Why Choose Zinc Die Casting to Produce Customized Industrial Parts in 2025

Zinc die casting is used to make a wide range of parts within numerous kinds of industrial applications in 2024. Under normal temperatures, the mechanical properties of zinc die casting are superior to sand casting of grey iron, brass and aluminum, especially in toughness and strength. Zinc die casting parts are stronger, tougher and dimensionally stable than injection molded plastic parts. Zinc die casting parts are low cost and have improved properties. They are the better replacement for iron, copper, aluminum or plastic parts.

TEAM RAPID, as a professional zinc die casting parts manufacturer, we have ever made high quality zinc die casting parts for customers in different type of industries all around the world. Contact us for more information regarding for zinc die casting. We are happy to help you with any questions which you may have.

What is Die Casting Process

Die casting is a versatile, efficient and economical process to produce engineered metal parts. Die casting provides a wide range of shapes and components than other manufacturing technique. Die casting process require a steel mold. These reusable steel mold which is called dies. These dies can be designed to create parts with complex shapes and a high degree of accuracy and repeatability.

Zinc can be used bot hot and cold chamber casting processes. In zinc hot chamber die casting process, the injection mechanism of a hot chamber machine is immersed in a molten metal within a metal holding furnace. The furnace is attached to the machine by gooseneck. Around four or five shot output per minute can be produced by zinc hot chamber die casing process.

The cold chamber die casting process is opposite to the hot chamber method. Molten metal is poured into the cold chamber or cylindrical sleeve by ladle by cold chamber die casting. A plunger seals the cold chamber port and forces the metal into the die cavity under high pressure.

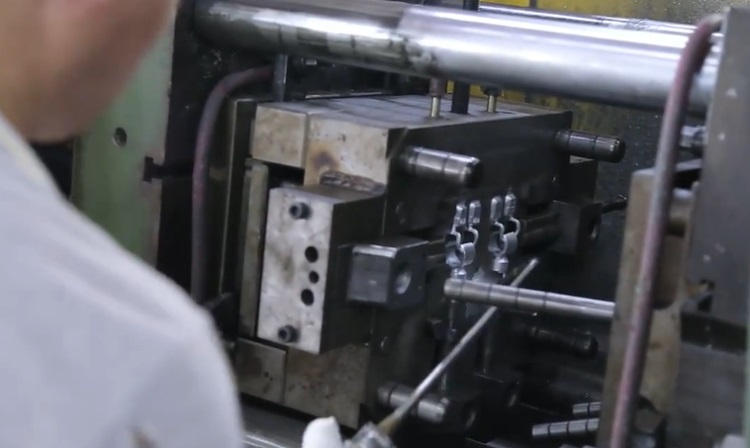

How is Zinc Die Casting Part Made

Steel dies are able to produce tens of thousand of zinc casting which must be made in at least two sections to allow the casting removed. These parts are firmly mounted in the machines and are arranged to make one is fixed and the other one is movable. The two mold halves are clamped together by a die casting machine to start the casting cycle. The molten zinc injected into the mold cavity and quickly solidified. The mold half is opened and the zinc casting is ejected. Zinc die casting mold may be simple or complicated. Depending on the complexity of the casing, zinc die casting molds can be with movable slide, cores or other parts. The complete cycle of zinc die casing is the fastest cycle to make precises zinc die casting parts. This contrasts to sand casting that need new sand mold for each casting. Permanent mold process uses iron or steel molds instead of sand, it is slower than zinc die casing. Permanent mold process is not as precise as zinc die casting.

What are The Advantages of Zinc Die Casting

Compared to other alloys, zinc die casting alloy has a better combination of strength, toughness, firmness, performance and cost-effective efficiency. The properties of zinc alloy die casing exceed other alloy like aluminum, magnesium, bronze, plastics and other cast iron.

Good Castability

As zinc die casting’s fluidity, zinc die casing can be produced thinner, intricate and more complex. Zinc die casting does not need secondary operations which are needed for aluminum and magnesium.

Short cycle time

As zinc use a hot chamber casting process, it has an output of around four to five shots per minute. Zinc die casting offer increased overall saving because of short cycle time compared to aluminum’s cold chamber die casing process which has an output of two or three shots per minute.

Long die life

As the low melting temperature of zinc, die for zinc parts can last up to ten time which is longer than aluminum casting die. And it is around five time longer than magnesium dies.

High quality

Zinc alloys are stronger than other metal. It doe not need secondary processing. This quality saves on the overall cost per unit.

Compared to other mass production processes, die casting process offers complex shapes with closer tolerance. Thousands of identical casting parts can be made in a short time.

1. Die casting parts are durable, dimensionally stable and heat resistant.

2. Die casting parts are stronger than plastic injection molded parts. Parts with thinner wall can be produced by die casing.

3. Die casting parts are smooth or textured.

4. Die casting provides simplified assembly by offer integral fastening factors like bosses, studs.

What are The Zinc Material Options

At TEAM RAPID, our engineers are able to die cast zinc Zamak #2, #3, #5, #7, ZA8 and ZA27. Zamak is characterized by impact strength and long term dimensional stability.

Zamak 2

Zamak 2 is the only Zamak which is used for gravity casting. It offers the highest strength and hardness of all Zamak alloys. Zamak 2 is a great bearing material and eliminate bushings and wear insert in die cast designs.

Zamak 3

When zinc die casting is considered, Zamak 3 is the first choice. Zamak 3 maintains a great balance of desirable physical and mechanical properties, castability and long-term dimensional stability.

Zamak 5

Compared to Zamak 3, Zamak 5 offers increased strength and hardness. In Europe, Zamak 5 is the most widely used zinc alloy.

Zamak 7

Zamak 7 is high-purity alloy which contains lower magnesium content. It maintains tighter impurity specifications. So, Zamak has improved casting fluidity, ductility and surface finish.

ZA8

Compared to the Zamak group of alloys, ZA-8 contains more aluminum. ZA-8 contains around 8.4% aluminum and is the only ZA allot which can be hot-chamber die cast. It is an important consideration when picking up a material for a part.

ZA27

ZA-27 contains more aluminum than the Zamak group of alloys. The number of 27 stands for the percentage of aluminum.

What are Zinc Die Casting Applications

As zinc is cost and time saving, it is commonly used in a wide range of industries for many applications. Some industries which regularly use parts produced by zinc die casting process include electronics, automotive, appliance manufacturers, mechanical design and more.

Some Items that Made in Zinc Die Casting

| Application | Examples of Zinc Die-Cast Parts |

|---|---|

| Automotive Components | Small bracket assemblies, mirror housings, seat belt lock components, pedal mounts, hinge housings |

| Consumer Electronics | Smartphone internal frames, camera brackets, tablet chassis, small cooling housings, connector shields |

| Industrial & Machinery | Gear housings, small pump bodies, valve brackets, lever arms, structural mounts |

| Home & Furniture Hardware | Door locks, window latches, knobs, drawer handles, furniture connectors |

| Plumbing & Fixtures | Faucet bases, shower valves, water flow regulators, small pipe fittings |

| Lighting & Electrical Fixtures | Lamp brackets, light fixture housings, switch plates, connector enclosures |

| Tools & Equipment | Hand tool handles, power tool casings, precision adjustment levers, support brackets |

| Medical Device Housings | External instrument shells, control panel brackets, lightweight support frames |

| Decorative Parts | Ornamental fittings, emblem badges, furniture trim pieces, designer knobs |

| Specialty Mechanical Parts | Small cams, gears, precision brackets, miniature frames, linkage components |

Contact TEAM Rapid for Zinc Die Casting Today

Need high-precision, durable, and visually perfect zinc die-cast parts? At TEAM RAPID, we delivers fast, cost-effective solutions from prototype to production.

-

Expert guidance on design and tooling

-

Quick turnaround for small or large runs

-

Premium surface finish and dimensional accuracy

Contact us for more information regarding zinc die casting options and zinc die casting processes. Our professional engineers will offer a free quote for rapid manufacturing.

Frequently Asked Questions (FAQ) – Zinc Die Casting

Q: How fast can I get zinc die-cast parts?

A: Lead time depends on part complexity and quantity, but TEAM RAPID focuses on fast turnaround. Prototypes Tooling parts can often be delivered in a few weeks, while production runs are optimized for speed without sacrificing accuracy.

Q: Can zinc die-cast parts be post-processed?

A: Absolutely. Zinc die-cast parts can be polished, plated, painted, coated, or machined after casting to meet aesthetic, functional, or protective requirements.

Q: Can TEAM RAPID handle both prototypes and production runs?

A: Yes. We specialize in prototype runs, bridge tooling, and high-volume production. This flexibility allows clients to test designs quickly and scale up efficiently without compromising quality.

Q: How do I know if my part is suitable for zinc die casting?

A: Parts with complex geometry, thin walls, fine details, or tight tolerances are excellent candidates. Our engineers review your designs and provide feedback on manufacturability and optimization to ensure the best results.

Q:Zinc vs. Aluminum Die Casting, How to Choose?

A: Zinc die casting is ideal for small-to-medium parts with complex shapes, thin walls, and high precision, offering excellent surface finish and durability. Aluminum die casting, on the other hand, is lighter, better for larger or thicker parts, and provides good thermal conductivity.