Differences between Soft and Hard Tooling

Tooling and machine tooling are the backbone of manufacturing and molding process. Tooling refers to creating different type of component and machinery which are need for manufacturing. For example, molds, jigs and fixtures.“Tool”and“Tooling”means many different things in a wide range of area which is industry and manufacturing. For example, in the tool and die industry, tools can be dies which are used in production and the real mechanical tools which cut and shape parts. In composites industry, composite tools are the mold which layups are used to create the end products. Effective tooling allows to produce parts with proper function, extend the lifecycle of parts and increase the quality of products.

When it comes to tooling, a single size will not fit all. For example, urethane silicone molding and injection molding are common but require different tooling processes. If manufacturers mismatch tool type and mold process, they will be left with an inferior part.

Creating parts with reliable and high quality need a strong understanding of tooling process used to create the parts. So, we need to know the differences between soft tooling and hard tooling. And when to use soft tooling? When to use hard tooling?

What is Soft Tooling

Soft tooling is a cost-effective tooling method. It is widely used in cast urethane molding which allows manufacturers to create parts in small to medium volume in high speed. Silicone is one of the most commonly used soft tooling material for cast urethane. Silicone tooling is an ideal manufacturing to produce prototypes and parts in low volume.

Silicone tooling and the urethane process can be used when producing parts in a low volume which is ranging from 1 to 100 parts because the tooling and unit cost is more economical for low volume quantities. The cost of silicone tooling is usually around hundreds to thousands of dollars which depends on the part geometry. Silicone mold can be used to produce prototype, bridge and production of small quantity from one to hundreds of units. Most of silicone molds are great for around 25 shots each cavity. Silicone molds are injected with materials which is fed through a tube manually. Depends on the types of used material, it will take around 1 to 24 hours to cure. When is parts within the mold cure, the molds are opened manually and the surface finishing is done by hand if necessary.

Flexibility is one of the benefits of soft tooling because material requirements of soft tooling is flexible. If manufacturers produce parts by silicone tooling process, they don’t need to worry too much about compatibility. Silicone tooling is an ideal soft machining option to create prototypes and simple parts which are functional with a smooth surface finish. Soft tooling is also great manufacturing method to produce complex mold patterns which cost times to manufacture by other methods.

Silicone tooling is suitable for fast prototyping, tooling and part molding in many industries and designers all around the world as it provides the features they require:

1, Silicone tooling has great transparency so the object in the mold can be seen accurately. Silicone tooling is ideal for cut molds or two-part silicone tools.

2, Silicone has excellent clarity and easy coloration which can create great functional silicone parts.

3, Silicone has great mechanical properties which include great tear resistance.

4, Compared to artificial resins like PU, Epoxy and PES, silicone tooling can create high parts per mold yield because of high chemical resistance.

5, Silicone tooling has accurate reproduction of details. Parts can be released from the mold easily.

6, Silicone does not have shrinkage when cured. So, it offers accurate mold and part dimensions.

7, There are multiple catalyst system which offer great flexibility to make soft machining parts.

Silicone tooling is an ideal choice for low pressure injection molding application. Here at TEAM Rapid, our high-quality silicone are used in prototyping as its outstanding mechanical properties can meet critical requirement of production that long mold life and higher parts each mold yields are important to success.

As the materials used in soft tooling methods must be soft, the parts produce by this method are not so as durable and wear-resistant as hard tooling does. This is main limitation of soft tooling. For example, silicone tooling, it may not produce more than 25 parts until they swapped out for new tools. It is hard to make change to soft tools if the tooling is completed.

What is Hard Tooling

Hard tooling is a tooling method which is often sued for injection molding. Hard tools are made from durable and hard metal. For example, steel and nickel alloys. Hard tools are able to withstand several production cycles. It allows to produce parts in high volume quickly. Compared to soft tooling or silicone tooling, hard tooling is more suitable to produce parts which have high tolerance, test requirement and function standard. Hard tooling is ideal to create durable parts with high precision.

Compared to soft machining tooling, hard tooling is more expensive and time-consuming in terms of set up cost and production lead time. It is not cost-effective to use hard tooling for low volume production run or to produce parts and launch to the market as soon as possible. It takes more time to build hard tools as het need heat treatment, post-processing and extra machining to get the smooth finish. A smooth finish is important as it guarantees a seamless layup.

Steel or aluminum tools are used in injection molding process to create prototypes but mostly, they are used to produce parts in high volume which is ranging from 100 to 100,000 parts. The cost of steel or aluminum tools ranges from thousand to tens of thousand of dollars which will depend on the used materials and part geometry. The life of steel or aluminum tools is around thousand to millions of parts. Steel or aluminum tools are injected with materials from an injection mold machine. Compared to silicone mold, injection mold machine injects materials into the molds with less man power. It will take a few seconds to a few minutes cure materials so the it is quicker to create more parts compared to silicone tooling.

The speed of tooling

Here at TEAM Rapid, we are pound of ourselves to be a part of new way to develop composite tools which speed up the tooling process and save money. The new process combines what we do with composites with 3D printing.

3D printed composites need a lot of development by using 3D printing tools, we are able to get tools to customers quicker than before. We create prototypes on demand so speed up product development. We do all this very cost-effectively. Tooling is important to the composites industry. Composite fabricator cannot create parts quickly and cheaply without precision made tools.

Soft Tooling or Hard Tooling

To choose between soft tooling and hard tooling for your projects, engineers, designers and manufacturers have to consider the time of development and project requirements. Soft tooling is an ideal option if speed, flexibility and affordability are priorities. If manufacturers have blueprint that how to build parts with high precision and can afford expense and labor of hard tooling, hard tooling is an ideal option.

Differences between Soft and Hard Tooling

Tooling material is different

Silicone mold and injection molding are the most widely used molding process. These two processes request different types of tooling. Urethane molding produced parts from Soft Tooling (silicone) and injection molding produce parts from hard tooling (metal or aluminum). This article is about the difference between soft and hard tooling method which could help your project on time, within budget and give you proper function parts.

Molding volume is different

When coming to a low volume of quantity from 1 to 100 parts, soft mold and the urethane process are the ideal method because the tooling and part price is favorable for small quantities. Soft molds are also used for prototypes, bridge and production of small volume from 1 to 100 pieces. Soft molds are injected with material which is manually gravity fed through a tube which can take between 1-24 hours to cure. The molds are opened and applied finishing manually. Soft tooling injection molding has many advantages includes cost-effectiveness, short lead times and fast order turnarounds and a variety of material options. And a 3D-printed master pattern, minute details and complex geometries are quicker to implement into soft tooling compared to hard mold.

Production efficiency and costs are different

Hard Tooling are used for high volume injection molding process. Depending on tooling material and shape, steel or aluminum tools cost are thousands or ten of thousand of US dollar. Compared to soft mold, there is less labor as the machine injects mold into the mold. The hard mold yields parts faster than soft tools do. Hard tools help to facilitate high-volume production into the millions. Parts with simple designs may be used right off of the production. And a simple hard mold can have multiple cavities. Also, hard tooling molds can withstand higher temperatures, so they are suitable for materials which soft mold can‘t handle.

Comparison Table for Soft and Hard Tooling

| Feature / Aspect | Soft Tooling (Silicone / Urethane) | Hard Tooling (Metal / Aluminum) |

|---|---|---|

| Tooling Material | Silicone molds used for urethane molding; suitable for prototypes and small-volume parts. | Metal or aluminum molds used for injection molding; designed for durability and high-volume production. |

| Molding Volume | Ideal for low-volume production (1–100 parts). Quick to implement with 3D-printed master patterns. | Suitable for high-volume production (hundreds to millions of parts). Multiple cavities possible. |

| Production Efficiency | Labor-intensive: manual injection, curing 1–24 hours per part, manual finishing. Fast order turnaround for small batches. | High efficiency: machine injection, faster cycle times, less labor required. Can produce large quantities rapidly. |

| Cost | Low initial tooling cost, cost-effective for prototypes and small runs. | High initial tooling cost (thousands to tens of thousands USD), cost-effective only for large volumes. |

| Lead Time | Short lead time; quick design iterations possible. | Longer lead time due to complex mold machining, but efficient for mass production. |

| Material Options & Durability | Supports a variety of urethane materials; limited heat resistance. | Can handle high-temperature materials; suitable for durable, functional end-use parts. |

| Complexity & Detail | Can capture minute details and complex geometries quickly. | Better for simpler designs at scale; complex geometries possible but more costly. |

| Tolerance | ±0.3 mm to ±0.5 mm (depending on part size and material) | ±0.05 mm to ±0.2 mm (depending on part size and design) |

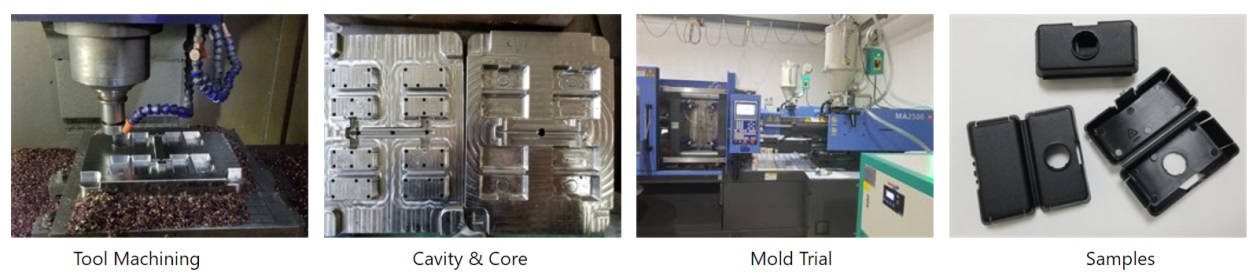

Tooling at TEAM RAPID

Here at TEAM RAPID, we help customers to place order and produce parts with efficiency and accuracy. Our professional team of engineers serve as your partner each step of the way. Our team of expert have more than 10-year experiences in the industry.We are a reliable manufacturer that provides high-quality soft and Rapid Tooling services. Our turnaround time for prototyping is sometimes as little as a few hours which could give our customers plenty of time to evaluate design, prepare for production. We also offer a variety of rapid manufacturing services, such as CNC machining, pressure die casting, and 3D printing. We help customers to choose the suitable and techniques to bring their ideas to life. And we help customer to innovate long into the future. If you want to learn more about soft tooling and hard tooling or want to have an instant free quote. Contact us today.

FAQs — Soft vs. Hard Tooling

1. What is the main difference between soft and hard tooling?

The main differences are in the tooling materials, cost, lead time, production volume, and precision.

- Soft tooling uses silicone or urethane mold sand is ideal for prototypes or low-volume production.

- Hard tooling uses metal or aluminum molds for high-volume, durable production.

2. Which tooling is better for prototypes?

For prototypes, soft tooling is better. Besides from the low-cost, fast to produce, and easy to modify. It can capture fine details and complex geometries without high investment.

3. Can soft tooling be used for functional parts?

Yes, soft tooling can produce small batches of functional parts, but it is limited in durability, heat resistance, and high-volume capability compared to hard tooling.

4. How do I decide which tooling method is right for my project?

You need to take production volume, required tolerance, part material, lead time, and budget into consideration:

- Soft tooling is best for low-volume, fast-turnaround projects.

- Hard tooling is ideal for high-volume, high-precision production.