Prototype molds are also called soft mold, test mold, development mold, pre-production mold, short run production mold. It is very helpful in new product development as it can lower the cost of tooling cost and speed up the development process. Prototype molds also can test the molding process, production molding materials. By using prototype molds, manufacturers can find the errors at the early stage which significantly save time and money. It is a bride to connect small and large volume production.

As there are many different type of prototype mold, choosing the appropriate one is difficult. But knowing the materials and design that are going to be developed is quite helpful as every type of prototype mold has its advantages and disadvantages.

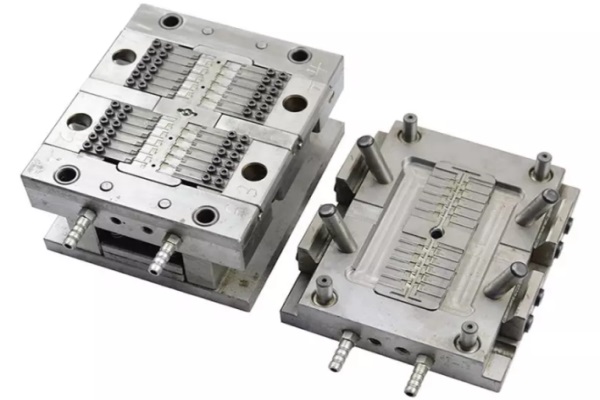

Master Unit Die molds. It consists of mold insert and mold base. Mold makers have their own mold base and build the insert by using CNC, EDM and wire cut according to the design which helps to lower customers’ early injection mold cost and keep the part quality and unit cost.

Hand tooling is the most cost-effective way of injection molding parts. Production of parts needs worker hand putting the insert into the mold then de-mold parts when the injection process is finished. If mold makers make it to be a 100% automatic mold, they have to make it as thread mold which increase the mold cost a lot. If part order is small, mold makers can use thread as a insert, put the insert into the mold for molding, and hand-demold the insert.

Before considering the steel prototype mold, manufacturers need to check part design, tooling structure and production issues. It is more easier to build a aluminum Mold Tooling than a steel prototype mold.

With prototype molds, manufacturers are able to test different type of plastic materials and check if the parts fill properly without any defects. Prototype mold is an ideal option for complex parts. It helps to speed up development and save production time. It helps to save the mold cost as well.

At TEAM Rapid, we always aim to offer customers the most cost-efficient solution to their prototyping project while providing with high quality parts. For more information about our prototyping capacity or any inquiry your may have, please contact us at [email protected] .