc Die Casting

Zinc die casting is a highly efficient manufacturing process used to produce precise, durable, and complex metal components. During production, molten zinc alloy is injected into a steel mold under high pressure, forming parts with excellent strength, dimensional accuracy, and superior surface finishes.

Zinc die casting is a highly efficient manufacturing process used to produce precise, durable, and complex metal components. During production, molten zinc alloy is injected into a steel mold under high pressure, forming parts with excellent strength, dimensional accuracy, and superior surface finishes.

Why Choose Zinc Die Casting

Zinc alloys are well-known for their excellent castability, toughness, and long tool life. Compared to other metals, zinc offers a unique combination of mechanical and economic advantages:

-

High strength and hardness:Zinc die casting parts deliver superior impact resistance and wear properties.

-

Exceptional fluidity:Perfect for thin-wall or detailed parts that require intricate features and tight tolerances.

-

Longer mold life:The low melting temperature of zinc reduces tool wear, resulting in lower tooling costs and longer production runs.

-

Smooth and aesthetic finish:Zinc parts can be easily plated, painted, or powder-coated for decorative and functional purposes.

-

Fast and cost-effective production:Shorter cycle times make zinc die casting ideal for high-volume manufacturing with consistent quality.

Advantages of High Pressure Die Casting

High Pressure Die Casting (HPDC) is one of the most efficient and precise manufacturing processes for producing complex metal parts in large volumes. It offers numerous advantages that make it a preferred choice for industries such as automotive, aerospace, electronics, and consumer products.

1. Excellent Dimensional Accuracy and Surface Finish

High pressure die casting allows molten metal to be injected into steel molds at very high pressure. This results in parts with tight tolerances, smooth surfaces, and excellent repeatability, minimizing the need for post-machining or finishing operations.

2. High Production Efficiency

Once the die is made, the process cycle is extremely fast—typically just seconds per part. This makes HPDC ideal for mass production of components, significantly reducing unit costs and ensuring consistent quality across thousands of parts.

3. Complex and Thin-Walled Designs

The high injection pressure allows metal to flow into intricate mold details and thin sections that other casting methods cannot fill. This means HPDC can produce lightweight, complex, and detailed parts with integrated features such as threads, ribs, and bosses, reducing the need for assembly.

4. Superior Mechanical Strength

Because molten metal solidifies quickly under pressure, the resulting parts are dense and strong, with good mechanical properties and high structural integrity. This is essential for components that need to withstand stress, impact, or heat.

5. Material and Cost Savings

High pressure die casting minimizes material waste. Since most parts are near-net shape, less machining and scrap occur, and leftover material can often be recycled and reused, making the process cost-effective and sustainable.

6. Versatility in Metals and Applications

HPDC can be used with a range of alloys, including aluminum, zinc, and magnesium, each offering specific advantages for different applications. This flexibility allows engineers to balance weight, strength, and cost depending on product requirements.

7. Consistency and Automation

Modern HPDC machines are fully automated, ensuring consistent part quality, precise process control, and low labor costs. Automation also improves safety and reduces human error during production.

High Pressure Die Casting vs. Low Pressure Die Casting

Both High Pressure Die Casting (HPDC) and Low Pressure Die Casting (LPDC) are popular methods for producing aluminum and other alloy parts. The key difference lies in how molten metal fills the die cavity.

Process Difference

-

HPDC:Metal is injected into the mold under high pressure (10–175 MPa)for fast, precise, and high-volume production.

-

LPDC:Metal is pushed upward into the mold underlow gas pressure (0.3–1.5 bar), allowing smoother filling and less turbulence.

Main Comparison

| Feature | HPDC | LPDC |

|---|---|---|

| Injection Pressure | High | Low |

| Cycle Time | Short (seconds) | Long (minutes) |

| Porosity | Higher | Lower |

| Surface Finish | Excellent | Good |

| Heat Treatable | No | Yes |

| Production Volume | High | Medium |

| Applications | Housings, brackets, engine parts | Wheels, suspension parts, structural components |

- High Pressure Die Casting is ideal for high-speed, medium to high volume production of detailed parts with great surface quality.

- Low Pressure Die Casting suits structural parts requiring higher strength and lower porosity.

Both offer reliable, efficient solutions depending on project needs and material performance.

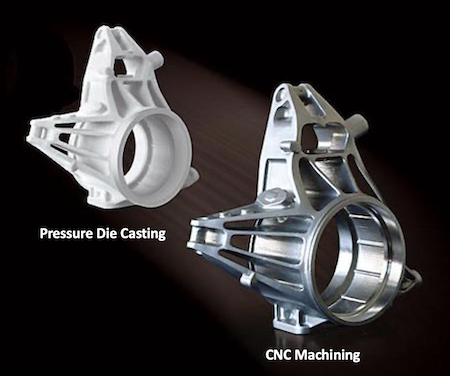

High Pressure Die Casting vs. CNC Machining

When developing precision metal parts, High Pressure Die Casting (HPDC) and CNC Machining are two of the most popular manufacturing methods. Both can produce high-quality components, but they differ greatly in process, cost, and ideal applications. Understanding the strengths of each helps you make the best choice for your project.

Key Differences Between HPDC and CNC Machining

| Feature | High Pressure Die Casting | CNC Machining |

|---|---|---|

| Production Volume | Best for medium to high production volumes where tooling cost is justified. | Ideal for low to medium runs or when design changes are frequent. |

| Material Waste | Minimal waste; near-net-shape parts reduce machining needs. | More waste due to material removal from a solid block. |

| Tooling Investment | Requires expensive dies and longer lead time for tooling. | Minimal tooling cost; quick setup and design flexibility. |

| Surface Finish | Naturally smooth and suitable for polishing or coating. | Excellent finish, especially for precision surfaces. |

| Dimensional Accuracy | Very good accuracy with consistent repeatability. | Exceptional precision and tight tolerances achievable. |

| Design Changes | Harder to modify after the mold is made. | Easy to update by changing the machining program. |

| Lead Time | Longer at the start due to mold manufacturing. | Shorter for prototypes and initial batches. |

Combining Both Processes

In many cases, the most efficient approach is a combination of both methods.

In many cases, the most efficient approach is a combination of both methods.

A common strategy is to use die casting to produce the base shape and thenCNC machining to refine critical surfaces, threads, or assembly features.

This hybrid solution offers the best of both worlds:

-

High production efficiency from HPDC.

-

Tight tolerance and accuracy from CNC machining.

TEAM RAPID often applies this approach for automotive housings, lighting components, and structural brackets— achieving both performance and cost advantages.

Suggestions

BothHigh Pressure Die Casting and CNC Machining have unique benefits.

-

HPDC offers speed and cost efficiency for large-scale production.

-

CNC Machining delivers precision and flexibility for smaller batches or evolving designs.

At TEAM RAPID Manufacturing Co., Ltd, we provide complete solutions from die design, tooling, and casting to CNC finishing, inspection, and global shipping. Whether your project targets the USA or European markets, we help you bring your product to market faster with reliable quality and competitive cost.

See Our OEM Die Casting Models and Projects

Our project managers at TEAM Rapid work with a range of product developers, product designers, entrepreneurs, and engineers worldwide to help them make high-quality die casting models and products. Please look at examples of pressure die casting projects we've worked on and see how they were made. And some other projects in different processes:

Lounge Chair Fame - Case Study

Electric Kettle Base - Case Study

Cooling Conditioner Fan Back Cover - Case Study

Our customers come from different industries. Here we have a statistic that most of our projects are for the 7 sectors below:

1. Automotive Die Casting Parts

Automotive manufacturers rely heavily on high pressure die casting for components that must be both strong and lightweight.

Typical aluminum die cast parts used in vehicles include:

-

Engine blocks and cylinder heads

-

Transmission and gearbox housings

-

Oil pump and clutch covers

-

Engine brackets and mounts

-

Electric vehicle (EV) battery enclosures

-

Steering and suspension components

-

Brake calipers and master cylinder housings

-

Alternator and starter motor housings

Why use HPDC for automotive parts?

Die casting ensures consistent quality, excellent dimensional accuracy, and reduced vehicle weight — helping automakers improve fuel efficiency and performance.

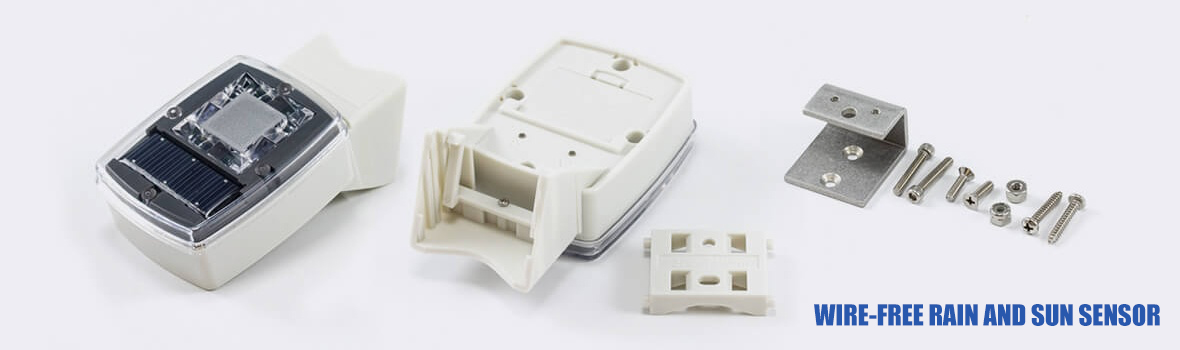

2. Electronic and Electrical Housings

Aluminum and zinc die casting is widely used for electrical housing sand heat-dissipating components.

Common parts include:

-

LED lighting housings and heat sinks

-

Motor and generator casings

-

Electrical junction boxes

-

Sensor enclosures and connector shells

-

Smartphone and laptop frames

-

Power supply covers and cooling bases

Why use HPDC for electronics?

The process offers great heat conductivity, EMI shielding, and smooth surfaces for powder coating or anodizing — perfect for precision electronic applications.

3. Industrial Machinery Components

High pressure die cast components provide strength and durability for industrial and mechanical systems.

Typical parts include:

-

Hydraulic and pneumatic valve housings

-

Gear housings and gearboxes

-

Compressor end covers

-

Pump and bearing housings

-

Machine tool frames and covers

Why use HPDC for machinery?

Die casting offers near-net-shape accuracy, minimizing machining and improving production efficiency for heavy-duty parts.

4. Aerospace and Defense Components

Aerospace and defense industries use HPDC to create lightweight but strong parts that can withstand demanding conditions.

Examples include:

-

Drone frames and motor housings

-

Avionics enclosures and radar covers

-

Structural brackets and supports

-

Aircraft seat and cabin fittings

Why use HPDC for aerospace?

It reduces component weight without sacrificing strength, helping improve fuel economy and system performance.

5. Consumer and Lifestyle Products

From home appliances to power tools, die cast aluminum parts give a premium look and long-lasting durability.

Examples include:

-

Power tool housings (drills, grinders, saws)

-

Kitchen appliance bodies (blenders, mixers)

-

Furniture handles and hardware

-

Camera housings and lighting components

-

Bicycle and scooter frames

Why use HPDC for consumer products?

It allows stylish, complex designs with smooth surfaces and strong structural integrity — ideal for modern consumer goods.

6. Telecommunication Equipment

High pressure die casting is perfect for telecommunication and 5G hardware requiring strength and heat dissipation.

Typical parts include:

-

Antenna brackets and housings

-

Base station components

-

Signal amplifier enclosures

-

Satellite receiver bodies

Why use HPDC for telecom parts?

Aluminum die cast housings protect sensitive electronics while providing excellent thermal management and EMI shielding.

7. Medical and Healthcare Devices

Precision die cast components are also used in medical devices where cleanliness, precision, and reliability are vital.

Common parts include:

-

Imaging system covers

-

Portable diagnostic device housings

-

Cooling plates for lasers or electronics

-

Medical instrument handles and frames

Why use HPDC for medical parts?

HPDC offers biocompatible surfaces, high strength, and repeatable quality essential for safe and reliable medical equipment.

Moving Forward from Rapid Prototyping to Volume Production

At TEAM RAPID, we understand that every great product starts with an idea — and turning that idea into a successful product requires the right manufacturing approach at every stage. We provide a complete metal manufacturing solution, starting from rapid prototyping to low-volume and mass production, using the best-fit technologies like CNC machining and High Pressure Die Casting (HPDC).

From Prototype to Production – One Partner, Full Support

From Prototype to Production – One Partner, Full Support

When you are developing new metal parts, the first step is to test your concept. TEAM RAPID offers rapid prototyping services to help you evaluate your design quickly and cost-effectively. Our CNC machining and 3D printing capabilities allow you to create accurate prototypes in aluminum, zinc, or magnesium alloys. These prototypes help verify part design, assembly fit, and performance before investing in production tooling. Once the prototype is confirmed, we help you move forward smoothly to production— whether you need a few hundred parts or hundreds of thousands.

Low-Volume Production with CNC Machining

For small to medium quantities, CNC machining is the ideal solution.

It offers flexibility, high precision, and fast turnaround for:

-

Functional prototypes

-

Engineering test parts

-

Pilot runs and bridge production

With our3-, 4-, and 5-axis CNC machining centers, we can produce complex geometries and tight-tolerance metal components without expensive molds or dies. This allows you to bring your product to market faster and adjust your design when needed.

Scalable Manufacturing with High Pressure Die Casting

When your project reaches higher production demand, High Pressure Die Casting becomes the most cost-effective solution.

We design and manufacture custom die casting mold sin-house to produce metal parts with:

-

Excellent dimensional accuracy

-

Smooth surface finish

-

High strength and repeatability

HPDC is perfect for medium to high-volume production of aluminum and zinc alloy components used in the automotive, electronics, and industrial sectors.

To ensure quality, we also provide:

-

CNC machining after casting for precision features

-

Surface finishing such as polishing, anodizing, and powder coating

-

Strict inspection and testing before delivery

With HPDC, we help you reduce unit cost, improve efficiency, and achieve consistent part quality across every batch.

One-Stop Metal Manufacturing Solution

From prototype to mass production, TEAM RAPID is your single manufacturing partner for every stage of product development.

Our services include:

-

Rapid Prototyping (CNC, 3D Printing, Vacuum Casting)

-

Low-Volume Production (CNC Machining, Soft Tooling)

-

Medium to High-Volume Production (High Pressure Die Casting)

-

Post-Machining, Surface Treatment, and Assembly

-

Quality Inspection and Global Shipping

We help customers all over the world to shorten lead times, lower production costs, and bring high-quality metal products to market faster.

Making Your Plastic Parts and Metal Parts Under One Roof

As a leading contract manufacturer, TEAM RAPID provides end-to-end solutions for both metal die casting and plastic parts fabrication. We specialize in helping customers turn design ideas into high-quality, production-ready parts quickly and efficiently. With our rich engineering experience and advanced manufacturing facilities, we can handle every stage — from rapid prototyping and tooling development to low- and high-volume production.

Our expert engineers understand your design intent and offer multiple production proposals to achieve the best balance between quality, cost, and lead time. As a professional die casting contract manufacturer, we know how to optimize both metal and plastic components to ensure perfect assembly and outstanding performance.

Partnering with TEAM RAPID means working with a reliable contract manufacturing partner who is dedicated to delivering precision, speed, and value — helping you reduce investment costs and bring your products to market faster. Request a Free Quote Now!

Frequently Asked Questions

What is Die Casting and Its Types?

Commonly referred to as die casting, this process involves forcing molten metal into a mold known as "Dies," which then hardens into a metal casting. This process is commonly used to manufacture various components, such as toys and automotive housings.

The process involves adding various chemical elements to the molten metal to create a desired metal composition. Besides aluminum, copper, lead, magnesium, and zinc are also widely used to produce complex components.

Die Casting Types

Hot chamber and cold chamber machines are the two main types of die-casting equipment. There are varying variations in these two processes, such as squeeze, vacuum, semi-solid, and low-pressure. The die-casting process's complexity, part material, geometry, and size are also considered when choosing a method.

What is Die Casting Process?

Die casting is a metal manufacturing process. The die-casting process involves forcing molten metal into a mold cavity at high pressure. The mold cavity is made using two hardened steel dies that have been turned into shape using a process known as machining. Most die castings are made out of non-ferrous metals such as copper, aluminum, magnesium, lead, and zinc. Depending on the type and quantity of metal being cast, either a cold-chamber or hot-chamber machine is utilized.

Due to the large capital costs associated with the equipment and dies used in the process, it tends to limit the amount of production that can be done. Die casting is a simple process used to manufacture various parts. It is ideal for small to medium-sized castings and is very good at producing high-quality components. Compared to other processes, die casting is more productive and produces more castings. It is characterized by a good surface finish and dimensional consistency.

The standard die-casting process can be done in either a cold or hot chamber. The steps involved in this process are explained below.

1. Clamping

The first step in the die casting process is to clean the die. After that, it's important to perform a lubrication and cleaning procedure to remove any impurities. Then, close the die using high pressure.

2. Injection

You can inject the metal you want into the shot chamber using melted metal. Depending on your process, the injection may take place differently. The shot chamber can be cold or hot in different die casting processes. After that, the metal can be injected into the die using a hydraulic system.

3. Cooling

After cooling down, the metal can be solidified. This process can create a mold-like shape.

4. Ejection

An ejection mechanism will push the solid part out of the die mold after unclamping it. Prior to this, ensure proper solidification.

5. Trimming

The last step in the die casting process is removing the excess metal in the finished product. This can be done through a variety of methods, such as trimming. The metal parts that are removed can be reused or recycled. Trim can be achieved using various methods, such as saw cuts, die trimming, and other procedures. The metal parts taken out are reusable and recyclable.