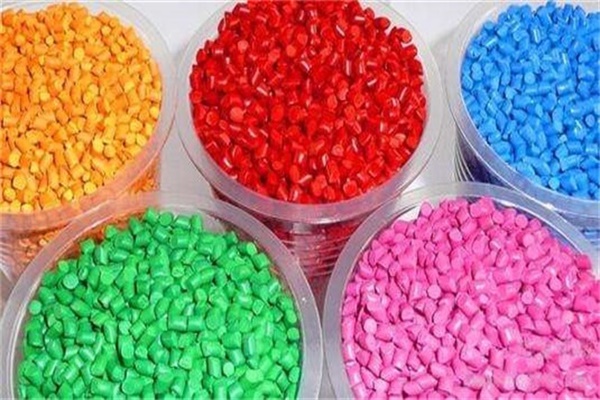

To select plastic resin material for your injection molding project is an important topic. Before having a final decision, to answer the questions below will help guide you to the right choice.

Table of Contents

1. What is your product’s intended end use?It affects on what plastic resin you need.

Does the product need to have flexibility or rigidity?

Does the product works under pressure or weight?

Will the product works in harsh conditions?

Will the product be exposed to chemicals or other elements?

2. Does the product need special appearance?It affects on what plastic resin you need.

Is it needs particular finish?

Does it have high level color matched?

Is embossing a consideration?

3. What, if any, regulatory requirements apply?

Must your product need to meet ROHS standards?

Will the product contact with food and need to be food safe?

Will the product reached and used by children?

The questions above are the topic we need to think about before starting injection molding. Different material always leads to different performances. We need do a further study and select the best plastic resin to meet your needs.

Contact TEAM Rapid

TEAM Rapid is a professional rapid tooling and Injection Molding Company in China. Dupoint, Bayer, BASF, Sabic as well as lots of material agents are our long-term partners that we have cooperated with, we can provide a material COC (Certificate of Conformity) as well as a RoHS report to show proof and guarantee that real resin is used. Send us an email at [email protected] today and get a free quote.