Two Types of Rapid Tooling for Prototyping

Rapid tooling has positive impact on prototyping process. With rapid tooling, designers can makesmall run prototypes. Rapid tooling is really one of the best way to develop new products for many manufacturers, businesses and industries. To use the rapid tooling process, it is necessary to understand which type of rapid tooling. Direct tooling and indirect tooling are the two mainTypes Of Rapid Tooling. Both of them have their own advantages and disadvantages. Some designers prefer direct rapid tooling process as they will get the many benefits. And others prefer indirect rapid tooling process. Rapid tooling allows manufacturer to make a tool or mold in a short time. Compared to traditional tooling, rapid tooling is quicker and streamlined. This article is about these two main types of rapid tooling. It will guide you which type is the best fit for your prototyping process.

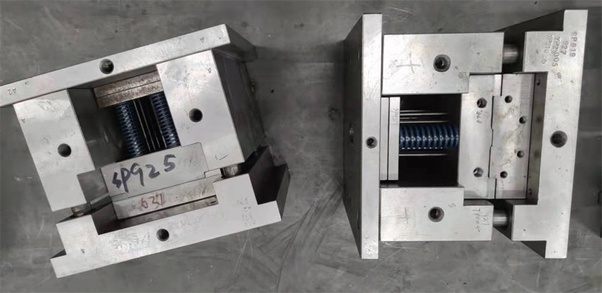

Direct tooling process has several steps. The first step is to create a tool or mold by CAD software. The second step is to send the send the file to the machine to produce real tool or mold which will be used to make prototypes. This is a process that a CNC machine cuts material to make the shape or a additive process that 3D printer print the parts from scratch. The mold or tool can be used to produce prototypes directly. Indirect tooling process has several steps. The first step is to build a model of master mold and tooling by software. The second step is to send the file to a machine or printer to build a master mold, tool or pattern. The third step is to make more molds or tools according to the master pattern. These molds or tooling can be made from different materials. The master pattern can be used for hard tooling or soft tooling. A single master pattern can produce different tooling or mold in high or low quantities. And also can produce many prototypes. The molds and tools can be used to make prototypes. In short, direct tooling is a quick and easy way to build tools or molds. Indirect tooling is time effective and require a few more steps or resources. Many designers want to use indirect tooling in prototyping stages.

Direct rapid tooling is more commonly used in mass production than rapid prototyping. In short-run production, direct rapid tolling allows manufacturers to build a mold or tool fast. It is beneficial for short run production as the tool does not need to be too durable. With these direct rapid tooling and depending on the material and the complexity level of the design, manufacturers can produce around 5,000 units. And these direct rapid tooling can be use to make prototypes.

Direct rapid tooling process is fast. Its lead time is short. It will only take a few days or weeks to complete the molds or tools. Multiple prototypes can be produce from a single mold or tool. Direct rapid tooling is very flexible. It allows manufacturers to make several mold or tools fast if the design is changed. But as there is no a master pattern, manufacturers need to build multiple tools or molds in different materials. And if the tool or mold is broken, or manufacturers need to test the new material, they will start the whole process again.

In the prototyping stage, indirect rapid tooling is more common compared to other types of rapid tooling. Indirect rapid tooling has various advantages. The master pattern is durable and it will not be damaged easily in prototyping process. If the design is not changed, manufacturer will invest one master pattern only. With indirect rapid tooling, hard or soft tools can be made. But compared to direct rapid tooling, indirect rapid tooling cost more time to produce. If the design will change during the prototyping stage, indirect rapid tooling is not a good option. It is not necessary for those design with high level of precision or accuracy. It requires high quality materials to make a durable master pattern.

TEAM Rapid is a leading prototyping manufacturer. We use the most advancedRapid Tooling and Rapid Prototyping methods and technologies to make prototypes. Contact our team of engineers at [email protected] to request a rapid manufacturing quote, we will provide suggestions on which types of rapid tooling to use according to your project requirements.