Save Your Cost by Vacuum Casting Method in 2024

Vacuum casting, also called polyurethane casting, it is a good method to satisfy your low volume production needs at a low cost, you can have 10 or several hundred custom parts in a short time, it is one of Prototyping China processes 2024.

Vacuum casting is suitable for low volume manufacturing. Comparing with investing a steel or aluminum mold, the cost of silicone mold is much less. We may just need 1/3 or less cost to get your small volume plastic parts. Also, the lead-time for vacuum casting is short, it will be a good for you to have a quick turnaround.

The Main 3 Steps of Vacuum Casting Process.

1. Make a master model

CNC machining and 3D printing are the main processes to make master model, post finish is necessary if the casting part needed in gloss or texture.

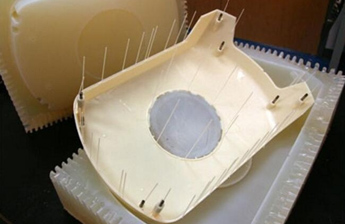

2. Create a silicone mold.

a: Make up the silicone according to the instruction, then discharging the moisture content under vacuum condition.

b: Make a custom box, the size of that box should be 20mm bigger than the master part.

c: Fix the master part into the box, then pour the prepared silicone into the box. Discharge the moisture again under vacuum condition.

d: It takes 1 to 4 hours to cure the silicone under 60~70 degrees Celsius in the oven. Then we split the mold by knife and take out the master part, the finish on master will be transferred onto cavity.

Vacuum casting mold lifetime ranges from 10 to 20 shots varies based on the part geometry and casting material.

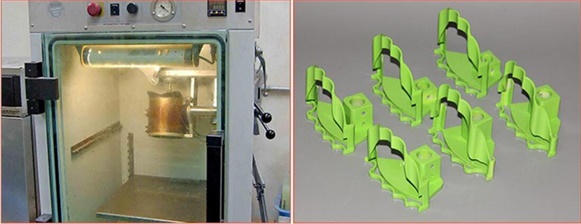

3. Casting the part.

Most of plastics are available in Prototyping China, technical parameters for Casting part:

casting material:Polyurethane(Brand: AXSON, Hei-cast).

casting material Type: ABS-liked, PP-liked, PA-liked, PMMA-liked, etc., Rubber(40~90 shores).

part cured time: 30~60 mins depend on the part size and casting material & conditions.

part tolerance: +/-0.2mm/100mm.

casting wall thickness: minimum at 0.5mm, 1.5mm to 5mm is good for casting.

maximum casting size: 2000mm x 1200mm x 1000mm.

Contact TEAM Rapid for Vacuum Casting Service

TEAM Rapid offers the best rapid prototyping services in China. Vacuum Casting, CNC Machining, Injection Molding, Die Casting are our main services, we can offer 1 to 10,000+ custom parts in plastic and metal with low cost but high quality. If you are interested in vacuum casting process and our services, contact us to request a rapid manufacturing quote.