Battery Holder: Design, Materials, and Manufacturing Methods Explained

A poorly designed battery holder doesn't just fail. Itcosts you. Loose connections, overheating, and cracked housings. These problems kill product timelines and drain budgets faster than the batteries themselves. Whether you're prototyping a new device or scaling to mass production, the holder is often an afterthought. That's a mistake.

This guide covers everything you need to get it right:

● What a battery holder is and why design matters

● Types of battery holders and their applications

● Materials for durability and performance

● How to make a custom battery holder

● Prototyping methods: 3D printing, CNC machining, vacuum casting

● Injection molding for volume production

● Surface finish options and final considerations

At TEAM Rapid, we help engineers and product teams move from prototype to production fast. CNC machining, 3D printing, and injection molding. We've done thousands of battery holder projects across industries.

What Is a Battery Holder?

A battery holder is a housing component designed to secure one or more batteries while establishing electrical contact with the device it powers. Think of it as the bridge between stored energy and functional electronics. Without it, batteries would just be loose cells with nowhere to go.

The holder does two jobs simultaneously. It keeps cells physically locked in placeand transmits power through metal contacts or spring terminals. Most are made from molded plastic, though metal versions exist for high-vibration or industrial environments.

Core Functions of a Battery Holder

|

Function |

What It Does |

|

Secure Retention |

Prevents movement, rattling, or disconnection during use |

|

Electrical Contact |

Connects battery terminals to the device's circuit |

|

Protection |

Shields against short circuits, leakage, and environmental damage |

|

Easy Replacement |

Allows quick battery swaps without soldering or rewiring |

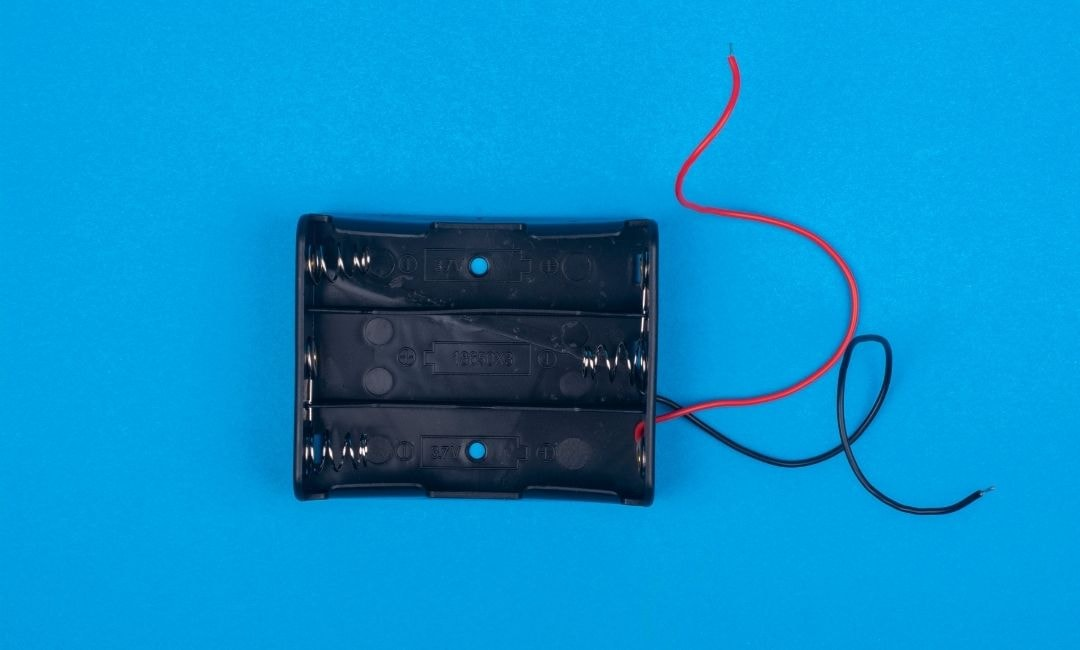

Key Components Inside a Battery Holder

Every battery holder bracket shares a few essential parts:

● Housing/Case: The plastic or metal body that shapes the compartment

● Contacts: Spring wires or flat metal tabs that touch the battery terminals

● External Connections: Pins, solder lugs, wire leads, or surface mount feet

● Lid or Cover: Optional component to protect against debris and accidental ejection

The contacts mattermost. Poorly designed contacts cause intermittent power, voltage drops, and device failure. High-quality holders use materials like nickel-plated steel or phosphor bronze to ensure conductivity and corrosion resistance.

Why It Matters for Product Design

A battery case holder isn't just a commodity part. It affects:

● User experience: How easy is it to swap batteries?

● Reliability: Will the device lose power under vibration or impact?

● Safety: Can it prevent reverse polarity or short circuits?

● Compliance: Does it meet product safety standards for your industry?

For custom electronics, off-the-shelf holders rarely fit perfectly. That's wherecustom battery holder solutions come in. TEAM Rapid works with engineers to prototype and manufacture holders tailored to specific dimensions, mounting requirements, and production volumes.

Pro Tip: If your product will undergo wave soldering or reflow soldering, standard polypropylene holders won't survive the heat. You'll need high-temperature materials like PBT, nylon, or LCP rated for 230°C+.

Types of Battery Holders

Not all battery holders are designed the same. The right type depends on your cell size, mounting method, and how the product will be used. Here's a breakdown of the most common configurations.

By Battery Size

|

Battery Type |

Common Uses |

Holder Style |

|

AA / AAA |

Remote controls, toys, flashlights |

Slide-in compartments, covered holders |

|

Coin Cell (CR2032, CR2025) |

Watches, IoT sensors, medical devices |

Low-profile PCB retainers, SMD holders |

|

18650 / 21700 |

Power tools, laptops, e-bikes |

Single-cell or multi-cell cylindrical holders |

|

9V |

Smoke detectors, guitar pedals |

Snap-on connectors |

|

C / D |

Industrial equipment, large flashlights |

Heavy-duty panel mount holders |

By Mount Type

● PCB Mount: Soldered directly onto a circuit board. Ideal for compact electronics where space is tight.

● Panel Mount: A removable compartment that snaps or screws into the device housing. Great for consumer products where users replace batteries frequently.

● Slide Mount: Batteries slide in and out horizontally. Cost-effective and reliable for standard applications.

● Snap Mount: Uses tensioned metal clips to lock the battery in place. Best for environments with shock and vibration.

● Wire Lead Mount: Features two wire leads for flexible integration into custom assemblies.

Single-Cell vs. Multi-Cell

Single-cell holders work for low-power applications. Multi-cell holders let you connect batteries inseries (higher voltage) orparallel (higher capacity). A four-cell AA holder in series delivers roughly 6V. The same cells in parallel would give you 1.5V with quadrupled capacity.

If your device will experience drops or movement, choose a holder with a lid or retention strap. Open-top designs risk battery ejection under impact.

Battery Holder Applications

Battery holders show up in nearly every industry. Their job is simple but critical: keep cells secure and power flowing. Here's where you'll find them.

Consumer Electronics

The largest segment by far. Think remote controls, wireless keyboards, handheld gaming devices, and LED flashlights. These applications demand compact, lightweight holders with easy battery access. Slide-in and covered panel-mount designs dominate here.

Medical Devices

Portable diagnostic tools, hearing aids, blood glucose monitors, and infusion pumps rely on battery holders for uninterrupted power. In this space, reliability isn't optional. Holders must meet strict safety certifications and resist corrosion from frequent handling.

Automotive

Key fobs, tire pressure monitors, and backup systems all use battery holders. Automotive-grade holders need to handle temperature extremes, vibration, and long service life without failure.

Industrial Equipment

Power tools, handheld scanners, and field instruments require rugged battery pack holders. Multi-cell configurations are common, and the holders must tolerate harsh operating conditions.

IoT and Wearables

Smartwatches, fitness trackers, and wireless sensors need ultra-compact coin cell holders. Space is at a premium, so low-profile SMD retainers are the go-to solution.

Renewable Energy

Battery holders play a role in solar-powered systems and off-grid energy storage. These setups often use cylindrical lithium-ion cells (18650 or 21700) arranged in custom packs.

Battery Holder Materials

The material you choose affects durability, heat resistance, and how well the holder survives manufacturing processes like soldering. Choose wrong, and you're looking at warped housings or failed connections.

Common Plastics for Battery Holders

|

Material |

Max Temp |

Best For |

|

Polypropylene (PP) |

80–100°C |

General-purpose holders, toys, and consumer electronics |

|

Nylon (PA66) |

80–120°C |

Housings requiring mechanical strength and wear resistance |

|

PBT (Glass-Filled) |

150–200°C |

High-temp applications, connectors, PCB-mounted holders |

|

LCP (Liquid Crystal Polymer) |

230–300°C |

Reflow soldering, lithium coin cell retainers |

|

ABS |

80–100°C |

Battery venting systems, covers requiring impact resistance |

Why Material Choice Matters

Most standard holders use polypropylene. It's cheap, chemically resistant, and works fine for handheld devices that never see extreme heat. But if your holder goes through wave or reflow soldering, polypropylenewill deform. You need PBT or LCP.

Glass-filled versions of nylon and PBT add rigidity and dimensional stability. This matters when tolerances are tight or when the holder must survive repeated battery swaps without cracking.

Contact Materials

The plastic body is only half the equation. Contacts make or break electrical performance.

● Nickel-Plated Steel: Standard choice. Prevents galvanic corrosion since most batteries are also nickel-plated.

● Phosphor Bronze: Better conductivity and spring memory. Used in high-reliability applications.

● Gold-Plated Contacts: Premium option for low-resistance connections in test equipment or medical devices.

If your battery holder will be exposed to moisture or outdoor conditions, insist on nickel-plated contacts. Corrosion on the contact surface is the number-one cause of intermittent power failures.

Design of Battery Holder

A good battery holder design goes beyond just "fitting the cell." It balances electrical performance, mechanical durability, user accessibility, and manufacturability. Get one of these wrong, and you'll face returns, redesigns, or worse.

Key Design Considerations

A few of the most important considerations for design are:

1. Contact Design

The contacts are everything. They must maintain a solid electrical connection through vibration, temperature changes, and repeated battery swaps.

● Spring contacts compress slightly to accommodate cell expansion during discharge

● Multi-finger contacts provide redundancy and maintain a connection even if the holder shifts

● Fixed + flexible combos offer a balance between cost and reliability

2. Polarity Protection

Reversed batteries cause short circuits. Simple design tricks can prevent this:

● Recessed anode contacts that only accept the battery's positive nub

● Plastic channels that guide the cell into the correct orientation

● Visual indicators (molded +/- symbols) to reduce user error

3. Ventilation

Batteries release small amounts of gas during discharge. Sealed holders trap this gas, which can lead to pressure buildup or even failure. If your product uses alkaline or zinc-air cells, design venting channels into the housing.

4. Human Factors

Think aboutwho will be changing the batteries:

● Is the product for children or elderly users? Avoid tight-fitting designs.

● Will users wear gloves? Consider larger openings and tactile guides.

● Is the holder visible, or buried inside a housing? Add orientation markers.

Tolerance and Fit

Battery dimensions vary slightly between manufacturers. A holder designed too tight will make insertion difficult. Too loose, and you risk intermittent connections.

|

Battery Type |

Nominal Diameter |

Recommended Cavity Tolerance |

|

AA |

14.5 mm |

+0.3 to +0.5 mm |

|

AAA |

10.5 mm |

+0.2 to +0.4 mm |

|

18650 |

18.6 mm |

+0.3 to +0.5 mm |

|

CR2032 |

20 mm |

+0.1 to +0.2 mm |

Always test your design with batteries from at least three different manufacturers. Dimensional variance is real.

How to Make a Battery Holder

Building a custom battery holder depends on your stage: early prototype, functional testing, or mass production. Each phase calls for different methods.

Prototyping Methods

Here are the most common methods of prototyping:

1. 3D Printed Battery Holder

This is the fastest way to validate a design. FDM printing works well for rough fit checks, while SLA delivers tighter tolerances and smoother surfaces.

● Pros: Cheap, fast, design freedom

● Cons: Limited material options, not suitable for high-heat environments

● Best for: Concept validation, form-fit testing

A 3D printed battery holder won't survive wave soldering or high-current applications, but itwill tell you if your dimensions are right before you commit to tooling.

2. CNC Machining Battery Holder

When you need functional prototypes in production-grade materials, CNC machining delivers. You can cut holders from polypropylene, nylon, ABS, or even aluminum for metal enclosures.

● Pros: Accurate, repeatable, real materials

● Cons: Higher cost per unit, limited to geometries that the tool can reach

● Best for: Functional testing, pre-production samples

3. Vacuum Casting

If you need 10 to 50 units in production-like plastic, vacuum casting bridges the gap between 3D printing and injection molding. A silicone mold is made from a master pattern, then filled with polyurethane resin.

● Pros: Low tooling cost, decent surface finish

● Cons: Molds wear out after 20-30 shots

● Best for: Small batch testing, investor samples

Production Methods

Injection Molding Battery Holder

For volume production, injection molding is the standard. Molten plastic is forced into a steel or aluminum mold, cooled, and ejected. Cycle times run from 15 to 60 seconds per part.

|

Volume |

Tooling Cost |

Unit Cost |

|

500-1,000 |

$2,000-$5,000 (aluminum) |

$0.50-$1.50 |

|

10,000+ |

$5,000-$15,000 (steel) |

$0.10-$0.40 |

Injection molding locks in your design. Changes to the mold are expensive, so validate thoroughly before committing.

Surface Finish for Battery Holders

Surface finish affects more than looks. It influences how easily batteries slide in, how well contacts grip, and whether the holder survives its operating environment.

Common Finish Options

|

Finish |

Description |

Use Case |

|

As-molded (SPI B2/B3) |

Semi-gloss, tool marks visible |

Standard consumer products |

|

Textured (MT or VDI) |

Matte, patterned surface |

Hide sink marks, improve grip |

|

Polished (SPI A1/A2) |

Mirror-like, smooth |

High-end electronics, medical devices |

|

Bead blasted |

Uniform matte |

Industrial equipment, reduced glare |

Functional Considerations

● Battery Insertion and Removal:A textured interior can increase friction, making batteries harder to eject. For products where users frequently swap cells, opt for a smoother cavity finish.

● Contact Surfaces:The finish on metal contacts matters too. Nickel plating provides corrosion resistance. Gold plating reduces contact resistance but increases cost. For budget-conscious designs, nickel-plated steel strikes the right balance.

● Marking and Labeling:Polarity symbols, logos, and regulatory markings are often molded directly into the holder. Textured surfaces make these details more visible without adding printing or labeling steps.

Post-Processing Options

● Painting: Adds color but can chip over time

● Pad printing: Applies logos or instructions to small areas

● Laser marking: Permanent, high-contrast marking for critical information

If your holder will be visible in the final product, request a textured finish to hide minor imperfections from the molding process. It's cheaper than polishing and looks professional.

Battery Holder Prototypes: From Concept to Production

Getting a custom battery holder right the first time is rare. Prototyping lets you test fit, function, and durabilitybefore investing in production tooling. The method you choose depends on your timeline, budget, and how close you need the prototype to match the final product.

Prototyping Methods Compared

|

Method |

Lead Time |

Cost per Unit |

Best For |

|

3D Printing (FDM/SLA) |

1-3 days |

$5-$50 |

Early concept validation, form-fit checks |

|

CNC Machining |

3-7 days |

$50-$300 |

Functional testing in production materials |

|

Vacuum Casting |

5-10 days |

$20-$100 |

Small batches (10-50 units), investor samples |

|

Rapid Tooling |

2-4 weeks |

$15-$50 |

Bridge production, 500-5,000 parts |

3D Printed Battery Holder

For early-stage design, nothing beats 3D printing for speed. You can go from a CAD file to a physical part in under 24 hours. FDM printers work well for rough fit checks, while SLA delivers smoother surfaces and tighter tolerances.

The catch? Most 3D printing materials can't handle high temperatures or repeated mechanical stress. A printed holder works fine for verifying dimensions, but won't survive soldering or long-term use in demanding environments.

CNC Machining Battery Holder

When you need a functional prototype in theactual material you plan to use for production, CNC machining is the answer. You can machine battery bracket holders from polypropylene, nylon, ABS, or even aluminum for metal enclosures.

CNC prototypes cost more per unit than printed parts, but they behave like the real thing. You can test contact pressure, insertion force, and mechanical durability with confidence.

Rapid Tooling for Battery Holders

Rapid tooling bridges the gap between prototyping and mass production. Instead of investing $10,000+ in hardened steel molds, you use aluminum or soft steel tooling that can produce 500 to 5,000 parts.

This approach makes sense when you need:

● Production-representative parts for customer testing

● Small batch manufacturing before committing to full tooling

● Quick iteration on mold design without massive cost penalties

Don't skip the prototype phase to save time. Fixing a design flaw in CAD costs nothing. Fixing it in a hardened steel mold costs thousands.

Plastic Battery Holder Box: Enclosure Options

Sometimes a standalone battery holder isn't enough. You need a complete plastic battery holder box that encloses the cells, protects circuitry, and integrates with your product housing. These enclosures range from simple snap-together cases to custom-molded assemblies with built-in contacts and sealing features.

Types of Battery Case Holders

Integrated Compartments

Many handheld devices use battery compartments molded directly into the product housing. This eliminates the need for a separate holder and reduces part count. The trade-off is that the entire enclosure must be redesigned if battery requirements change.

Standalone Battery Boxes

For modular designs, standalone battery boxes mount inside or alongside the main enclosure. These are available in standard configurations for AA, AAA, 9V, and coin cell batteries. They typically feature:

● Snap-fit or screw-mount installation

● Spring contacts or pressure terminals

● Covers with latch mechanisms for easy battery access

Custom Enclosures

When off-the-shelf options don't fit, custom injection-molded enclosures provide complete design freedom. You can integrate:

● Unique form factors tailored to your product

● Sealed compartments for IP-rated protection

● Insert-molded contacts to reduce assembly steps

● Branding, regulatory markings, and polarity indicators

Material Selection for Battery Enclosures

|

Material |

Properties |

Typical Use |

|

ABS |

Impact resistant, cost-effective, UL94 flame rated |

Consumer electronics, handheld devices |

|

Polycarbonate |

High strength, transparent options, heat-resistant |

Medical devices, industrial equipment |

|

Polypropylene |

Chemical resistant, flexible, low cost |

General-purpose holders, toys |

|

Nylon (PA66) |

High mechanical strength, wear-resistant |

Automotive, rugged applications |

Design Considerations

● Thermal Management:Batteries generate heat during discharge. Enclosed battery boxes can trap this heat, leading to reduced performance or safety risks. Design venting channels or use materials with good thermal conductivity to dissipate heat effectively.

● Cell Swelling:Lithium pouch cells can swell up to 10% over their lifespan. If your enclosure doesn't account for this expansion, the housing may crack, or the cells may become difficult to remove. Build in clearance and consider flexible wall sections.

● Sealing and Protection:For outdoor or industrial applications, IP-rated enclosures protect against dust and moisture. Gaskets, ultrasonic welding, or adhesive sealing can achieve IP67 or higher ratings when properly implemented.

If you're designing a custom battery case holder, work with your manufacturer early. They can advise on draft angles, wall thickness, and parting line placement to avoid costly mold revisions later.

Build Better Battery Holders with TEAM Rapid

Designing a battery holder sounds simple until you're knee-deep in contact failures, warped housings, and tolerance headaches. The details matter. From material selection to surface finish, every decision affects whether your product performs or fails in the field.

Key takeaways:

● A battery holder secures cellsand maintains reliable electrical contact

● Choose holder type based on battery size, mount style, and application environment

● Materials range from standard polypropylene to high-temp PBT and LCP for soldering

● Prototype with 3D printing or CNC machining before committing to injection mold tooling

● Surface finish impacts battery insertion, grip, and overall durability

● Contact materials (nickel-plated steel, phosphor bronze, gold) determine conductivity and corrosion resistance

Whether you need a handful of prototypes or tens of thousands of production units, TEAM Rapid has the capabilities to deliver. From CNC-machined samples to injection-molded plastic battery holder boxes, we help engineers move from design to finished parts in days.

ISO 9001:2015 certified, 40% lower costs than Western suppliers, and 24/7 engineering support. Upload your CAD files and get a quote within 24 hours.

Frequently Asked Questions

What is a battery holder called?

A battery holder goes by several names depending on the application. You might hear it called a battery bracket,battery case,battery compartment,battery clip, or battery mount. In technical documentation, terms like "battery retainer" or "battery socket" are also common.

The naming often reflects the mounting style or form factor. For example, coin cell retainers hold button batteries flat against a PCB, while battery snaps connect to 9V cells via spring-loaded terminals.

What does a battery holder do?

A battery holder serves two critical functions. First, it physically secures the battery inside a device, preventing movement, rattling, or accidental ejection. Second, it establishes electrical contact between the battery terminals and the device's circuit.

Without a properly designed holder, you'd have loose cells, intermittent power, and unreliable performance. Good holders also protect against reverse polarity, shield against leakage, and make battery replacement easy for end users.

What is the 40 80 rule for batteries?

The 40-80 rule is a charging guideline for lithium-ion batteries. It recommends keeping your battery's state of charge between 40% and 80% rather than fully charging to 100% or draining to 0%. This practice reduces chemical stress on the cells and can significantly extend battery lifespan.

Here's why it works:

● Charging above 80% increases voltage stress and accelerates cathode degradation

● Discharging below 20-40% causes lithium plating and raises internal resistance

● Shallow cycles (40-80%) can deliver 2,000+ charge cycles compared to 300-500 cycles with full 0-100% charging

Many smartphones and laptops now include "optimized charging" features that automatically limit charging to 80% for this reason.

What is an AA battery holder?

An AA battery holder is a housing designed to fit one or more AA-size cells (14.5 mm diameter x 50.5 mm length). These holders come in single-cell, dual-cell, and multi-cell configurations, with options for series or parallel wiring.

Common mount types include PCB mount, panel mount, and wire lead versions. AA holders are used in everything from remote controls and flashlights to industrial equipment and medical devices.