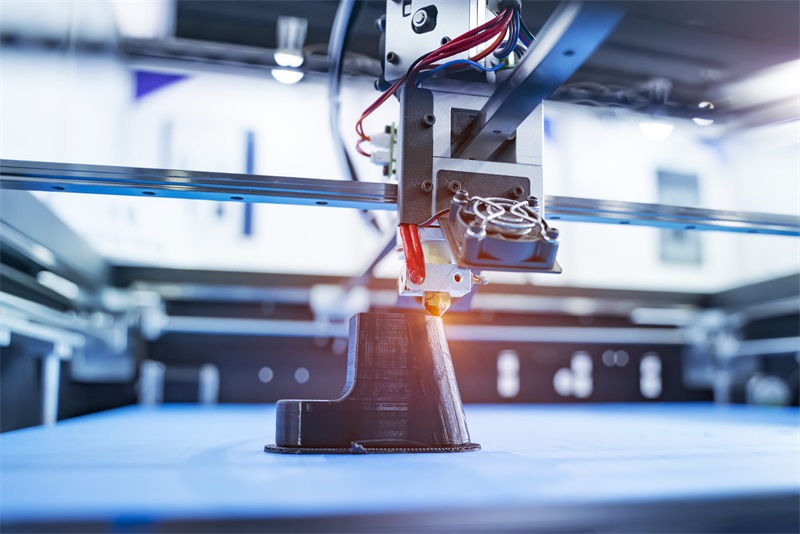

3D printing involves a wide range of prototyping techniques. Rapid prototyping is one of the main techniques used in 3D printing. It is a an effective budget friendly prototyping method. Rapid prototyping is a tool in the costly changes because of the unprecedented issues during full-scale production, SLA Rapid Prototyping Vs SLS Rapid Prototyping.

Stereolithography and selective laser sintering has become popular. They use lasers but their application processes are different. How are the two correlated and how do they work?

Stereolithography uses a special machine called the stereolithography apparatus that converts molten polymer into a solid 3D product. When coming up with structures with complicated geometries, concept models, primary patterns in urethane castings and one-off models, stereolithography machines are very useful. The stereolithography apparatus have an ultraviolet laser, a perforated platform, plastic liquid and a computer program which controls the platform. A layer of photopolymer covers the perforated platform to trace the cross-section of the printed parts. The liquid plastic is curable and hardens when exposed to UV, a new layer is formed. And the platform is lowered and a new layer of liquid plastic is exposed when hardening.

SLS is using thin layer of tiny particles like ceramic, plastic or glass which is fused by a high powered laser to form a solid part. SLS machines print 3D models of material like ceramics, plastics and even metals. SLS starts with a CAD format design. Materials are dispersed above the built platform inside the SLS machine. An infrared laser then laser fuses the particles together to form layer by layer geometries.

When to choose SLA and SLS, you need to consider some factors like resolution, appearance, abrasion resistant ability and mechanical resistant ability.

SLA machines resolve better products than SLS both vertically and horizontally. SLS part has microscopic air bubbles which cannot be seen by naked eye but touched, the surface feels rough. SLS prototypes behave under the circumstances of temperature, humidity and chemicals. SLA material has poor abrasion resistant ability compared to SLS material.

Every printing technique has its own advantages and disadvantages. If you want functionality, SLS prototyping is the way to go. If you want mechanical limitations, SLA is the ideal choice.

Contact us at [email protected] today to learn more about SLA Rapid Prototyping Vs SLS Rapid Prototyping!