SLA rapid prototyping is one of the most common 3D printing technologies that can be used to create concept models rapid prototyping and additive manufacturing. It is the process of transferring the liquid plastic into the solid 3D parts through a stereolithograph apparatus, or SLA machine. SLA prototyping process is normally used in the early product development process. It create parts with high quality smooth surface finish, high accuracy and thin, straight, vertical walls.

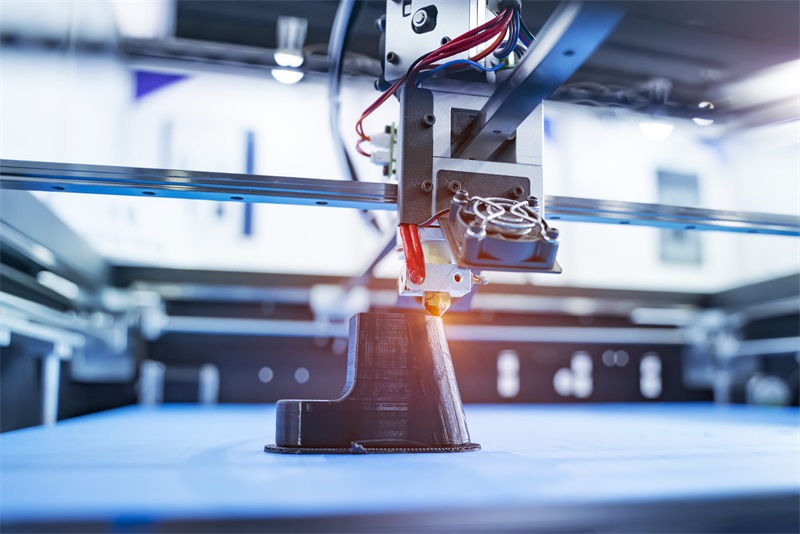

Stereolithography is an additive manufacturing process works focusing an UV laser on to a vat of photopolymer resin. With the help of CAM and CAD software, UV laser is used to draw a pre-programmed design. The resin is photochemically solidified and forms a layer of the 3D part. And then create platform lowers one layer. This process is repeated for every layer of the design until the 3D printing part is finished.

SLA is an ideal option for low volume production of prototype parts for concept models, presentation models or tooling masters which are needed very quickly and lower prices. SLA applications include concept models, presentation models, investment casting, master patterns.

SLA offers numerous advantages including high accuracy, smooth surface finish, fast turnaround, low cost with economic sale, heat and moisture resistance etc. SLA rapid prototyping is attractive because of its speed. Depending on the complexity of the parts, SLA rapid prototyping parts can be come out within hours or day. SLA Rapid Prototyping parts can be machined and made master pattern for injection molding or metal casting because they are strong enough.

The most commonly use liquid material used on SLA printing is resins and thermoset polymer. There are many types of resins available. Home-made resin is possible to test different compositions. Material properties depend on formulation configurations. Resins categories include standard resins, engineering resins, dental and medical resins and castable resins. Standard resin is used for general prototyping. Engineering resins is used for specific mechanical and thermal properties. Dental and medical resins are used for mechanical and thermal properties. Castable resin is used for zero ash-content after burnout.

At TEAM Rapid, we have the most advanced SLA project machines from 3D system that give us capacity to produce SLA parts fast and cost effectively. Any SLA rapid prototyping inquiry is welcomed. Contact us at [email protected] today!